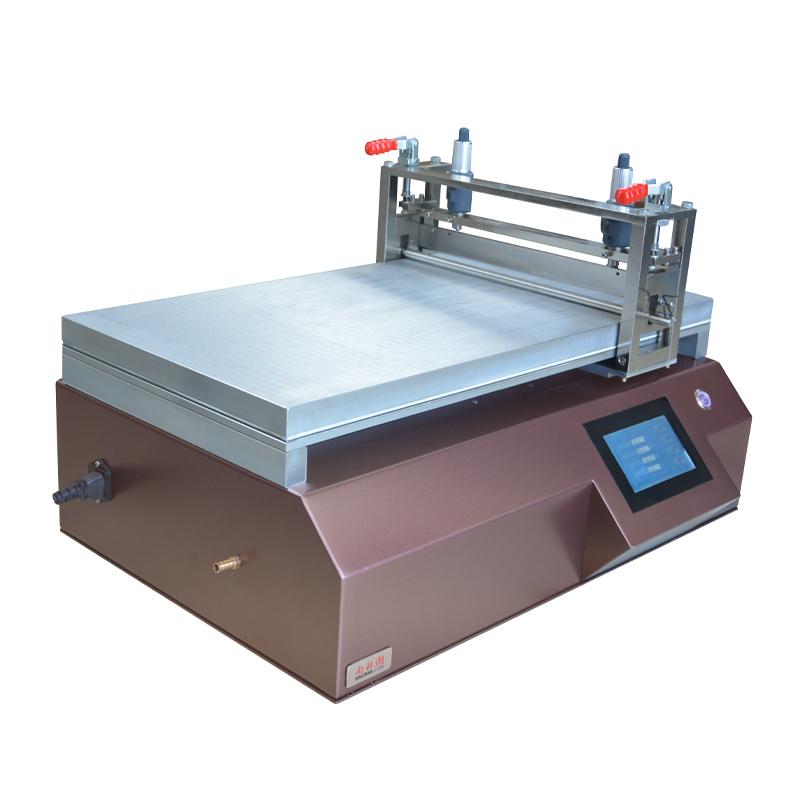

A Film Applicator is a device commonly used in laboratories or industrial production to evenly coat viscous liquids on the surface of substrates to prepare films or coatings. Proton membrane is a special membrane material, which has a wide range of applications in the field of energy and environmental protection, such as proton exchange membrane fuel cells, hydrogen production by electrolysis of water, etc.

The application of the film coating machine in the preparation of the proton membrane mainly involves the preparation of the precursor material for coating the proton membrane, that is, after the polymer or inorganic material containing the proton exchange group is dissolved in the solvent to form a solution, it is evenly coated by the film coating machine. It is clothed on the surface of the substrate and processed by heating and drying to form a proton membrane.

In the coating process of proton membrane preparation, the parameter setting and operation mode of the coating machine have an important influence on the quality and performance of the membrane. For example, the selection of parameters such as coating speed, pressure, and the angle of the coating head needs to be adjusted according to specific materials and preparation requirements.

In addition, the film coating machine can also be combined with other film-making methods, such as spin coating, spray coating, etc., for composite preparation to further improve the quality and performance of the proton membrane.

In a word, the coating machine plays an important role in the preparation process of the proton membrane, which can achieve effective and uniform coating and provide strong support for the application and development of the proton membrane.