1 Definition, Purpose and Significance

Gloss is an optical characteristic of the surface of an object. Expressed by its ability to reflect light. The gloss of the paint film refers to the ability of the surface of the paint film to reflect the light irradiated on it in a certain direction, also known as the specular gloss. The gloss of the paint film can be divided into glossy semi-gloss and matt . Glossy coatings—generally refer to those with a gloss above 40, semi-glossy coatings with a gloss between 20 and 40, and matt coatings with a gloss below 10. This is based on the different requirements for the gloss in the actual application of the coating. Divided.

The gloss of the paint film is an important indicator to measure the appearance performance of the paint. Determining the gloss of the paint film is of , especially for some coatings with high decorative requirements such as automotive paints, furniture paints, etc., it can better understand the effect of the paint film on the surface of the coated object. It plays a decorative and protective role.

2 Relevant standards

GB/T 9754_88 Determination of 20°, 60° and 85° specular gloss of paint film without metallic pigments

IS02813:1994 Color depth and varnishes - Determination of 20°, 60° and 85° specular gloss of paint films without metallic pigments

3 Introduction to key points of inspection methods

3.l GB/T 9754-88 Determination of 20°, 60° and 85° specular gloss of paint film without metallic paint

This standard specifies the method for measuring the specular gloss of paint films at geometric angles of 20°, 60° and 85°.

The angle of 60° is suitable for all kinds of paint films. In order to improve the resolution ability, it can be measured at an angle of 20° for high-gloss paint films (when the gloss of 60° is higher than 70 units), and it can be measured at an angle of 85° for low-gloss paint films (60° when the gloss is below 30 units).

3.1.1 Test Principle

The gloss meter uses the principle of photoelectricity to measure the specular reflection light. What it detects is the light opening in a small range of reflection angle. The amount of light increases, and the remaining incident light is absorbed or scattered through the coating surface (the intensity of the absorbed light depends on the color of the coating).

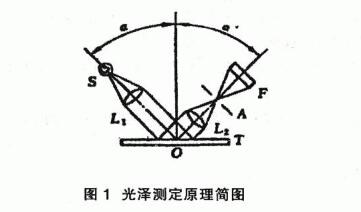

The measurement principle of the gloss meter is shown in Figure 1. The light emitted by the light source S is transformed into parallel light through the lens L1 and projected onto the surface T to be tested at a certain angle a, and the light reflected by T at the same angle is converged by the lens L2. After being absorbed by the photocell F through the field diaphragm A, the photocurrent generated can be read by means of a galvanometer. The luminous flux received by the photocell F depends on the reflection ability of the sample.

3.1.2 Materials and equipment

Glass plate: the area is at least 150mmx100mm, and the thickness is at least 3mn;

Wet film Applicator: specification 100 microns;

Glossmeter: Incidence geometry angle 20°, 60° and 85°.

3.1.3 Operation points

3.1.3.1 Preparation of test panels

Under normal circumstances, use a Wet Film Applicator with a specification of 100 to apply the color paint on a clean glass plate, and dry it under specified conditions to obtain a flat paint film.

3.1.3.2 Gloss measurement

Determination of gloss of paint film on glass substrate: After adjusting and calibrating the instrument, take three readings at different positions of the test paint film parallel to the coating direction, and then calibrate the instrument with a high-gloss working standard push plate to ensure the reading There is no bias. If the result error is less than 5 units, record its average value as the specular gloss value. Otherwise, perform three more measurements, and record the average value and limit value of all six values.

Determination of paint film gloss on non-glass substrates: After adjusting and calibrating the instrument, measure six times in different areas or directions on the surface of the sample, and record the average value and limit value. If the error of the six measurement results is greater than 10 units or greater than 20% of the average value, discard the test panel or record the average value and limit value.

3.1.4 Result presentation

Expressed in units of light and float at a certain angle 6

3.1.5 Precautions

3.1.5.1 When measuring the gloss of varnish, black glass or a glass plate with rough edges coated with matt black paint should be used as the substrate.

3.1.5.2 The preparation method of the paint film will affect the measurement of gloss and luster, attention should be paid to the inspection requirements of the product (especially in the case of spraying).

3.2 Is02813:1994 Paints and varnishes - Determination of 20°, 60° and 85° specular gloss of paint films without metallic pigments

This standard specifies the method for measuring the specular gloss of paint films at geometric angles of 20°, 60° and 85°.

The 60° angle is used for all color paint films. In order to improve the resolution, it can be measured at an angle of 20° for high gloss paint films (at 60° gloss master 70 units), and for low gloss paint films can be measured at an angle of 85° (60° when the light float is below 10 units).

3.2.1 Test principle

Same as 3.1.1.

3.2.2 Materials and instrument settings

Glass plate: the area is at least 150mmx100mm, and the thickness is at least 3mm;

Wet film Applicator: specification 150µm;

Gloss meter: incident geometry angle 20°, 60° and 85°.

3.2.3 Operation points

3.2.3.1 Preparation of test panels

In general, use a Wet Film Applicator with a gauge of 150 µm to coat the paint on a clean glass plate, dry it under specified conditions, and obtain a flat paint film.

3.2.3.2 Gloss measurement

Determination of gloss of paint film on glass substrate: After adjusting and calibrating the instrument, take three readings at different positions of the test paint film parallel to the coating direction, and then calibrate the instrument with a high-gloss working standard plate to ensure that there is no deviation in the readings . If the result error is less than 5 units, record the average value as the specular gloss value. Otherwise, perform three measurements again, and record the average value and limit value of the six values in the gold department.

Determination of paint film gloss on non-glass substrates: After adjusting and calibrating the instrument, test the surface of the sample in two directions at right angles

Measure three times, record the average value and limit value.

Gloss measurement on the surface of the painted test panel: after the instrument is adjusted and calibrated, test the gloss on different parts or directions on the painted surface

Measure six times and record the average value and limit value. If the error of the six measurement results is greater than 10 units or 20% of the large sub-average value, discard the test panel.

3.2,4 Result presentation

Expressed in units of gloss at a certain angle.

3.2.5 Precautions

Same as 3.1.5.