1. Physical drying

①Volatilization of solvent-based dispersion medium to form a film: it is dried and formed by solvent volatilization and molecular chain entanglement in the coating. One-component coatings such as perchlorethylene paint, lacquer and acrylic paint.

②Coagulation of polymer particles to form a film: it is dried and broken by the volatilization of the dispersion medium and the cohesion of high polymer particles. such as latex paint

2. Chemical drying

Chemical drying means that there are various chemical reactions in the coating film during the flat operation process, the film-forming mechanism is different, and the required film-forming conditions and film-forming processes are also different. There are two main types of chemical drying: normal temperature curing film formation and heating curing film formation.

①Cure and form film at room temperature

Under normal temperature conditions, the coating film is formed by the reaction of its main film-forming substance with oxygen or hydrogen gas in the air or with an intermediate agent to form a high molecular polymer or polycondensate. For example, the dry film-forming of drunken acid paint is the reaction of alkyd resin content with the oxygen in the air; the dry film-forming of lake-blued polyurethane paint is the chemical reaction between the main film-forming substance and the water vapor in the air. ; The drying and film formation of two-component coatings such as epoxy and polyester is the chemical reaction between the main agent and the curing agent.

②Heating and curing film formation. Heating and curing film formation requires the use of heating and baking and other film forming processes. Appropriate process conditions, such as temperature and time, can be selected according to the nature of the coating and the condition of the object to be coated. Commonly used processes for heating and curing include steam, electricity, and far-infrared heating. (Related instrument: oven)

3. The drying time of the paint is the same as that of the appropriate coating

When each coating is applied, it needs a certain interval of painting interval. The interval of painting is not only related to the type of paint, but also related to the temperature, humidity and other conditions during construction. Generally, the next coat is applied after the previous coat is actually applied. The painting interval can be appropriately extended in winter and shortened in summer.

A good coating interval refers to a more suitable coating interval when the proper performance of the coating film is achieved. The determination of the good coating time interval should be considered according to the specific conditions of the coating type and the construction site. In order to achieve a good coating effect, it should be constructed in a good coating interval as much as possible. The drying time and coating interval of commonly used paints are shown in the table below (related instruments: drying time Tester)

4. Supporting design of coating

1. The supporting design of the coating is to select more suitable coating materials and coating systems according to the construction requirements, so as to ensure the implementation of suitable coating matching system engineering.

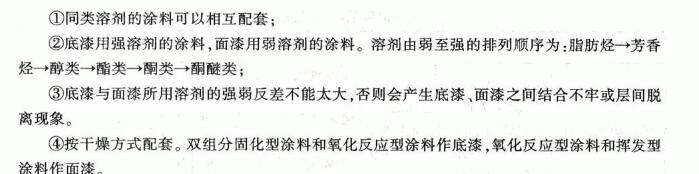

2. The compatibility of coatings refers to the adaptability between the coating substrate and coatings and the varieties of coatings of each layer. The matching of coatings should pay attention to the following four aspects:

① Matching between paint and substrate (coated object);

② Matching of coating types between each coating;

③Supporting between coatings and construction methods;

④Coordination between paint and auxiliary materials.

3. Supporting principles