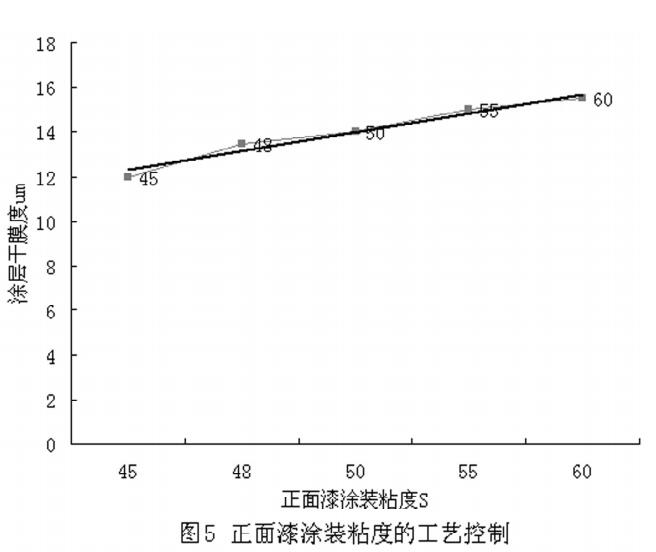

As is well known in the color-coated board industry, in addition to the substrate, the paint constitutes nearly 70% of the color-coated board! Controlling the thickness of the coating film of the color-coated board can greatly reduce the cost. Mr. Zhu Yiwu, a scholar from Fujian Mingguang, wrote "Control of Color Plate Coating Film Thickness Process": the color coated plate proves that the coating thickness is ≥ 20um, if the back is one layer, the coating film thickness is ≥ 5um, if it is two Layer, then ≥12um. This is an international practice. In general enterprises, the thickness of the front coating is generally between 13-17um, and the thickness of the two layers on the back is between 10-14um. The initial coating is between 4-6um.

The author uses Tu 4 cups, wet film meter, micrometer and temperature measuring paper to find out the factors that affect the dry film thickness of the coating (recommended instrument: dry Film Thickness Gauge) through the adjustment and research of various parameters between coatings. The law of change. Thereby reducing production costs while improving the quality of color-coated panels.

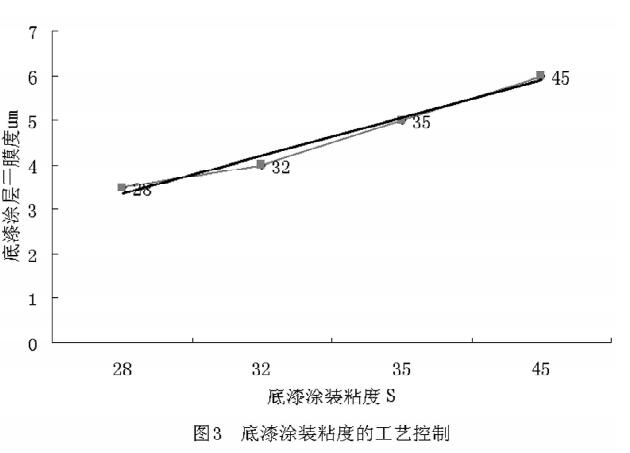

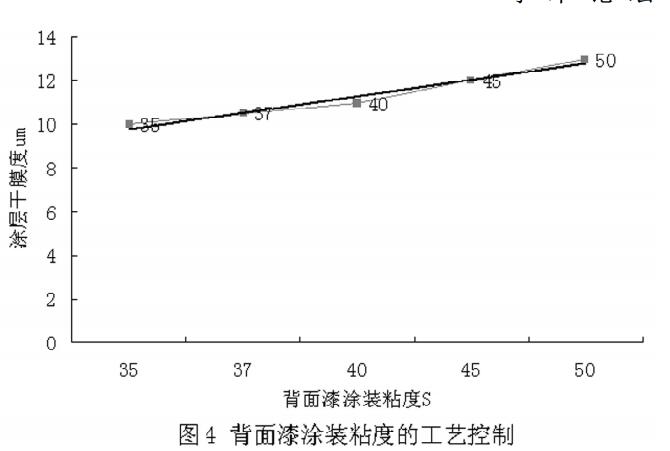

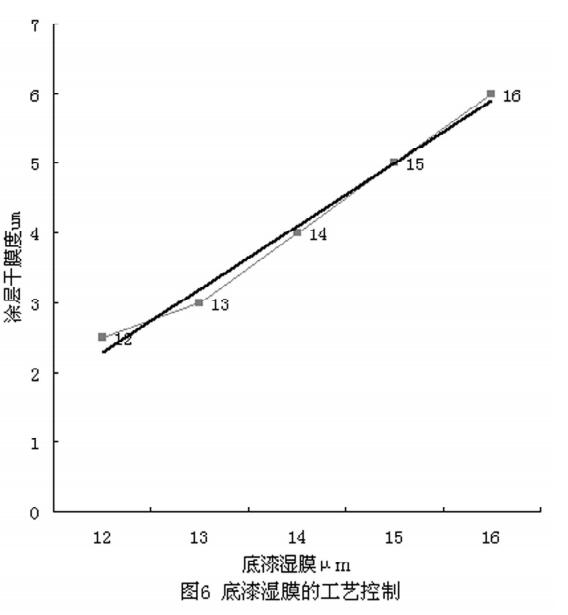

The results of its research show that the main factors affecting the thickness of the coating film of the color-coated board are that the speed ratio of each roller, the coating viscosity, and the wet film thickness are all proportional to the dry film thickness of the coating. The greater the roller speed ratio, the thicker the dry film thickness of the coating; the greater the viscosity of the coating, the thicker the dry film thickness of the coating; the thicker the wet film thickness, the thicker the dry film thickness of the coating.