The softness (toughness) of the coating refers to the performance of the coating on the surface of the coated product that causes damage under deformation conditions. According to the requirements of the standard, the minimum point that the bending surface of the sample on a mandrel with different diameters does not cause damage to the coating is used. The shaft diameter is used to indicate the softness of the coating, so the test results actually reflect the comprehensive performance indicators such as the tensile strength, anti-expansion strength, and adhesion of the coating to the substrate. The mandrel bending method is generally only suitable for the determination of the softness of paint films.

1. Specifications of test instruments and mandrels

The softness Tester for measuring the softness of the coating is composed of 6 mandrels with different groups and thicknesses. They are fixed on the base, and the base can be fixed on the edge of the test bench with screws. The specifications of the 6 mandrels are as follows:

Mandrel 1 10mm diameter and 15mm outer diameter casing

Mandrel 2 Cutting surface 5mmx10mm, radius of curvature 2.5mm

Mandrel 3 cut surface 4mmx10mrn, radius of curvature is 2 mm

Mandrel 4 section 3mmx10mm. The radius of curvature is 1.5mm

Mandrel 5 Cutting surface 2mmx1o mm, radius of curvature 1mm

Mandrel 6 Cutting surface 1 mmx10 mm, radius of curvature is o.5mm

The length of each mandrel is 35 mm.

2. Test steps

(1) Sample preparation According to the requirements of the standard, use a tin plate (or follow the product standard)

Material) with the same process and conditions as the actual production, prepare a paint film on its surface, cut into 25mmx120mmx0.2~0.3mm samples after drying and set aside.

(2) Softness test Put the sample under constant temperature and constant humidity conditions (relevant instrument: constant temperature and humidity Test Chamber), with the paint film facing up, press the test piece tightly on the mandrel of the softness Tester with both hands to make it Bending around the shaft, after bending, use the thumbs of both hands to be symmetrical to the center line of the mandrel, and the whole operation should be completed within 2-3 s. Usually, the test should be carried out gradually from the mandrel of the group to the thin mandrel one by one until the sample is broken. If a mandrel of a certain diameter is specified in the product standard, it can be directly measured with the mandrel of this specification.

(3) Result evaluation Take down the sample after the test and carefully observe it with a 4x magnifying glass to check whether the paint film has any damage such as mesh number, cracks or neat coating. If one of the mandrels is bent and damaged If there is no phenomenon, the mandrel diameter of the previous bending test can be regarded as the result of multiplying the softness test, or the mandrel specified in the standard can be judged as unqualified.

3. Calculation of coating elongation

When the coating is bent on mandrels of different diameters, it is actually an assessment of the extensibility of the coating. Usually, the elongation of the legal layer is calculated based on the minimum mandrel diameter that does not cause coating damage during the bending test.

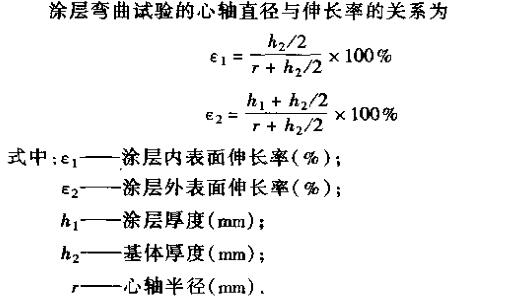

The relationship between the diameter of the mandrel and the elongation of the coating bending test is