Atmospheric exposure test is to carry out the actual corrosion test on various electroplated or other surface treated samples on the sample holder (outdoor or indoor) under natural atmospheric conditions, through regular observation and measurement of the corrosion process characteristics and corrosion rate Determine its protection life. Atmospheric exposure test is an important method to correctly judge the corrosion resistance of coatings or other protective layers, and its evaluation results are usually used as the basis for formulating coating thickness standards.

1. Sample requirements and exposure methods

For the sample used in the atmospheric exposure test, the steel plate (or other metal plate) with a sheet-like sample size of 50mmx100mmx1~2mm is used as the substrate. The size of the physical sample is not limited, but it should be placed with the main surface up and facing south.

Each sample should have a number that is not easy to disappear, such as stamped with a steel stamp or a plastic plate with lettering.

The exposure methods of samples or objects generally have the following requirements.

(1) Samples can be exposed all year round, but when the same batch of samples is exposed in different regions, the testing time should be consistent.

(2) Before the test starts, the sample number, coating structure, thickness, appearance gloss, etc. shall be recorded on a special test record card. And write the test outline (including: test purpose, test requirements, inspection cycle, etc.). One to three samples of each type should be kept in a desiccator for comparative observation during the test. (Related Instruments: Drying Time)

(3) After the sample starts to be exposed, the inspection frequency should be frequent within the first 3 months, usually 2-3 times per month. During the inspection, attention should be paid to the time when corrosion spots begin to appear, and detailed records should be made. Check monthly after 3 months and every 3 months after one year.

(4) If it snows on the outdoor exposed samples in winter (referring to areas with snow in winter), the snow on the surface should be wiped off regularly.

(5) When taking the sample, it is not possible to directly contact the main surface with the hand (the edge of the sheet sample can be taken, and the non-main surface of the sample with irregular shape can only be taken). It is not allowed to contact or rub the two pieces of samples to prevent man-made mechanical damage or electrochemical corrosion, which will cause errors in test results.

2. Qualitative evaluation of test results

After the coating is exposed to the atmosphere, the qualitative evaluation of the test results is by visual inspection or magnifying glass (3 to 5 times) observation, and sometimes some simple tools and equipment are also used appropriately.

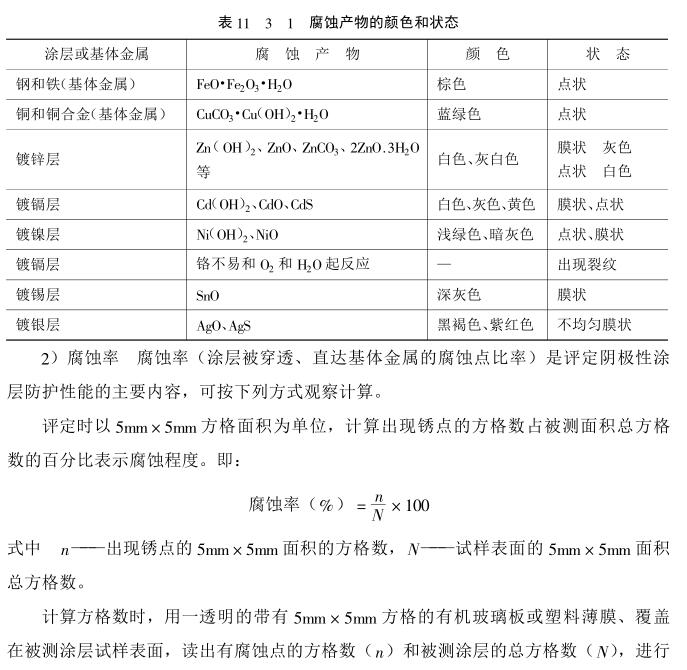

The corrosion products of various coatings under atmospheric corrosion conditions have unique symbols such as color and state. From these characteristics and their development, the corrosion degree of the coating or base metal can be qualitatively judged, thereby determining its protective performance. The qualitative inspection and recording of the coating mainly include the following five aspects.

1) The color and state of coating and base metal products (see Table 11_3_1)

3) Gloss The gloss of the coating after being exposed to the atmosphere (relevant instrument: gloss meter) refers to the degree of oxidation of the coating when it is corroded in the form of a film. When checking and evaluating, it should be compared with the same original sample preserved. According to the degree of gloss loss of the coating, it is divided into:

(1) Good—the gloss has no change or the change is not obvious;

(2) The gloss of Weiyin-1 has changed slightly, but the gloss still remains;

(3) Dull—lost in luster, dark in color.

4) Cracking Coating cracking refers to cracks visible to the naked eye on the surface of the coating after corrosion. The calculation method is the same as calculating the area percentage of corrosion rate.

5) Determining the corrosion level from the qualitative assessment results The coating corrosion level is determined by the qualitative assessment results, which are generally divided into five levels.

Level 1 The coating surface has no change, or only dull luster.

Level 2 The coating has corrosion points or film-like oxides; or the gloss is dull, but there are no base metal corrosion points.

Level 3 Corrosion spots of the base metal appear, but less than 10% of the total area.

Level 4 The base metal corrosion point area is less than 30% of the total area; or the coating crack area reaches the same level.

Level 5: The base metal corrosion point area exceeds 30% of the total area; or the cracking area of the coating reaches the same level.

If the coating reaches level 5, it has been severely corroded, and the test can be terminated.

3. Quantitative evaluation of the results of sample exposure

The quantitative evaluation of coating corrosion mainly uses the weighing method, that is, the weight loss of coating corrosion per unit time is measured, and the corrosion rate is obtained.

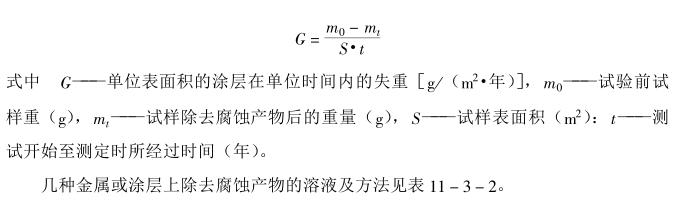

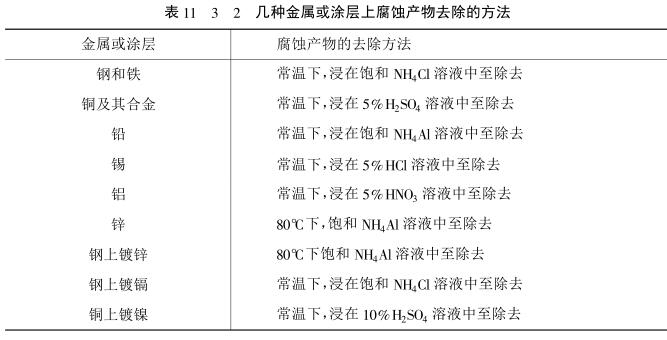

The sample for quantitative evaluation should be weighed accurately before the test, after a period of exposure test, the sample should be taken out, diffused with the specified solution to remove the corrosion products, and then weighed after drying. The two weighing results were used to calculate the corrosion rate according to the following formula: