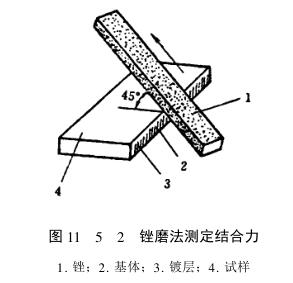

In this test method, a file, grinding wheel or steel tool is used to file, grind or grind the white substrate of the sample toward the coating direction. During the process of filing, grinding and grinding, the coating and the substrate are subjected to different mechanical forces and thermal expansion. Different, so that a component force is generated on the interface between the west and the west. When the component force is greater than the bonding strength of the coating, the coating will peel off (see Figure 11_5_2). (Related instruments: adhesion Tester)

This test is not suitable for very thin coatings and soft metal coatings such as zinc and cadmium, but is more effective for harder metal coatings such as aluminum alloy and copper. At the same time, this method is suitable for sprayed parts that are not easy to bend, entangle or suffer wear during use.

The specific conditions and methods of the test are as follows.

(1) Fix the sample on the vise, and use a file to file the white substrate in one direction toward the coating direction. The file and the coating surface form an angle of about 45°. After a certain number of files, the coating will not be lifted. Skin or peeling is acceptable.

(2) Clamp the sample with a tool, and grind the edge of the sample on a high-speed rotating grinding wheel. The grinding direction is from the substrate to the coating. After a certain period of grinding, the coating does not peel or No peeling is qualified.

(3) Use a hacksaw instead of a grinding wheel, and cut the edge of the sample from the substrate to the coating direction, and the coating is qualified if it does not peel off or peel off.