There are many methods to detect coating porosity, which can be directly measured according to the physical definition of coating porosity, such as buoyancy method, direct rod measurement method, and later invented chemical methods (filter paper method, paste method, dipping method), electrolytic method, etc. Each method has its own characteristics and uses. This paper mainly introduces the filter paper method.

filter paper method

The filter paper method was once seen in the Japanese standard (JIs H8663-1961) - Test method for aluminum sprayed products, and it is still a common method now, which is summarized as follows.

1) Principle The matrix metal is corroded to produce ions, which pass through the pores and produce characteristic color development on the test paper by the indicator. That is, in order to test the presence of pores that penetrate through the coating to the surface of the substrate, the blue spots of ferrocyanide are traced on the test paper, and the spots are counted to evaluate the porosity of the coating.

This law is applicable to the inspection of single-metal coatings and multi-metal coatings such as copper, nickel, chromium, tin, etc. on steel or copper alloy substrates.

2) Sample and its cleaning The test piece itself can be used as the sample. The sample needs to be washed with pure solvents of benzene, light gasoline, trichloroethylene, or carbon tetrachloride, rinsed with absolute alcohol, and fully dried. (Related instrument: drying time Tester)

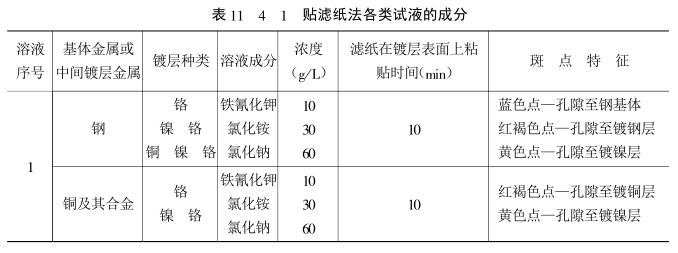

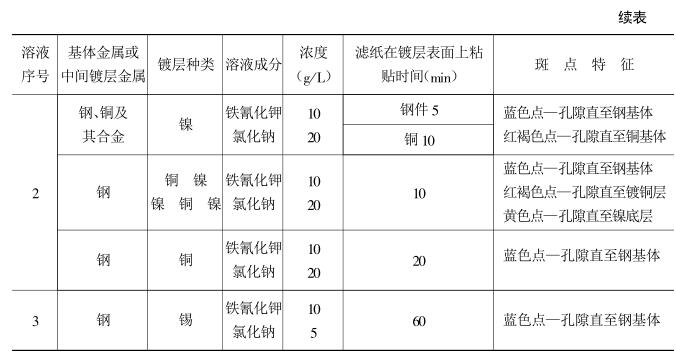

3) Test solution and its preparation Usually, the test solution is composed of corrosive agent and revealing agent. The corrosive agent is required to only act on the base metal or the intermediate coating without corroding the surface coating, and chlorides are generally used; the indicator is required to produce characteristic color development with the corroded metal ions. Commonly used ferricyanide charge and so on. The choice of test liquid should be determined according to the type of base metal (or intermediate coating) and the properties of the coating material. Refer to Table 11_4_1.

At room temperature, dissolve 10g of ferrocyanide [K4Fe(cN)6·3H20], 10g of ferrocyanide[K3Fe(CN)6·3H20] and 60g of sodium chloride (NaCl) in distilled water, and dilute to 1000mL, used after filtration. In principle, it is prepared and used immediately during the test, and it can also be kept in a dark place in a brown bottle for several days. Reagents should be chemically pure, and diluents should be distilled water.

4) Test paper Use fine-tissue filter paper.

5) Operation Wet the filter paper in the test solution, and brush the test solution on the sample to fully penetrate, and then paste the wet test paper, and stick it tightly without leaving any gaps. After a few minutes, take off the test paper, rinse it with water, stick it on a glass plate to dry, measure the number and size of colored spots, and convert it into the number of pores. The area of a test paper should be above 1ocm2.

According to the difference of base metal and coating material, it can be divided into the following situations:

(1) In order to show the pores up to the steel, copper or copper substrate, 4% ferrocyanide solution can be added to the filter paper with pore spots. At this time, the test solution and nickel layer already displayed on the filter paper The colored spots of the effect disappear, leaving blue spots to the steel substrate or red spots to the copper substrate.

(2) In order to display the pores up to the nickel layer, a solution of 5oomL/L25% ammonia water containing 2g/L dimethylglyoxime can be added to the filter paper with pore spots. At this time, the colored spots showing the nickel layer on the filter paper turned to rose red, while the colored spots originally showing the copper layer and the steel substrate disappeared.

(3) When inspecting the multi-layer coating whose outer layer is chromium layer, it should be left for 30 minutes after chrome plating. When the chromium layer on steel, copper, and copper alloy substrates is measured to the pores of the copper layer (copper substrate), the colored spots are not completely printed on the filter paper, so the filter paper can be removed and the red spots can be directly inspected on the coating surface.

6) Calculation For specific calculations, you can press the scale glass plate on the test paper, calculate the number and size of spots within 1cm2, and do the following calculation:

If the diameter is less than 1mm, it is counted as one spot;

If the diameter is greater than 1mm but less than 3mm, it is counted as 3 spots;

If the diameter is greater than 3mm, count as 10 spots.

final coat

Porosity = r/s

In the formula, n is the total number of spots; S is the counting sample area (1cm 2 ).