From the analysis of the causes of pores, the method to prevent pores is firstly to reduce the amount of solvent per unit area, so the coating film should not be too thick; secondly, the surface of the coating film should maintain fluidity during the drying process. In this case, even if the volatile gas of the solvent passes through, the formed pores will be filled by themselves. For this reason, it is necessary to use a solvent with a slow drying speed, and at the same time, the drying speed of the surface and interior of the coating film should be balanced; Submersibles vaporize large amounts of solvent. The following specific analysis.

The coating film should not be too thick

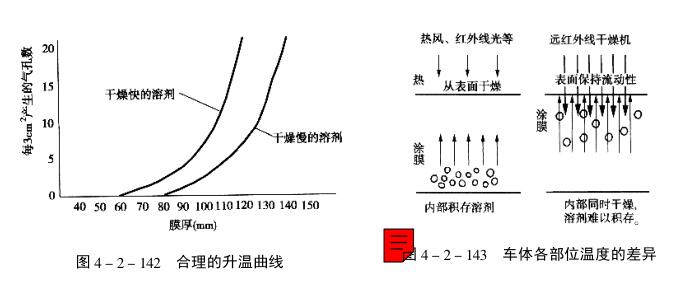

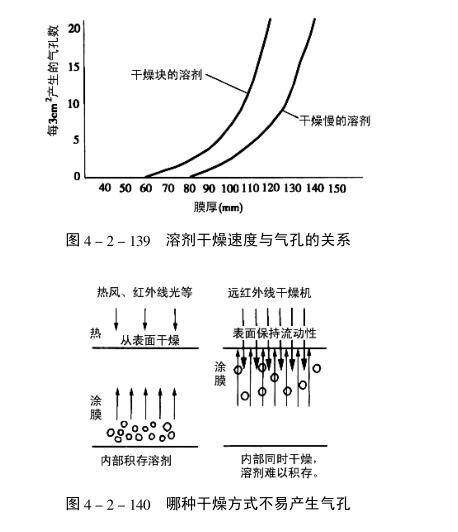

It can be known from experience that if the sprayed film is thin, pores are not easy to appear even if the temperature rises sharply. Figure 4-2-137 is the verification experiment result for this. In this experiment, the same diluent and the same dilution rate are used, only the number of sprays is changed, that is, the thickness of each spray is changed, and the coating comparison experiment is carried out. (Related instrument: coating Thickness Gauge) After spraying, use the same interval time and the same heating method to check the number of pores after drying, and draw Figure 4-2-137. It can be seen from the graph that, under the same premise of other conditions, the thicker the coating film is, the easier it is to generate pores. The reason is as shown in Figure 4-2-138, the thicker the coating film, the more solvent will be contained in the same size area, so the more gas will be generated.

In addition, usually the velocity of the solvent gas rising from the interior to the surface of the coating film is inversely proportional to the square of the distance. If the film thickness is doubled, the evaporation rate becomes 1/4 of the original, that is, the time for the solvent to remain in the coating film is 4 times of the original. If heated, a large amount of residual solvent evaporates rapidly, and it is easy to form pores. Therefore, doubling the film thickness not only doubles the amount of solvent gas, but also increases the time that the solvent remains in the coating film, which makes the possibility of pores more likely. So from this point of view, the thickness of each spray should be as thin as possible. But sometimes it is necessary to ensure the surface quality (gloss, etc.) and also need to spray a certain thickness. In this case, two factors must be considered in the specific operation.

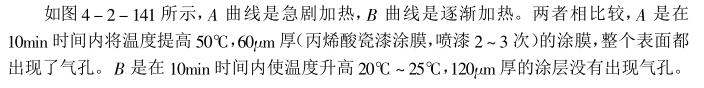

The influence of diluent is easy to misunderstand that thinner with fast drying speed will not remain inside the coating film, so pores are less likely to appear. But in fact, using a slow-drying thinner is less prone to pores. The comparison between the two is shown in Figure 4-2-139.

If a fast-drying thinner is used, the surface of the coating film will dry quickly, which will hinder the evaporation of the internal solvent and make it remain inside the coating film. In summer, if you use a fast-drying thinner without any heating measures, it will be full of pores. This is the reason.

