The periodic infiltration corrosion test (referred to as the periodic immersion test) is a test method that simulates the artificial rapid corrosion of the coating in the semi-industrial marine atmosphere. It is applicable to the corrosion resistance test method of galvanized layer, cadmium plated layer, decorative chrome layer and aluminum alloy anodized film. The results are superior to the neutral salt spray test in terms of acceleration, simulation and reappearance.

1. Test equipment

The test equipment used in the weekly immersion test often adopts the FL_65 wheeled circumferential immersion test machine.

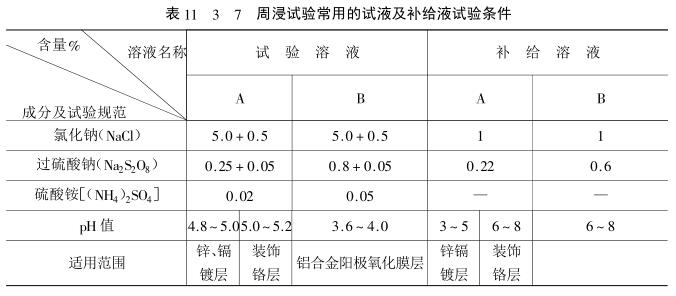

2 Test solution and make-up solution

See Table 11 _ 3 _ 7 for the test solution and supply solution test conditions commonly used in the weekly immersion test.

3. Sample

The size of the sample is generally 60mmx40mm or 100mmx50mm, and sometimes the coated piece can be directly used for the weekly immersion test.

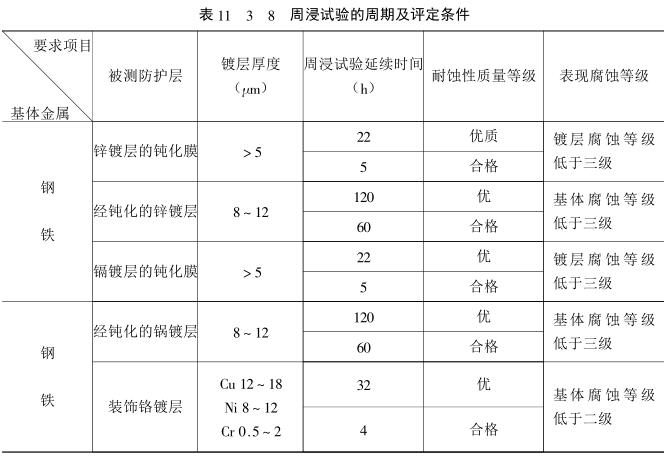

4. Test cycle

See Table 11_3_8 for the cycle and evaluation conditions of the weekly immersion test.

5. Inspection and evaluation of test results

The samples that have undergone the weekly immersion test are generally divided into 8 grades according to the size of the corrosion area on the surface of the coating and the percentage. The percentage of corrosion damage is based on the size and number of corrosion spots on the surface of the sample, and its density and size are evaluated against the standard chart, and then the corrosion grade of the evaluation result is obtained by calculation or table lookup.