What is a transfer film?

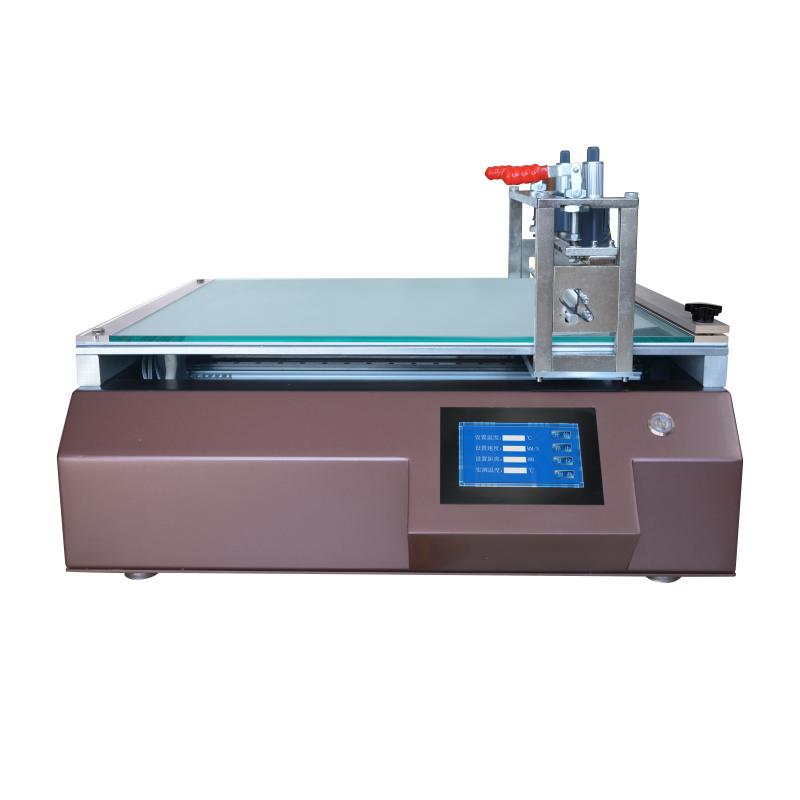

The transfer film is an intermediate carrier that exists on the transfer paper base or plastic base, carrying the printed or printed pattern, and is used to transfer to a layer of chemical elastic film on the printed article. The film coating machine can be applied to the preparation of transfer film.

Membrane method

The following are the coating application of the transfer film and its film making method:

Prepare the substrate: the transfer film needs to be coated on the substrate, which can be a metal plate, a plastic plate, etc. The substrate needs to be dry, clean, flat, and have a smooth surface.

Preparation of transfer film: Put the transfer film material into the film coating machine, and adjust the parameters of the film coating machine, such as film coating speed and film pressure, according to the required film thickness and coating speed.

Coating: Start the Film Applicator to allow the transfer film material to be evenly coated on the substrate. Different application methods can be used, such as knife coating, spraying, etc.

Drying: After the coating is completed, put the substrate into the drying chamber for drying, so that the transfer film material can form a firm film on the substrate.

Printing: Printing on the film can use different printing techniques such as screen printing, offset printing, etc.

Transfer: Peel the printed transfer film from the substrate and transfer it to the target substrate.

Hot pressing: Put the transfer film and the target substrate together into a hot press for hot pressing, so that the transfer film and the target substrate are tightly combined to form a beautiful and durable pattern.

In short, the film coating machine can realize the effective coating of the transfer film, improve production efficiency and product quality. During the coating process, the parameters of the coating machine need to be adjusted reasonably to achieve the required coating thickness and coating quality. Through subsequent processes such as drying, printing, transfer and hot pressing, the required transfer film can be obtained.