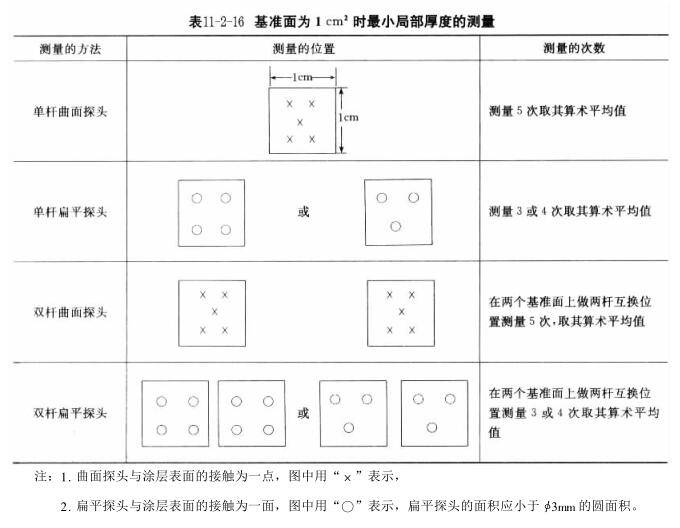

The magnetic measurement method is a method of measuring the thickness of a non-magnetic coating on a magnetic substrate by using electromagnetic principles. This method is suitable for measuring the thickness of a non-magnetic coating or a chemical protective layer on a sub-magnetic substrate. At present, there are many kinds of magnetic Thickness Gauges in CHINA, such as cH_1, DHc_1 and Qcc_A. Before the measurement, the instrument should be systematically adjusted on the standard sample to ensure its measurement accuracy. It can also be used on uncoated substrates. At this time, the standard and the non-coated substrate should be compared at zero, and the thickness difference is called the correction value. Both the supplier and the buyer unify the sample and method to determine the correction value. Some of the conventions described above are carried out. When the reference plane is 1cm2, the measurement of the minimum local thickness is shown in Table 11_2_6

When the datum is 1dm2, no matter what type of instrument and what kind of probe is used for measurement, the 10-point method shown in Figure 11_2_7 should be used to measure 10 times on the datum, and the arithmetic mean value should be taken.

Factors affecting the measured value:

(1) The influence of some factors of the coating itself, such as thickness, conductivity and surface roughness, etc.,

(2) The influence of certain factors of the base metal itself, such as thickness, magnetism, curvature, surface roughness, machining direction and residual magnetism, etc.;

(3) The influence of external factors, such as the surrounding magnetic field and external attachments, etc.

(4) The influence of measurement techniques, such as probe pressure, probe orientation and edge effects, etc.

The influence of the above factors should be excluded and corrected according to the provisions of GB4956.