The film coating machine can improve the efficiency and accuracy of the coating operation in the application of cellulose film coating, and can choose the appropriate film making method according to different needs.

The following is the film making method of the film coating machine in the preparation of cellulose film:

Prepare the substrate: choose a suitable substrate, such as glass sheet, polyimide film, etc., and clean it.

Prepare the paint: Prepare the cellulose solution as needed.

Adjust parameters: adjust the parameters on the coating machine, such as coating speed, coating angle, coating pressure, etc., according to the experimental requirements and coating characteristics.

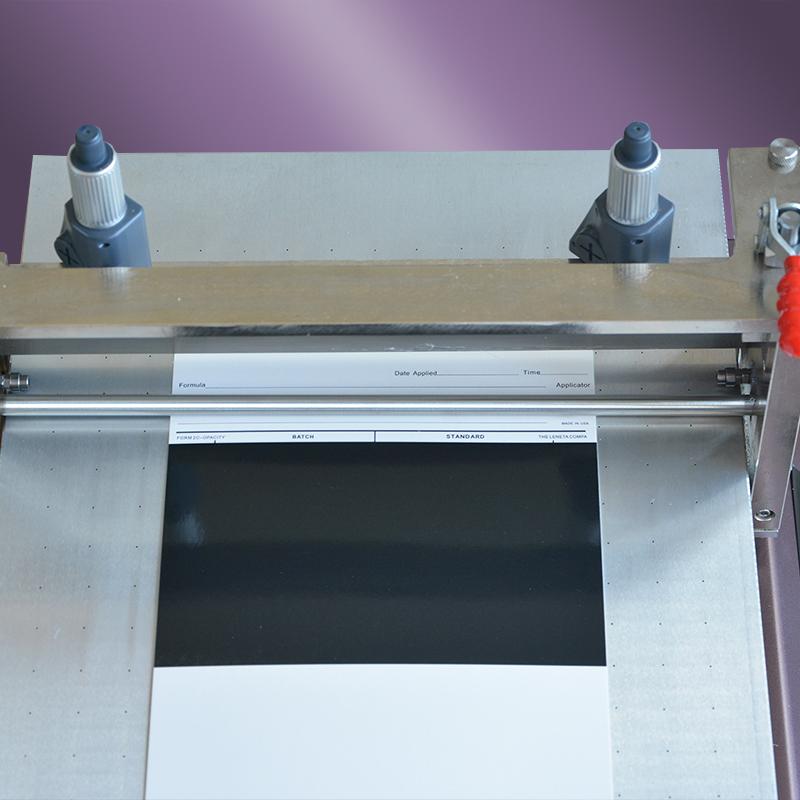

Coating operation: evenly coat the cellulose solution on the substrate. Different coating methods can be selected, such as spin coating method, roller coating method, blade coating method and so on.

Film making: Use auxiliary equipment on the film coating machine, such as a rotary table, pressure-sensitive devices, etc., to fix the substrate at a specific position, and apply a certain pressure and angle to form a cellulose film with a certain thickness of the coating.

Drying: Dry the coated sample at an appropriate temperature and time to fix the coating on the substrate.

Oxidation treatment: The prepared cellulose membrane is oxidized to improve its mechanical properties and stability.

The application of the film coating machine can improve the efficiency and accuracy of the film coating operation, and the appropriate film making method can be selected according to different needs. In the preparation of cellulose film, the use of film coating machine can prepare film samples with different thickness and uniformity for applications in different fields. The use of a film coating machine can also improve the uniformity and stability of the film, and improve the mechanical properties and durability of the film.