Film applicators play an important role in the application of high-gloss films. High-gloss film is a film material with high transparency, high brightness and high reflectivity, which is usually used in optics, electronics, construction, automobile and other fields. The use of the film coating machine can achieve effective and uniform coating and ensure the quality and performance of the high-gloss film.

Membrane method

The film-making method of high-gloss film mainly includes the following steps:

Material preparation: Mix polymer materials and organic solvents in a certain proportion to prepare a high-gloss film solution.

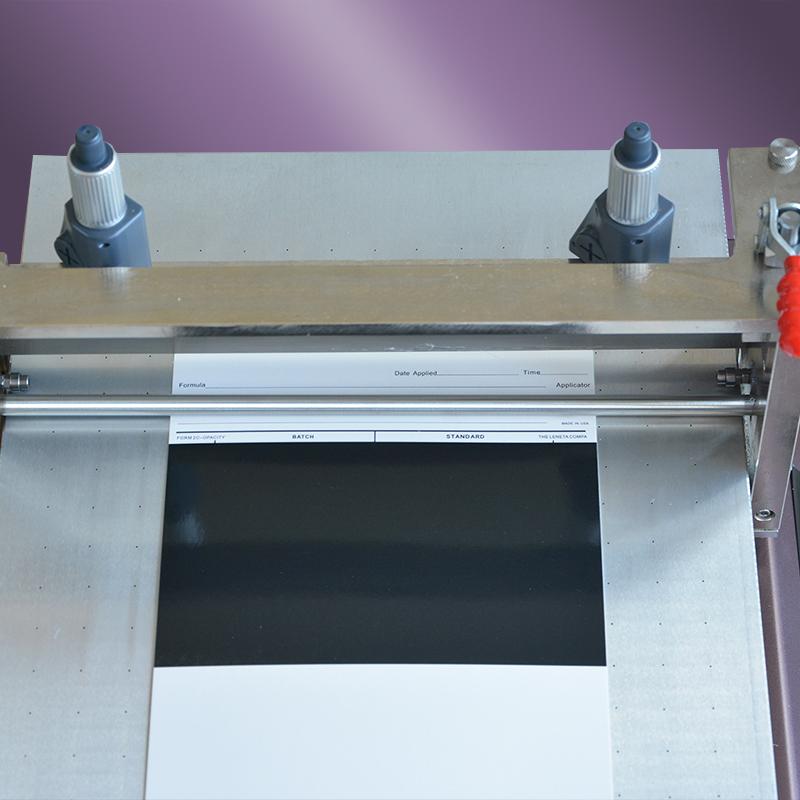

Coating: Pour the high-gloss film liquid into the coating tank of the coating machine, set the coating thickness and coating speed and other parameters, turn on the coating machine, and evenly coat the coating on the surface of the substrate.

Curing: Through heating, ultraviolet radiation, etc., the high-gloss film liquid is cured and cross-linked to form a high-gloss film.

Application meaning

The use of film coating machine can realize the control of coating thickness, quality and uniformity, and then obtain good high-gloss film performance. Coating machines are usually equipped with scrapers of different materials and angles. The angle and position of the scrapers can be adjusted as needed to control the coating thickness and uniformity. The coating machine can also set coating speed, coating pressure, coating direction and other parameters according to the needs, so as to adapt to different high-gloss film preparation requirements.

In short, the film coating machine plays an important role in the application of high-gloss films, which can greatly improve the quality and efficiency of coating films, and provide a reliable means for the preparation of high-gloss films.