The principle of the paste method is the same as that of the filter paper method, but the filter paper is replaced by a paste, and the colored spots are displayed on the paste layer. In addition to the same scope of application as the filter paper method, it can also be used for curved surface samples. The specific process is to apply the paste containing the test solution evenly on the surface of the cleaned and dried sample, and the test solution in the paste penetrates through the pores of the coating and interacts with the base metal or the intermediate coating to form a characteristic color. Spots, by counting the number of colored spots on the paste, and finally evaluate the porosity of the coating.

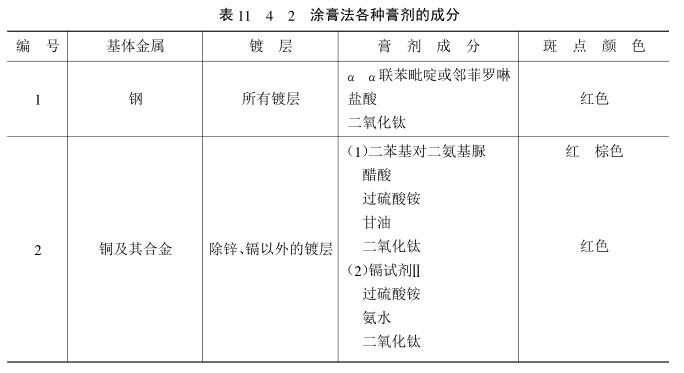

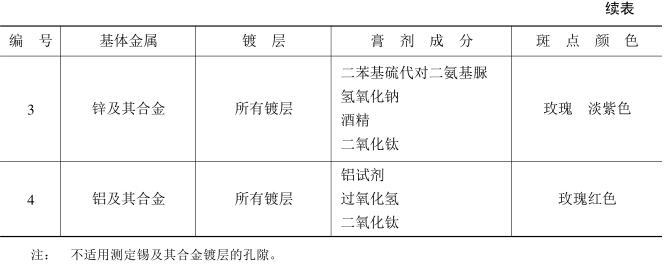

1) Components of the test paste The test paste is mainly composed of corrosive agent, indicator and paste. The functions and requirements of the corrosive agent and indicator are the same as those of the filter paper method. The mud paste material requires a white color and a stable chemical substance that does not interfere with the corrosion reaction. Titanium dioxide powder is commonly used. See Table 11_4_2 for details. (Related instruments: aging Test Chamber)

2) Preparation of test ointment No. 1 mud ointment: dissolve 0.1 ~ 0.2g of α_α biphenyl biphenyl or o-phenanthroline in 10mL of 0.1 ~ 0.2m0l/L hydrochloric acid solution, add 10 ~ 15g of titanium dioxide powder after dissolving, and make a lake standby. This ointment is valid for 14 days.

No. 2 mud cream: heat glacial acid in a Water Bath, measure and make 20% diphenyl-p-diaminocarburic acid solution, take 10mL of this solution and add 15~30g of titanium dioxide powder to make it into a lake shape. Then add 10% ammonium persulfate ammoniacal solution (the solution of ammonium persulfate directly dissolved in concentrated ammonia water and glycerin is reconciled, the volume ratio of the amount used is = solution 1 solution 2: glycerin = 1:1:0.5, after fully stirring Standby.The validity period of this ointment is 2~3 days.

No. 3 mud paste: add 5~15g ammonium persulfate and 5~20mL ammonia water (density 0.91) into 100mL distilled water to make ammonium persulfate ammonium solution, mix with 2% cadmium reagent (II) aqueous solution with the same volume, and then Add 12~15g of titanium dioxide powder to 10mL of the mixed solution, and make it into a lake shape for later use. This ointment is valid for 3 to 4 days.

No. 4 mud paste: Dissolve 0.05g diphenylthio-p-diaminourea in 10mL alcohol solution, add 20~30g titanium dioxide powder after dissolving, stir well, then add double volume of 0.5m0l/L sodium hydroxide solution , Adjusted into a lake shape for later use. The ointment is valid for 3-4 days.

No. 5 mud paste: Add 15~20g of titanium dioxide powder and hydrogen peroxide (density 1.14~1.15) equivalent to 1/2 volume of aluminum reagent solution (density 1.14~1.15) for every 10mL of solution in 2% aluminum reagent solution, and stir evenly Into a lake shape for later use. The ointment is valid for 3-4 days.

3) Test method The sample preparation method is the same as the filter paper method. Evenly brush the selected paste on the surface of the treated sample, and after 5-10 minutes, directly observe the number of colored spots on the paste layer. The amount of mud paste is 0.5~ lg/dm2.

4) Result inspection and evaluation The method refers to the filter paper method.