Therefore, in order to prevent the occurrence of pores, a thinner that does not dry quickly on the surface of the coating film should be used to maintain the fluidity of the surface of the coating film.

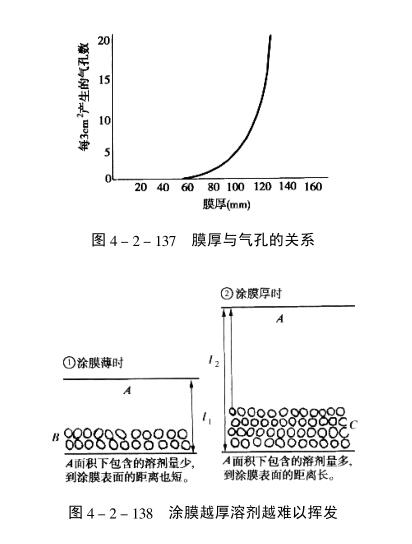

Heating with far-infrared heaters is not easy to produce pores

If infrared bulbs with a relatively short heating distance are used for heating, air holes will often occur in places with thicker coatings such as hoods, roofs, and trunk lids. Using a far-infrared heater with better performance and heating under the same conditions, pores are less likely to appear. This is because the far-infrared heater has the property of drying the paint from the inside. The hot air dryer and the infrared dryer start drying from the surface of the coating film, while the far-infrared dryer dries from the surface and inside simultaneously as shown in Figure 4-2-140. Even if solvent gas is generated, due to the fluidity of the surface, No blowholes are caused by this either. However, this is only a theoretical judgment. In fact, it cannot be concluded that far infrared has better performance than hot air and infrared.

The control of drying temperature is the decisive factor

Even when the surface of the coating film is dry, there are gaps that are invisible to the naked eye. If the amount of solvent vapor generated is controlled to the extent that it can just evaporate outward through the above-mentioned gap, no pores will appear. For this reason, when performing drying operations, it cannot be heated rapidly. As long as this is done, the generated solvent vapor will be less and gradually evaporate, and then it can be gradually discharged through small gaps invisible to the naked eye.

The heating and drying method varies with the structure of the spray booth and the type of dryer, and there is no so-called good method.

However, it can be compared by measuring the temperature of the car body to find out the conditions that neither produce pores nor dry faster. (Related instrument: drying time Tester)

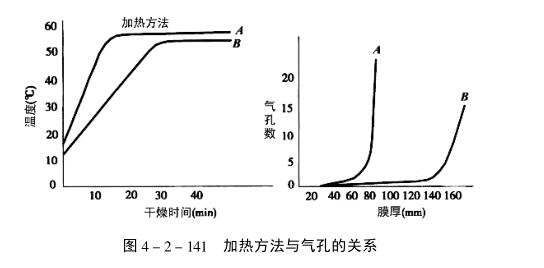

This method of heating has the greatest effect on porosity generation. Curves A and B are called heating curves, which have a great influence on paint baking and forced drying. The steeper the curve, the easier it is for pores to appear, and the gentler it is, the less likely it is for pores to appear. But if it is too gentle, although pores are not easy to appear, the drying speed is too slow. As shown in Figure 4-2-142, finding a reasonable heating curve within the range shown in the figure is the key to increasing the drying speed.

The determination of the so-called drying temperature should be based on the body temperature. The temperature of the air in a paint booth with infrared and far infrared drying is of little significance. Because the radiant heat emitted by this dryer starts to be generated when the rays hit the car body, even though the air temperature is still low, the car body has reached a higher temperature. In addition, it should also be noted that the upper part of the roof, engine cover, etc., is not the same temperature as the lower skirt of the car body. As shown in Figure 4-2-143, it is an example of measuring the temperature of the air in the spray booth, the temperature of the roof and the temperature of the lower skirt of the car body. Therefore, in order to accurately control the drying temperature, it should be clear in advance how the temperature of each part of the car body will change with the change of the distance between the dryer and the car body and the on-off of the bulb of the infrared heater.