Furniture board is a commonly used material for making furniture, and the measurement of its surface gloss is very important. Measuring gloss ensures a smooth, uniform, and highly reflective surface on furniture panels, enhancing their appearance and quality. The gloss measurement of furniture boards can be realized by the intensity of reflected light, and its unit is GU (Gloss Units). Before measurement, it is necessary to ensure that the test environment is not disturbed by external light sources, and an appropriate measurement angle and light source should be used. By measuring the glossiness of furniture panels, its surface quality can be evaluated, and appropriate measures can be taken to improve its surface quality and increase its market competitiveness when necessary.

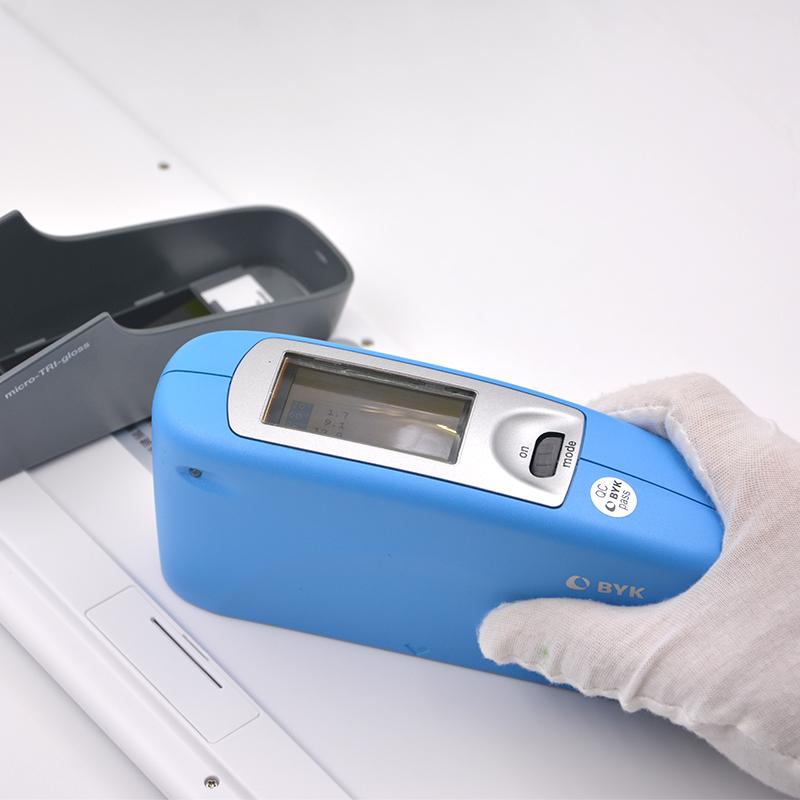

Gloss meter is an instrument specially used to measure the surface gloss of materials, and is widely used in industries such as furniture panels.

The following are the application and measurement steps of the gloss meter in the gloss detection of furniture panels:

application

Detection and control of the surface gloss of the board during the furniture manufacturing process;

Evaluation and classification of panel surface gloss during furniture quality inspection;

Detection and evaluation of surface gloss during furniture maintenance.

Measurement steps

Preparation: place the furniture board on a flat table to ensure that the surface is clean and free of impurities to avoid interfering with the test results;

Adjust the instrument: adjust according to the manual of the gloss meter to ensure that the instrument meets the test requirements;

Measurement: Place the test head of the gloss meter on the surface of the board, and start the instrument for measurement. Generally, multiple tests are required to take the average value to avoid errors;

Record the results: Record the measurement results, evaluate and classify according to the relevant standards of the furniture industry.

North and South Chao reminds you: the gloss meter needs to avoid the influence of direct sunlight, dust interference and other interference factors during the measurement process to ensure the accuracy of the test results.