In the application of anisotropic conductive adhesive film coating, the film coating machine can realize effective and high-precision coating, improve the quality of coating film and production efficiency.

Membrane method

The following is the coating film preparation method of the anisotropic conductive adhesive:

Substrate preparation: select a substrate suitable for the application of anisotropic conductive adhesive, such as glass, plastic and other materials, and perform surface treatment to improve coating adhesion;

Preparation of coating stock solution: According to the formula requirements, mix polymers, conductive fillers, catalysts and other raw materials evenly, add an appropriate amount of solvent, and fully mix in a magnetic stirrer to form a coating film stock solution;

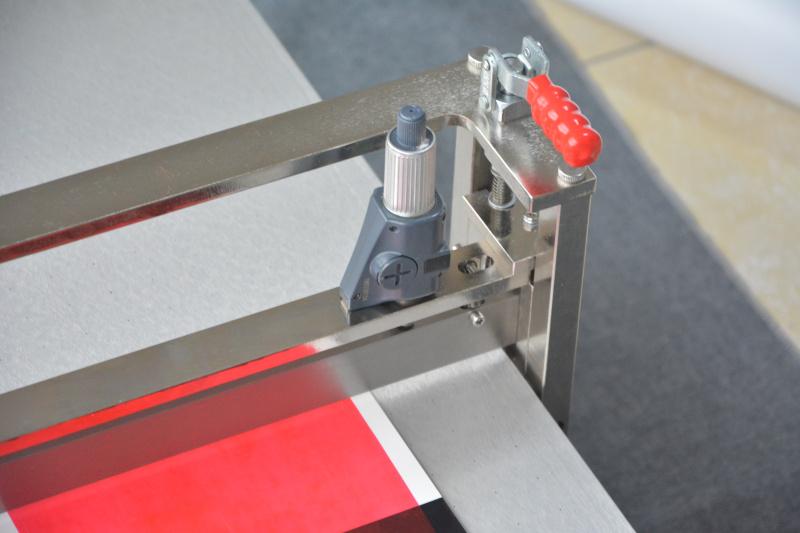

Coating machine coating: apply the coating stock solution evenly on the substrate to form a thin film;

Drying treatment: Place the coated substrate in a ventilated and dry place, or use an oven for drying treatment to remove solvent and moisture, and dry and cure the coating;

Hot pressing treatment: put the dried and cured coating into a hot press for compression and hot pressing treatment to make the surface smooth and smooth, and improve the adhesion between the coating and the substrate;

Cutting treatment: Cut the coating after compression and heat treatment into appropriate shape and size for subsequent assembly and use.

Value

In the film application of anisotropic conductive adhesive, the film coating machine is mainly used for coating anisotropic conductive adhesive to achieve conductive performance. The film coating machine has the characteristics of high precision, high speed and high repeatability, which can achieve accurate coating thickness and uniformity, and improve the quality of coating film and production efficiency. In the process of preparing the coating film of the anisotropic conductive adhesive, it is necessary to pay attention to controlling parameters such as coating thickness, coating speed, coating method, and drying time to obtain better coating film quality. At the same time, the substrate needs to be surface treated before coating to improve the adhesion and bonding performance of the coating. During the coating process, attention should also be paid to ventilation and fire prevention measures to ensure safety.