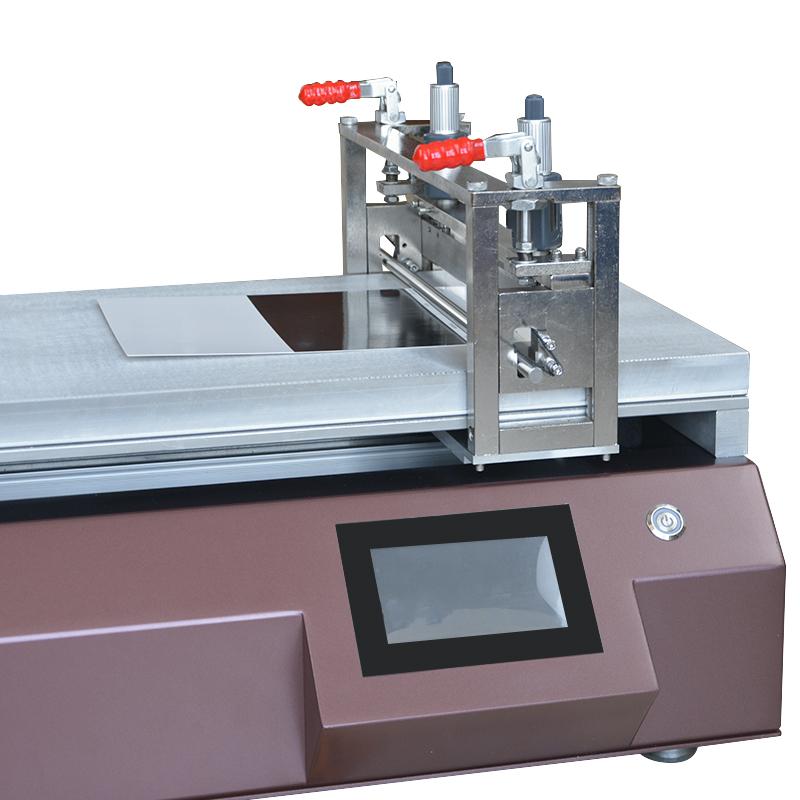

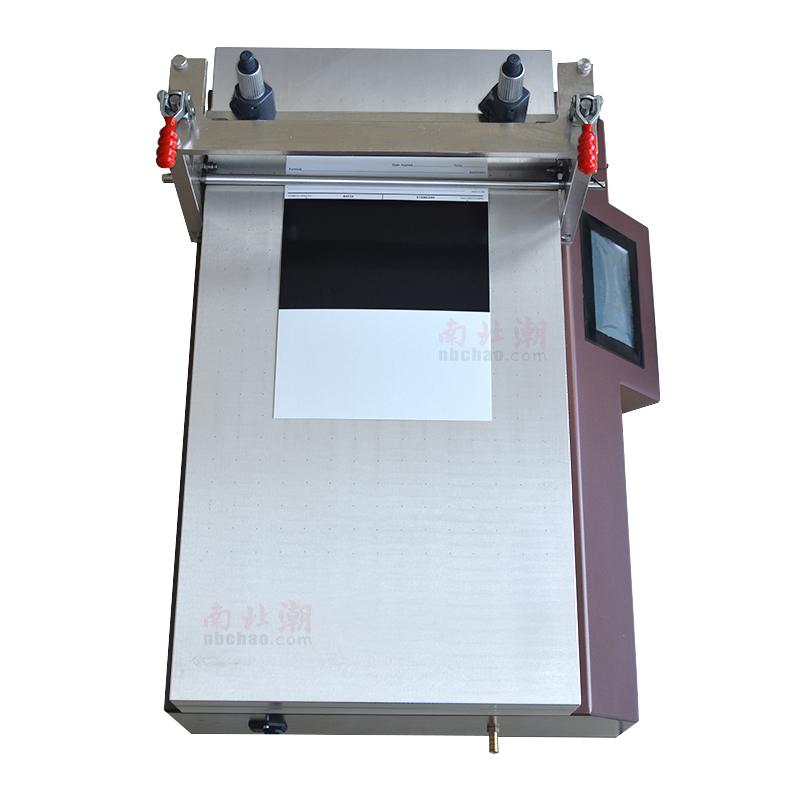

Coating machine is a kind of equipment commonly used in paper coating application, which can evenly coat the coating on the paper surface by controlling the coating head and rotating speed. A film coating machine usually consists of a coating head, a motor, a control system, and a film thickness measuring device.

Film applicators can be used for a variety of coating materials such as polymers, pigments, resins and coatings. Their range of applications covers many fields, such as packaging, construction, printing, electronics and medical treatment.

Membrane method

Film-making methods generally involve applying coatings to the surface of paper and converting the coatings into thin films by means of heat, pressure or chemical reactions. Among the common film-making methods include:

Solution Immersion Method: The paper is soaked in a liquid containing dissolved polymers, and the film is formed by evaporating the solvent in the solution.

Slurry Coating Method: The polymer slurry is coated on the paper surface, and then heated or dried to form a film.

Solution Coating Method: A solution containing a polymer is coated on the surface of paper, followed by heating or drying to form a film.

Chemical vapor deposition method (Chemical Vapor Deposition Method): chemical gas is deposited on the surface of paper, and then a film is formed by chemical reaction.

In short, the coating machine is an important equipment in the application of paper coating. It can achieve uniform coating of coating by controlling the coating head and rotating speed. At the same time, there are many methods of film production, and the suitable method can be selected according to different needs.