The protective electrophoretic coating film of the electroplating layer is transparent and retains the original color of the electroplating layer (relevant instrument: gloss meter). And decorative electrophoresis is to electrophoresis a layer of required color coating film on the metal bottom layer or some kind of electroplating layer. The film can be transparent (using dyes) or opaque (using pigments).

At present, gold electrophoretic coating and black electrophoretic coating are commonly used in surface decorative electrophoretic coating. Followed by gun color, antique copper color, blue, red and other colors, there are also two or more than two kinds of color electrophoresis.

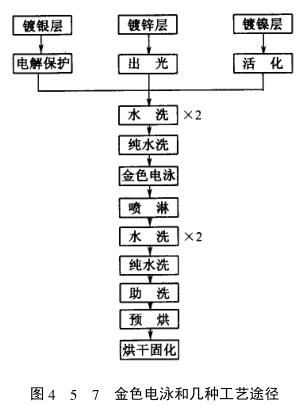

1. Gold electrophoretic coating

It is to mix a red dye and a yellow dye paste in the electrophoretic paint in a certain proportion, and evenly disperse in the electrophoretic liquid with the paint, and deposit on the object to be coated during the painting process. After drying and curing, it forms a dazzling golden color with a strong metallic feel, which is very similar to real gold, almost to the point of being fake. Its color can be achieved by adjusting the ratio of red and yellow, and various K gold can be adjusted. Several technological approaches of gold electrophoresis are shown in the figure.

The electrophoretic coating can be carried out immediately after the parts are electroplated. If the electroplated parts are placed for a period of time after being dried, cathodic electrolytic degreasing is required, and the electrophoretic coating can only be carried out after activation treatment.

Gold electrophoresis on steel parts generally has the following three methods: the electrophoresis coating film after silver plating (flash silver plating) resembles real gold; the electrophoresis coating film on the galvanized layer is dark; Darker, titanium nitride-like color.

2. Black electrophoretic coating

Black pigment paste is often used in black electrophoretic coating, which can be divided into bright, semi-bright and matte electrophoretic coating films, and acrylic and epoxy resin electrophoretic coatings are mostly used. The former is mostly used for surface decoration, and it was mostly used for primer. There are also many units that use epoxy resin as a topcoat, and the effect is also very good.

Process flow of black electrophoretic coating (taking steel parts as an example):

Chemical degreasing→Water washing→Electrolytic degreasing→Hot water washing→Water washing→Water washing→Activation→Water washing→Water washing→Normal temperature phosphating→Water washing→Water washing→Pure water washing→Black electrophoresis→Spray→Water washing→Water washing→Pure water washing→Building→ Pre-baking → drying and curing

3. Matt color (delustering) electrophoretic coating

In addition to functional needs (such as camera devices), matte coating films are currently popular in the market for decorative dumb color electrophoretic coatings. The matte coating film can be obtained by the following processes:

(1) The object to be coated is professionally sandblasted;

(2) The object to be coated is first plated with matte nickel (sand nickel or forged nickel);

(3) The object to be coated is first plated with dumb copper, and then plated with dark nickel;

(4) Add matting agent to the paint.

If it is used for transparent protection, three methods (1) (2) (3) are generally used, especially (1)/(2)

Method; if it is opaque and matte, the method (4) is generally used to obtain an electrophoretic coating film with a matting effect.