1 Definition, Purpose and Significance

Regarding the scrub resistance of the paint film, it mainly refers to the relative abrasion resistance of the coating when it is often repeatedly scrubbed to remove pollutants during operation. Architectural coatings in work and living places, especially near doors and windows, are often easily stained, which requires frequent scrubbing, so scrub resistance has become a very important assessment index for these paints.

2 Relevant standards

GBIT9266-88 Scrub resistance of architectural coatings

3 Introduction to key points of inspection methods

3.1 Test Principle

On the scrubbing instrument, use a base brush with a specified load to scrub the paint film back and forth under the condition of continuously dripping detergent, and observe the number of times of washing when the surface of the paint film is just exposed or the coating that has been washed to the specified number of times.

3.2 Instrument introduction

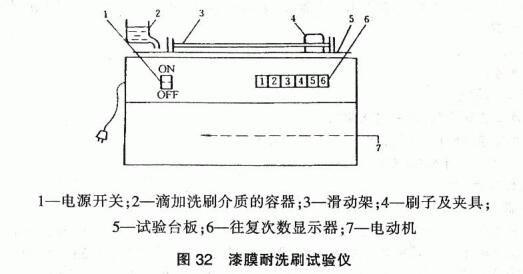

Paint film scrub resistance Tester: as shown in Figure 32, the total weight of the brush and fixture of the instrument is 450g; the reciprocating frequency of the brush is 37 times/min; the moving distance of the brush in each stroke is 300mm, and the movement in the middle 100mm interval is roughly uniform.

Glass plate, cement asbestos board or other agreed materials: 430mmx150mmx3.

3.3 Operation points

Before the test, the bristles should be immersed in water at about 20°C to a depth of 12 mm for 30 minutes, then vigorously shake off the water, and then immersed in a washing medium (0.5% detergent solution, pH 9.5~10.0) to a depth of 12 mm for 20 minutes. Treated brushes can only be used. Fix the model, place the brush on it, rub the coating film back and forth, and drop the scrubbing medium at the same time (the speed is about 0.04g per second), until the specified number of times or until the 100mm area in the middle of the model exposes the substrate. Remove the sample plate and wash it with tap water.

3.4 Result presentation

It is expressed by the number of times of washing when the sample is just exposed, or after washing to the specified number of times, if the coating film of at least two of the three test panels is not damaged, it is considered that the washing resistance is qualified.

3.5 Precautions

3.5.1 The brush should be treated before the test.

3.5.2 When the bristle length is less than 16mm, it should not be used.

3.5.3 The load on the test plate should meet the requirements.

3.5.4 If the bottom material is exposed after the two ends of the sample are rubbed, it will not be considered when judging the result.