1. Impregnation method (perfusion method)

Using the chromogenic effect of the reagent to count the colored spots and measure the porosity of the coating, there is also the dipping method.

Dip the sample in the corresponding test solution or pour the corresponding test solution on a certain surface of the test sample, through the test solution penetrates into the pores of the coating and interacts with the base metal or the intermediate coating to produce colored spots on the surface of the coating, and then the coating The number and size of colored spots on the surface of the coating are counted to evaluate the porosity of the coating. This method is suitable for testing the porosity of cathodic coatings on the surface of steel, copper or copper alloys and aluminum alloy substrates.

2. Electrolytic imaging method

The sample to be tested is used as the anode, and the other auxiliary electrode is used as the cathode, and electrolysis is carried out in the corresponding electrolyte. The exposed base metal or intermediate coating in the pores of the sample is corroded by electrolysis, and then the corrosion point image and the number of corrosion points appearing on the sample surface are statistically analyzed to evaluate the porosity of the coating. This method is suitable for testing the porosity of various cathodic coatings.

3. Replacement method

The sample to be tested is immersed in the corresponding test solution, and the copper ion in the test solution is replaced by the substrate with a relatively negative potential to generate replacement copper spots in the pores of the coating, and then the number of converted copper spots on the surface of the sample is counted. to evaluate the porosity of the coating. This method is suitable for testing the porosity of nickel and chromium coatings on steel or zinc alloy substrates.

4. Microscopic measurement

Statistical porosity can also be observed directly with a microscope. Use a metallographic microscope with a certain magnification to directly observe the surface pores of the coating, or take parallel sections of the coating in sequence to observe the porosity. This method is suitable for testing the porosity of gold-plated and tin-plated layers.

According to the definition of coating porosity, the volume change of the coating is directly measured to calculate the porosity of the coating. There are buoyancy method, direct rod method, penetrating liquid rod method.

5. Buoyancy method

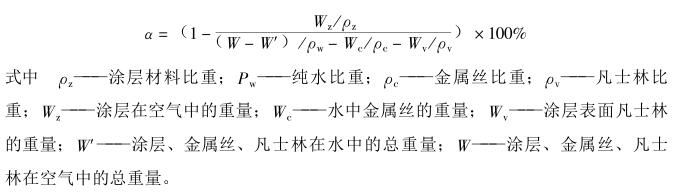

Gently peel off the coating from the sample substrate, and apply a thin layer of vaseline on the surface, then hang it with a thin wire, measure its different weights in air and water respectively, through the following Formula to calculate coating porosity.

6. Direct weighing method

7. Method of comparison based on air permeability

Breathability is the property of gases passing through the coating. It is closely related to the presence of stomata, but not necessarily expressed in porosity. Porosity only indicates the amount of pores in the coating, while air permeability is also affected by the directionality of the coating. Therefore, for corrosion-resistant and heat-resistant coatings, gas permeability is discussed as an important property. The porosity of coatings can be compared indirectly through the measurement of air permeability. The specific method is omitted. (Related instrument: temperature and humidity meter)

The above briefly explains the porosity of the coating and its various testing methods.