What is lithium battery paste?

Lithium battery paste is a lithium ion battery material, mainly composed of lithium ion battery positive electrode material, binder and conductive agent. Lithium battery cathode materials usually use oxides, such as ternary materials (such as LiCoO2, LiMn2O4, LiNi1/3Mn1/3Co1/3O2, etc.) or phosphate materials (such as LiFePO4), and binders usually use polymers (such as PVDF) , The conductive agent usually uses carbon black or conductive agent particles.

The application of lithium battery slurry is mainly in the field of lithium ion batteries, which is one of the important materials for manufacturing lithium ion batteries. Lithium battery is one of the commonly used rechargeable batteries at present, and is widely used in mobile devices, power tools, electric vehicles and other fields.

Method for preparing lithium battery slurry

There are two main methods for preparing lithium battery slurry: dry method and wet method.

Dry preparation of lithium battery slurry is to mix and stir the positive electrode active material, binder and conductive agent, and dry at high temperature to make a dry powder. The advantages of this method are simplicity and low cost, but it is easy to generate dust during the mixing and drying process, which is not conducive to the health of workers.

The wet preparation of lithium battery slurry is to dissolve the positive electrode active material, binder and conductive agent in an appropriate amount of solvent, and add a surfactant and a dispersant to form a mixed slurry. The mixed slurry is then added to a mixer for mixing and stirring, and dispersed using ultrasonic waves or high-shear equipment to finally form a uniform slurry. The advantage of this method is that it can prepare a uniform slurry and can control the particle size and distribution, but it needs to consume more cost and time.

Lithium battery slurry is one of the key materials for manufacturing lithium-ion batteries, and its quality and performance have an important impact on the performance and life of the battery.

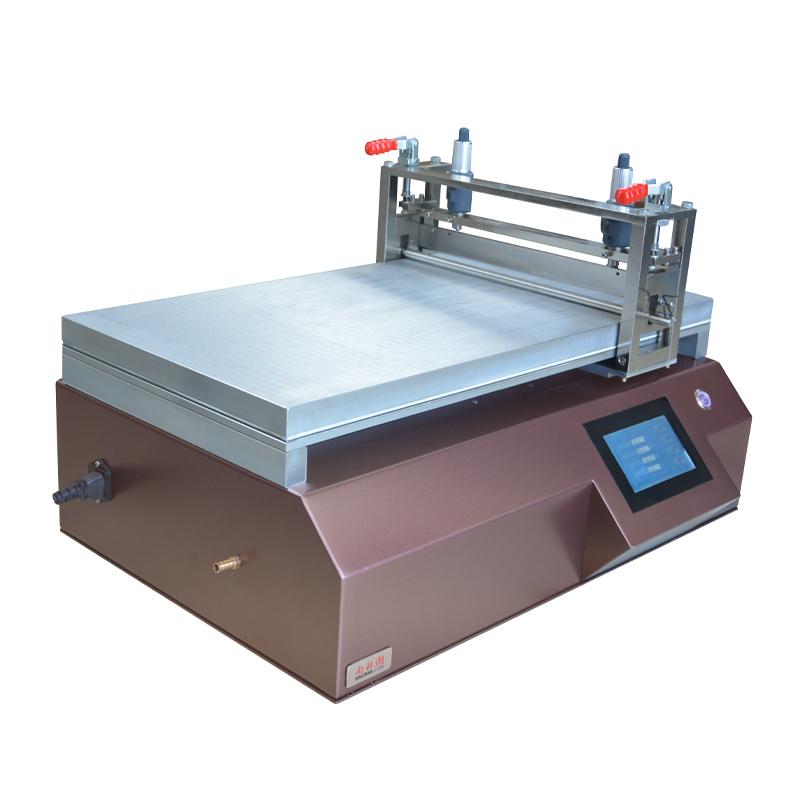

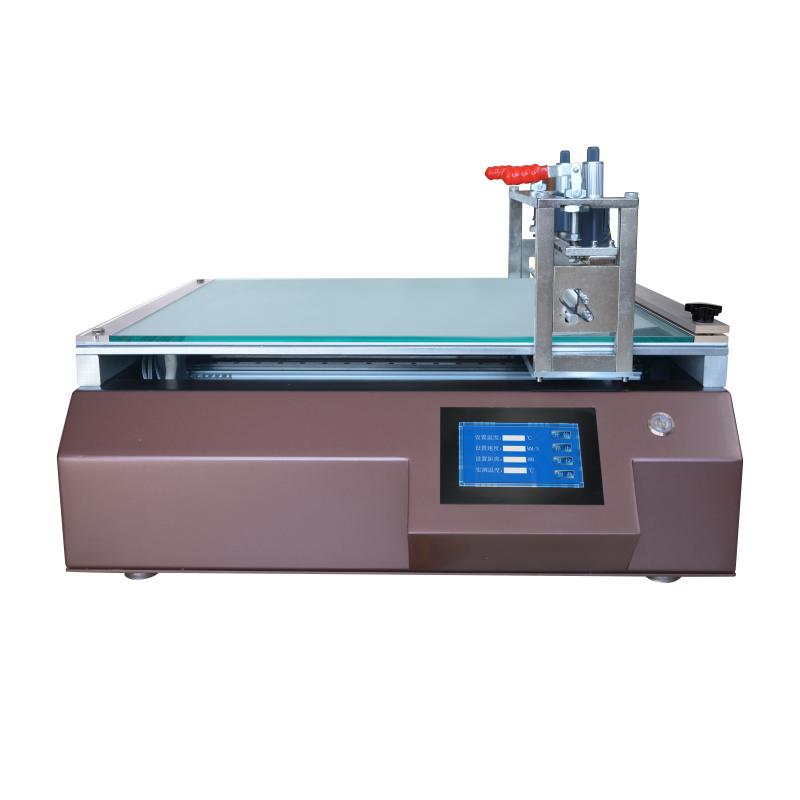

Application significance of film coating machine

In the film-making application of new energy lithium batteries, the film coating machine can achieve uniform coating of battery materials such as positive electrodes, negative electrodes, and diaphragms, thereby forming high-quality battery sheets. The application of film coating machine can greatly improve production efficiency and production quality, and reduce production costs.

Membrane method

The film forming method of the film coating machine in the new energy lithium battery includes the following steps:

First, the positive electrode, negative electrode, diaphragm and other battery materials are coated on the substrate, and the parameters such as coating speed, pressure and coating method are controlled by a film coating machine to achieve uniform coating of materials;

Laminate the coated battery material sheets, and perform pre-compression, cutting and other treatments to prepare battery sheets;

The battery sheet is packaged in a steel case or a soft package to obtain a finished lithium battery.

Advantages of film coating machine

The coating machine has the following advantages in the manufacture of new energy lithium batteries:

Effective: The coating machine can automatically complete the coating process, greatly improving production efficiency;

High precision: the film coating machine can accurately control coating parameters to achieve uniform coating of materials, thereby improving production quality;

Good repeatability: the coating machine can accurately replicate the same coating process to ensure the consistency of each cell.

In short, the film coating machine has important application value in the manufacture of new energy lithium batteries, which can improve production efficiency and production quality, and is an indispensable part of the modern lithium battery manufacturing process.