1 Types of surface defects and their characteristics

1) Pinhole refers to a type of fine hole on the surface of the coating that is similar to the tip of the needle, although its density and distribution are not the same, but when observed under the magnifying glass, its size and shape are generally similar. For example, the pinhole of the electroplating layer is usually a defect caused by the adsorption of hydrogen bubbles during the electroplating process.

2) Pockmarks refer to a kind of irregular cavities on the surface of the coating, which are characterized by different shapes, sizes and shades. Pockmarks are generally caused by defects in the substrate or adhesion of foreign matter during the plating process.

3) Burr refers to a raised and stinging foreign body on the surface of the coating, which is usually characterized by the plating to the top or in the high current density area.

4) Bubbling refers to a type of raised bubble on the surface of the coating, which is characterized by different sizes, densities, and separation from the matrix. Bubbling is generally more obvious on the coating of zinc alloy and aluminum alloy.

5) Peeling refers to cracked or non-cracked defects in which the coating peels off from the substrate (or base coat). Peeling is usually a malaise caused by poor pre-treatment.

6) Spots refer to a type of defects such as color spots and dark spots on the surface of the coating. It is caused by poor deposition during the electroplating process, adhesion of foreign matter or improper cleaning of the passivation solution.

7) Haze refers to the existence of cloud-like coverings of different degrees on the surface of the coating, most of which are produced on the surface of the bright coating.

8) Yin and Yang surface refers to the defects of local brightness or uneven color on the surface of the coating, which in most cases show a certain regularity in similar products.

In addition to the above-mentioned surface defects, the coating surface sometimes has silk flow, abrasions, water traces, as well as tree technology, sponge coating and other defects, which should be strictly inspected.

2. Test conditions

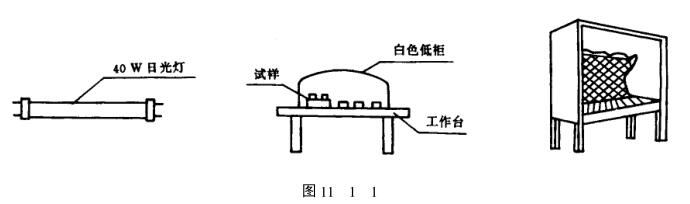

In order to clearly observe the coating surface defects and prevent the interference of external factors, the daily inspection of coating surface defects should be carried out on the specified appearance inspection workbench or appearance inspection box (as shown in Figure 11 _ 1 _ 1)

When natural lighting is used for visual inspection, the specimen should be placed on a white platform with no reflected light and inspected under natural scattered light in the same direction.

When the exterior inspection workbench and the exterior inspection box are artificially illuminated, the illumination should be 300lx approximate natural light (equivalent to the illuminance at 500mm of the 40W fluorescent lamp), and a white typewriting paper cabinet should be placed under the lighting for daily measurement.

During daily inspection, the distance between the sample and the naked eye is not less than 300mm, and for important coatings and coatings with special requirements, 2~5 times magnifying glass inspection is allowed.

3. Test Method

For the coating for coating appearance defect inspection, a clear soft cloth or phase yarn should be used to remove the oil stain on the surface of the sample before inspection, but care should be taken not to scratch the coating.

During the inspection, the operator should concentrate on carefully observing whether there are various impermissible defects on the surface of the coating, and make a correct assessment according to the quality and technical standards of the product. The degree of malpractice should be explained in words, and if necessary, the appearance should be sealed.

Under normal circumstances, the coating on the surface of the coated product should meet the requirements of fineness, uniformity, completeness and smoothness. In the parts specified in the product, the following surface defects are not allowed:

(1) Obvious stomata, bubbles, flow and wrinkling;

(2) There are pittings, ash slag, dirt and obvious unevenness of the coating film on the main surface;

(3) There are serious defects such as leakage, peeling, wear and stickiness; (Related Instruments: Adhesion Meter)

(4) For the surface of the product with color and gloss requirements, there is color difference and uneven gloss. (Related Instruments: Colorimeter)