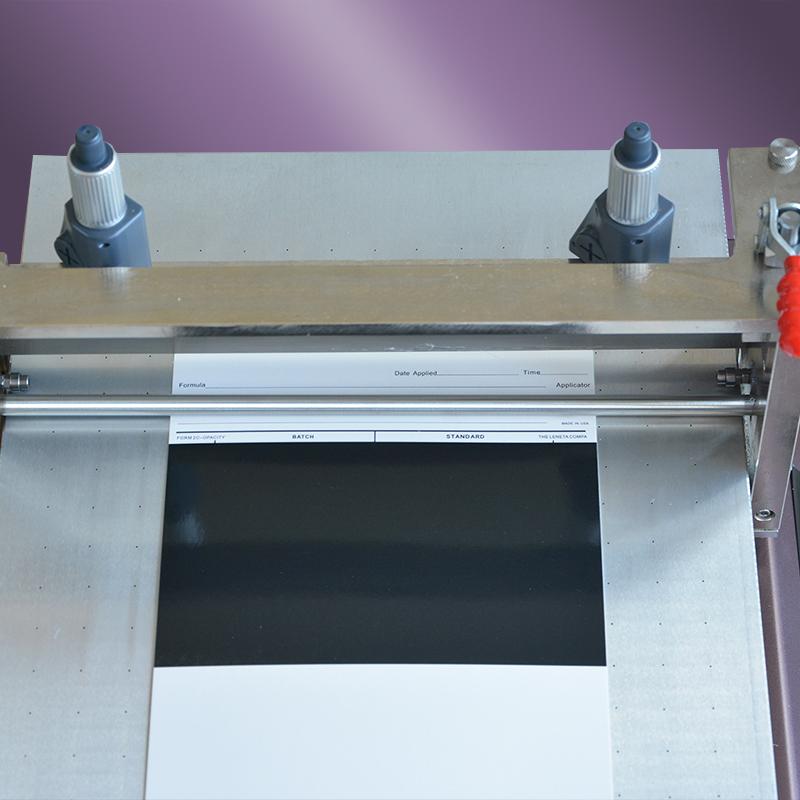

Screen photosensitive glue is a material used to make printing plates, and its coating method is usually realized by a film coating machine. The Film Applicator can control the coating speed and thickness to ensure uniform and consistent coating and provide accurate coating results.

The film coating method is usually divided into two steps: coating and drying. In the coating stage, the screen photoresist is evenly coated on the screen using a Film Applicator, and the uniform coating mode is usually used to ensure uniform coating thickness. In the drying stage, the applied photoresist is dried using the correct temperature and humidity.

The specific film-making method depends on the type and characteristics of the screen photoresist used. Typically, these photoresists need to be exposed to light to form the desired printed pattern. The process of making a screen involves the steps of coating, exposing, washing and drying.

Film applicators help ensure even and consistent coating, which improves print quality and print efficiency.