application background

Wire and cable are an important part of power transmission and distribution, and their performance and stability are affected by the ambient temperature. During the production, transportation and use of wires and cables, they may be affected by different ambient temperatures such as high temperature and low temperature. Therefore, high-low temperature resistance tests are required to test the electrical and mechanical properties of wires and cables at different temperatures. High temperature may cause aging of wire and cable insulation, deformation or melting of conductors, and low temperature may cause the plastic material of wire and cable to become brittle, resulting in breakage or leakage. Through high-low temperature resistance tests, the durability and quality of wires and cables under different environmental conditions can be verified, ensuring that wires and cables can maintain stable performance and long service life under various environmental conditions, thereby improving their reliability and safety . The high-low Temperature Test Chamber can simulate high temperature and low temperature environments, and test and evaluate the physical properties, electrical properties, heat resistance, cold resistance and other performance indicators of wires and cables.

experiment procedure

The steps of high-low temperature resistance test of wire and cable are as follows:

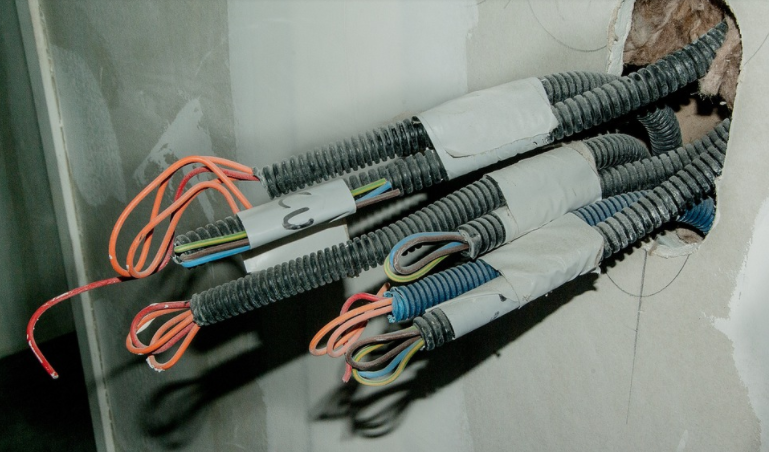

Prepare test samples: select wire and cable samples that meet the standards, as close as possible to the actual use state.

Put the sample in the high-low Temperature Test Chamber: set high or low temperature conditions according to the test requirements, and put the sample in the high-low Temperature Test Chamber.

Maintain temperature stability: Wait for the high-low Temperature Test Chamber to reach the set test temperature and maintain a stable state, which generally takes several hours to several days.

Test sample performance: Expose wire and cable samples to high or low temperature environment for a period of time in a high-low Temperature Test Chamber, and then test their physical properties, electrical properties, heat resistance, cold resistance and other indicators.

Observe and record: Observe the changes of the test samples and record the test results.

Repeat test: Repeat the above test steps according to the required test times.

Result analysis: analyze according to the test results to evaluate whether the high-low temperature resistance performance of the wire and cable meets the standard.

Precautions

Before the test, check whether the high-low Temperature Test Chamber meets the standard requirements.

Testing should be carried out in accordance with relevant standards and testing requirements.

The stability of the test environment should be maintained during the test.

After the test, the high-low Temperature Test Chamber should be cleaned in time to avoid affecting the results of the next test.