This method is an improved method of neutral salt spray test. Because it is acidified with acidic acid in sodium chloride solution, and copper chloride is added to improve the corrosion rate and effect on some metals, it has achieved good results that the cathodic coating corrosion mode on the steel substrate is close to the actual environment. Compared with the neutral salt spray, the CASS method not only accelerates the corrosion rate, but also has better reproducibility, so it is gradually replacing the neutral salt spray for the corrosion resistance test of cathodic coatings.

This method is applicable to the corrosion resistance inspection of cathodic coatings (copper, nickel, chromium, coatings, etc.) on steel substrates or zinc alloy castings and anodic oxide films on aluminum or aluminum alloys.

1. Test equipment

The test equipment for the copper salt accelerated acid salt spray test is roughly the same as the salt spray test equipment, except that the high temperature resistance of the box is required to be higher (50±1°C). At present, in addition to the equipment specially used for the CASS test, there are also general-purpose equipment for the salt spray test.

2. Test solution composition

Sodium chloride (NaCl) 50±5g/L

Copper chloride (CuCl2·H20) 0.2,6±0.02g/L

pH (adjusted with acid) 3.2±0.1 (related instrument: pH meter)

The above solutions were prepared with chemically pure reagents and distilled water, and filtered to remove solid impurities for later use.

3. Test conditions and methods

Except that the test temperature is 50±1°C, the other conditions are the same as those of the salt spray test

The specific test method is carried out with reference to the neutral salt spray test.

4. Evaluation of test results

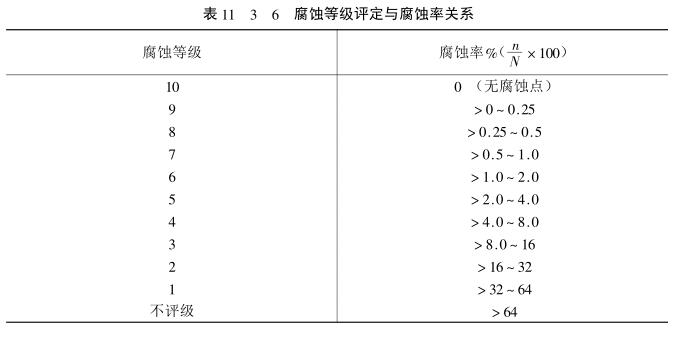

For the evaluation of test results, in addition to referring to the salt spray test method, the corrosion grade can also be evaluated according to the surface corrosion rate of the sample (see the evaluation of the results of the atmospheric exposure corrosion test), see Table 11_3_6.