There are many construction methods of architectural coatings, and the construction methods and construction tools should be correctly selected according to the specific conditions of the product, so as to achieve a good number of coating results, generally can be used brushing, spraying, roller coating, plastering, wiping, brushing, paint coating and other methods, which can be used alone or in combination with each other. General latex paint should be brushed, roller or sprayed; The sand wall paint with aggregate can be sprayed or smeared. Multi-layer architectural coatings, such as floating, can be applied in a combination of spraying and pressure coating. Elastomeric brushed coatings can be applied with a special brushing method with holes. Ordinary elastic coatings should be applied in person, and it is easy to form a thicker coating film. According to different construction methods, different construction tools can be selected, and the specific construction tools are as follows.

1. Stir bar

It can be used to stir the paint to make it uniform and improve the flow state of the paint. (Related Instruments: Stirrer)

2. Sentence tray

The width of the metal or plastic square disc is subject to the simple capacity of the roller, ranging from 180~350mm; Its use is mainly for roller coating to contain the paint for the roller to be simple, and it is required to make the roller evenly covered with paint.

3. Paint filter screen

The paint filter is used to get rid of dirt or paint in the material. The sieve should be effectively cleaned immediately after use, so as not to block the screen, or nylon cloth or fine gauze can be directly laid on the phase mouth for lacquer.

4. Grinding blocks

This tool is used to hold the sandpaper so that it remains flat for easy sanding. (Grinder)

5. Empty paint buckets

During construction, empty barrels are required for the preparation of coatings, transitions, dilution, etc., which are convenient for construction.

6. Paint brush

When the paint construction adopts the manual brushing process, the paint brush is generally used. Brushing is an ancient and commonly used construction method, and the advantages of this construction method are that it saves paint, is easy to apply, and has a wide range of applications. The disadvantage is that the construction efficiency is low, easy to leave brush marks, uneven thickness of the coating film, affect the smoothness and beauty of the coating film, according to different construction objects, you can choose different sizes, different shapes of paint brushes, paint brushes generally have wool brushes, row brushes, etc. There are many kinds of bristle materials, and soft wool brushes are mainly used in the construction of general wall architectural coatings. The selection of paint brush generally requires that the front end of the paint brush is neat, soft to the touch, no broken hair and inverted hair, and a good paint brush that does not lose hair when used. After the construction is completed, wash the brushes with water or solvent, spin or dry and store in a dry place. See Figure 3-7 for paint brushing.

