In the coating application of alumina passivation film, the film coating machine can realize the uniform coating of passivation liquid, thereby forming alumina passivation film and protecting the surface of aluminum alloy materials from corrosion and oxidation. Alumina passivation film is a commonly used surface treatment method, which is often used to improve the corrosion resistance and aesthetics of aluminum alloy materials.

Preparation

The preparation methods of aluminum oxide passivation film mainly include various methods such as chemical method, electrochemical method and physical method. Among them, the electrochemical oxidation method is a commonly used method. By adding a certain current to the passivation solution, the oxidant in the passivation solution is oxidized on the surface of the aluminum alloy material to form an aluminum oxide passivation film. The film forming process needs to control parameters such as the composition, temperature, current and time of the passivation solution.

Value

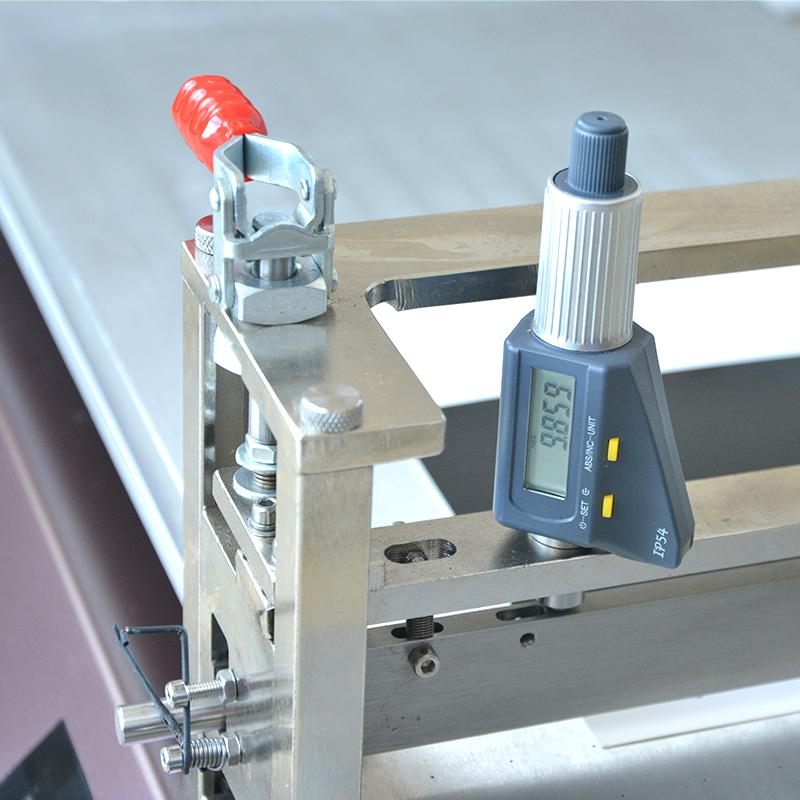

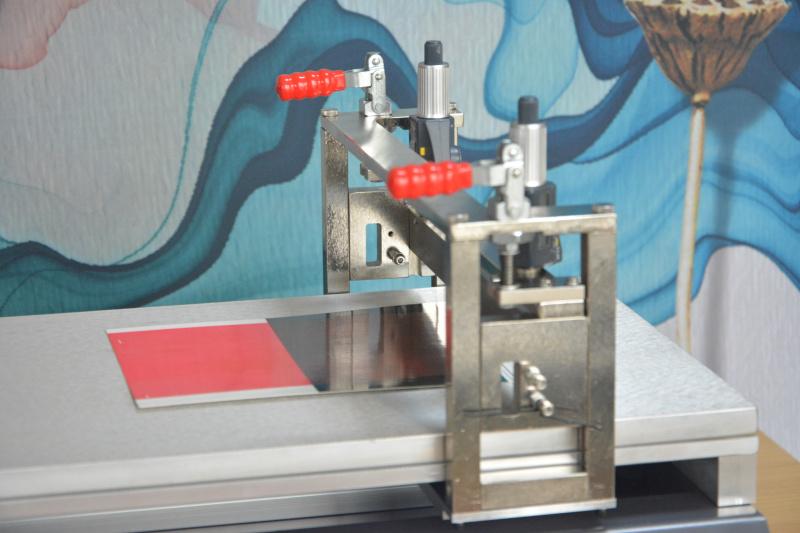

In terms of coating film application, the coating machine can achieve uniform coating of passivation solution by controlling parameters such as coating speed, pressure and coating method, so as to form a uniform aluminum oxide passivation film. Commonly used coating methods include roller coating, spraying and brushing. The coating machine can also adjust the thickness of the aluminum oxide passivation film by controlling the coating thickness, so as to adapt to different application scenarios.

In short, the coating machine plays an important role in the preparation and application of the alumina passivation film, which can realize the uniform coating of the passivation solution and improve the quality and performance of the alumina passivation film.