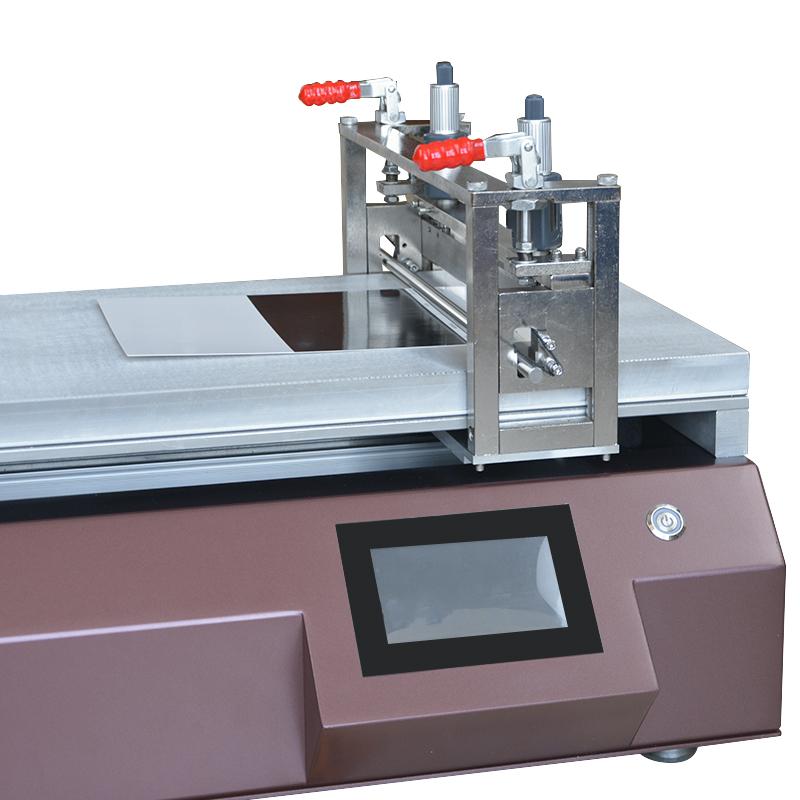

The film coating machine is widely used in the application of hot melt adhesive film, and is mainly used to prepare various hot melt adhesive film materials, such as hot melt adhesive film, hot melt adhesive composite film, etc. The use of the film coating machine can realize the uniform coating of hot melt adhesive and improve the performance and quality of hot melt adhesive film materials.

Membrane method

The film-making method of hot melt adhesive mainly includes the following steps:

Material preparation: heat the hot melt adhesive particles or block materials to a molten state to make it a liquid hot melt adhesive.

Coating: Pour the molten hot melt adhesive into the coating tank of the coating machine, set the coating thickness and coating speed and other parameters, turn on the coating machine, and evenly coat the hot melt adhesive on the surface of the substrate .

Curing: Through cooling, pressurization, etc., the hot melt adhesive is quickly cured to form a uniform hot melt adhesive film.

Application meaning

The use of film coating machine can realize the control of coating thickness, quality and uniformity, and then obtain good hot melt adhesive film materials. Coating machines are usually equipped with scrapers of different materials and angles. The angle and position of the scrapers can be adjusted as needed to control the coating thickness and uniformity. The coating machine can also set coating speed, coating pressure, coating direction and other parameters according to needs, so as to adapt to different hot melt adhesive film preparation requirements.

In short, the film coating machine plays an important role in the application of hot melt adhesive film, which can greatly improve the quality and efficiency of coating film, and provides a reliable means for the preparation of hot melt adhesive film materials.