The heating and cooling test method is also called the thermal shock test method. It is to heat the tested sample at a certain temperature, then cool it down, and use the difference in deformation between the coating and the substrate due to the difference in thermal expansion coefficient to evaluate whether the coating's bonding force is qualified. When the force between the coating and the substrate due to temperature deformation is greater than its bonding force, the coating peels off.

This test is applicable to the situation where there is a significant difference in the thermal expansion coefficient between the coating and the substrate. For the sprayed parts, it is suitable for the sprayed parts that require heating or a large temperature difference in the use environment, such as parts of various heating equipment, lamps, etc. .

The specific test method is: heat the sample with a constant temperature box-type resistance furnace to a predetermined temperature, generally 0.5 to 1 hour, depending on the specific situation. After the sample is heated and kept warm, the sample is cooled naturally in the air, or directly put into cold water for cooling. Observe the surface coating of the sample, and if it does not peel or fall off, it means that the bonding force is qualified.

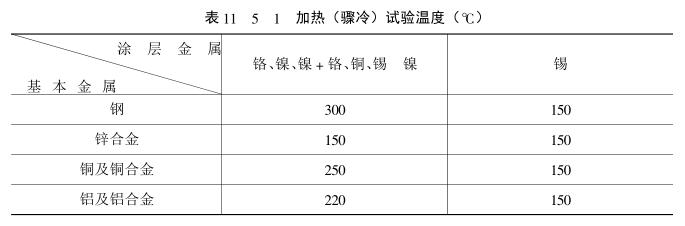

The sample heating temperature requirements are as specified in Table 11_5_1, and the temperature error is ±10°C. Certain easily oxidizable metals should be heated in an inert gas or in a suitable liquid. (Related instruments: constant temperature and humidity Test Chamber)