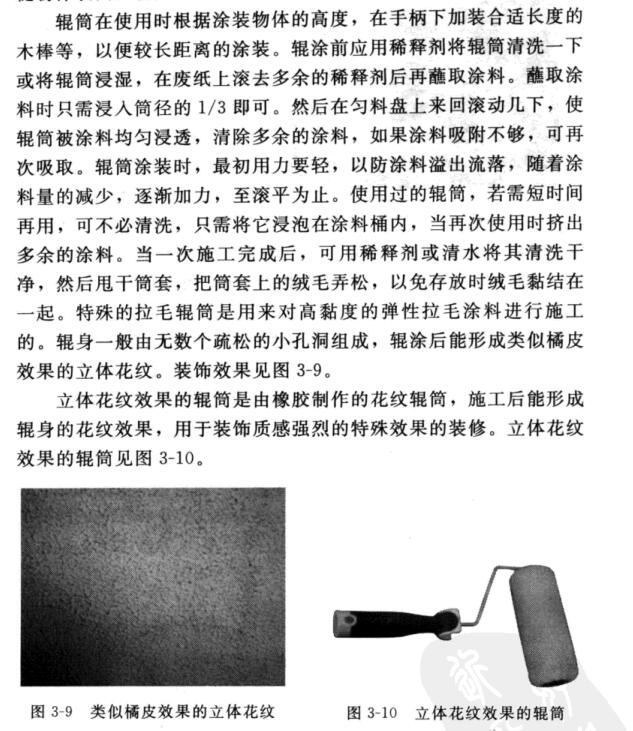

7. Rollers

The main tools of roller coating construction are roller and uniform tray, roller coating saves time and effort, easy to operate, high efficiency, and the final decorative effect and the quality of the simple has a great American system, - Be sure to choose a suitable, good Jane, the Jane is a hollow round Jane with a small diameter, the surface layer is glued to the wool or synthetic fiber made of plush, the Jane is composed of a light frame and a visual sleeve, and the roller sleeve can be loaded and unloaded freely. There are many types and specifications of roller slips, and the selection should be adapted to the condition of the finish and the type of coating, mainly from the width of the visibility, the fluff length of the sleeve and the material of the simple sleeve. The width of the visual simplicity is generally 11~23cm, and the standard diameter is 4cm. The small width of the roller can be used to paint the door frame, skirting board, etc., the fluff length of the sleeve is generally 4.5~40mm, there are short, medium and long three specifications, which have a certain impact on the performance of the roller. Short city hair absorbs less paint, and the resulting texture is also fine and shallow, which can be rolled on smooth surfaces. There are many coatings for medium and long fluff sucking, which can be used on the surface of ordinary objects and rough objects, and the roller is shown in Figure 3-8.

8. Spray guns

Spraying construction is a coating method that uses the Spray Gun as a construction tool, and sprays the paint from the nozzle of the Spray Gun by compressed air or other means as the power, and forms a uniform coating film by dispersing and depositing in the form of a mist, with high spraying efficiency and suitable for large-area coating projects.

Gaps, small holes and tilts, curves, concave and convex and other shapes of objects can be constructed, and beautiful, smooth, smooth high-quality coating film can be obtained, the Spray Gun is shown in Figure 3-11.

There are two types of coating methods for general architectural coatings: air spraying method and high-pressure airless coating method.

(1) Air spraying method The main tool is the Spray Gun, which is usually composed of the gun body, air nozzle, paint nozzle, regulating valve, trigger, paint building, handle, air joint and other components, which is used for the construction of various coatings.

There are many types of Spray Guns, according to the type of paint and the requirements of the coating object, according to the caliber of the nozzle and the amount of air used to reasonably choose different models and types of Spray Guns. The larger the diameter of the nozzle, the greater the pressure, and the greater the amount of paint ejected; The higher the viscosity of the coating, the less the amount of paint is sprayed, and the distance between the Spray Gun and the surface of the coated object has a greater impact on the quality of the coating film. The distance is too far, the coating film becomes thinner, the paint loss is large, the coating film is easy to fall off, the coating film is uneven, and the gloss is greatly reduced when it is serious, - The general spray distance is 200~500mm, and the spraying pressure can be adjusted according to the size of the nozzle and the nature of the coating, The compressed air leads from the pipe to the nozzle, at this time the paint flows out of the nozzle, blows the paint back onto the object, adjusts the auxiliary air passage on the side of the nozzle and the different positions of the nozzle, and the paint flow of different shapes can be obtained, after the spraying is completed. Turn off the switch of the compressed air pipe, pour the excess recyclable paint back into the original paint phase, and then clean the Spray Gun to dry the sea, and no paint can remain in the Spray Gun. When cleaning the Spray Gun, the corresponding thinner of the paint can be poured into the paint building, open the air duct, shout out the cleaning liquid, and clean the gun, the quality of the spraying construction is mainly determined by the viscosity of the coating, the working pressure, the distance between the nozzle and the surface, and the technical enthusiasm of the operator, in order to obtain a smooth, flat and uniform coating, you need to learn the correct operation method when spraying, first adjust the paint to the appropriate construction viscosity, keep the Spray Gun mouth perpendicular to the object surface when spraying, and move the Spray Gun at a uniform speed and in parallel. And the edge of each spraying amplitude, should be repeated on the previous sprayed amplitude edge image L/3~L/2, and the width of the lap should be consistent, if the width of the lap is changeable, the film thickness will be uneven, may produce stripes or marks, or the phenomenon of flowers, (2) high-pressure airless shouting coating makes the paint be pressurized through the pressurized pump, through the special cemented carbide nozzle spray, its rate is very high. When the high-pressure paint flow leaves the nozzle and reaches the atmosphere, with the impact air and the rapid cutting of the high pressure drops, the solvent in the paint swells violently and disperses l atomization, and is coated on the surface of the coated object at high speed. The production efficiency of high-pressure airless coating can be increased by several times to more than ten times compared with general spraying; The paint mist of spraying is less than that of air spraying, and the utilization rate of paint is improved, which can save paint and solvent, reduce the pollution of process fog, and improve labor conditions. It can realize the spraying of high-solids and high-viscosity coatings, and form a thicker coating film at one time; Reduce the number of construction times and shorten the construction period; It eliminates the defects of the coating film caused by the compressed air containing impurities such as moisture, oil, dust, etc., and the adhesion of the coating film is good, and a good coating film can be formed even in the whole gap and edges.

