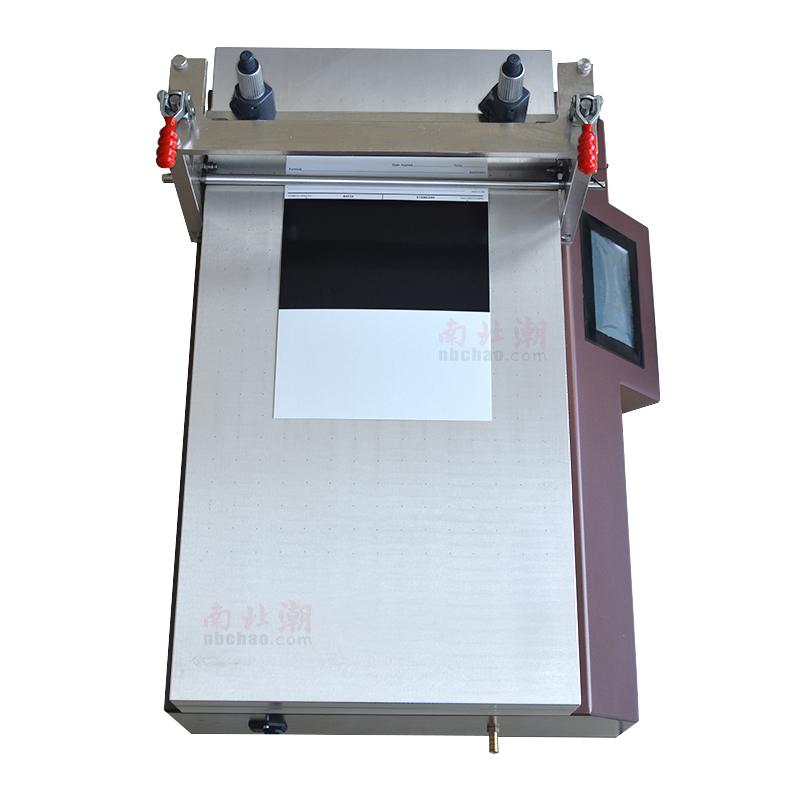

A Film Applicator is an automated device that can be used for the film application of self-adhesive waterproofing membranes. Self-adhesive waterproof membrane is a material commonly used in construction and engineering fields, with good waterproof performance and adhesion performance.

Membrane method

There are generally two methods for preparing self-adhesive waterproof membrane coatings: wet coating and dry coating. The wet coating method refers to brushing or spraying the paint on the surface of the substrate, and drying it to form a thin film through volatilization or chemical reaction. The dry coating method refers to coating the pre-prepared film directly on the surface of the substrate.

High-quality, uniform coating can be achieved by using a Film Applicator. The working principle of the film coating machine is to apply the paint on the surface of the substrate, and then use the machine to automatically and evenly sweep the paint to form a thin film. The coating machine can control the thickness and quality of the coating film by adjusting parameters such as coating speed, pressure and blade angle.

In the preparation of self-adhesive waterproofing membranes, commonly used coatings include hot melt adhesives, SBS (polystyrene-styrene-butadiene rubber-polystyrene) and APP (polypropylene-acrylate copolymer), etc. By adjusting the parameters of the film coating machine, different coatings can be applied to prepare self-adhesive waterproof membranes with different properties.

To sum up, the Film Applicator is a reliable and effective tool for the film application of self-adhesive waterproofing membrane and its film making method.