The disadvantage of high-pressure airless spraying is that the amplitude of the spray and the amount of spray can not be adjusted during operation, and the nozzle needs to be replaced to achieve the purpose of adjustment, which is not suitable for thin layer of decorative coating, and the rate of painting is very high, and certain protective measures are required.

The equipment of high-pressure airless spraying mainly includes pressurized pumps and Spray Guns, in addition to pressure accumulators, paint transitions, high-pressure hoses, etc., and the more critical equipment is Spray Guns. Spray inspection is the main tool of high-pressure airless spraying, which is composed of gun body, nozzle, transition net and connecting parts. It is required to be able to withstand the high pressure of 50MPa, the action of various chemical media, and have good sealing and wear resistance, and do not leak high-pressure coatings; The bolt should be flexible, and shouting or cutting off the paint flow can be completed instantaneously; It is equipped with a full safety device, and after the safety device is locked, pull the trigger of the Spray Gun, and the Spray Gun should not be opened.

When using high-pressure airless spraying, the following should be noted.

(1) Spraying pressure and flow, for a certain type of airless spraying equipment, when the viscosity of the paint used remains unchanged and the pressure of the input compressed air is constant, the relationship between the shouting pressure and the flow rate is: the flow rate increases, the spraying pressure decreases, and when the pressure of the output compressed air increases, the spraying pressure and the flow rate increase accordingly.

(2) Paint viscosity and spraying pressure, different types of paint viscosity is different, and the viscosity of high solids paint is especially large. (Related instruments: viscometer) the higher the viscosity, the greater the spraying pressure required during construction, the construction instructions of various coatings indicate the viscosity of the coating and the pressure ratio required for airless spraying construction, the pressure ratio of general low-viscosity coatings is 23 l, 32 1, and the construction pressure ratio of high-solids coatings is generally about 45 1. However, the pressure of spraying should not be increased blindly, because with the increase of pressure force, the wear of the nozzle is gradually accelerated, and the large-diameter nozzle should be replaced.

(3) Before high-pressure airless spraying, according to the paint used and the object of spraying, a nozzle with a certain aperture and shape should be selected. The aperture of the nozzle determines the size of the flow rate, and the shape of the nozzle determines the amplitude of the spray.

(4) When high-pressure airless spraying, the spray angle of the jet stream is 30'~8o°, the amplitude of the jet is 8-75cm wide, and the selected jet amplitude is 3o~40cm when shouting the large plane; The painted object is large. For a large amount of painting on the convex surface, use 20~30cm first; Spraying general small objects, choose 15~25cm, when the required atomization effect can be obtained, the use of the lowest spraying pressure, can prolong the service life of the nozzle, (5) to ensure that there is enough sealing liquid in the poly oil cup to maintain the sealing and slippery performance of the plunger, in the air motor should often add a certain amount of lubricating oil, in order to ensure the normal mechanical properties of the motor.

(6) When spraying with high pressure airless, the gun is perpendicular to the surface of the sprayed object, 3o~ 4ocm from the surface. The Spray Gun should move evenly at a suitable rate and parallel to the surface of the workpiece to avoid sagging and uneven coating. The distance and vertical angle between the Spray Gun and the object surface are controlled by the body, and the movement of the Spray Gun should also use the body to assist in the movement of the arm, not to move the hand, but the wrist should be flexible.

(7) After the spraying is completed, the excess paint should be poured back into the original paint barrel, and then the Spray Gun should be cleaned, and the paint residue in the Spray Gun is not allowed, and the diluent should be sprayed to clean the pipe and the inside of the gun. Then completely relieve the pressure, disassemble the nozzle and sheath one by one, remove the nozzle first, and wipe it clean with solvent. When cleaning, carefully wash the nozzle and gun body with a soft brush with solvent, when the air hole is blocked, you need to dredge it with a cork needle, and do not use a hard tool to remove the debris in the nozzle.