For the microhardness test, please refer to GB9790-88 metal coating and other related coating Vickers and Knoop microhardness tests.

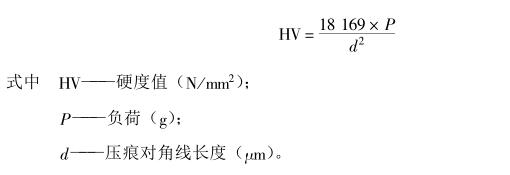

The microhardness method is to use a special diamond indenter on the microHardness Tester to press into the surface of the sample coating under the action of a certain static load to obtain the corresponding square pyramidal indentation. Then use the micro-eyepiece on the Hardness Tester to magnify the indentation by a certain magnification, and then measure the diagonal length of the indentation. The microhardness was calculated according to the following formula:

1. Inspection equipment

The equipment for testing the microhardness of the coating is a special microHardness Tester. If it is necessary to test the hardness through the coating profile, the test must be equipped with coating cutting, inlaying, polishing and other equipment to make samples.

Domestically produced microHardness Testers include Type 631, Type 71, Type Hx_1000 and many others.

The technical requirements of the microHardness Tester are as follows.

(1) The magnification is more than 600 times.

(2) The division value of the micrometer eyepiece is 0.01mm.

(3) The load weight is 10~200g.

(4) Workbench adjustment range: 10~40mm.

2. Inspection conditions

The test conditions such as the use environment, the surface state of the sample, the location of the test sample, the load weight, and the loading speed all affect the accuracy and precision of the test.

1) The use environment test should be carried out at a room temperature of 20+1°C, and the surrounding medium should be dry, free of dust and corrosive gases.

The instrument should be placed on a stable, vibration-free workbench and kept in a horizontal position.

2) Surface state of the sample The surface of the sample to be tested, whether it is a coating surface or a section, should be clean, flat and smooth, with a surface roughness Ra≤0.4.

3) Test position The test position of the sample can be the coating surface or section. When testing the coating surface, in order to prevent the influence of current density and edges, the center of the main surface should be taken as the center, and the interference of coating surface defects on the test should be avoided. In the same test part of the sample, the distance between the indentations should be more than 2.5 times the length of the diagonal of the indentation.

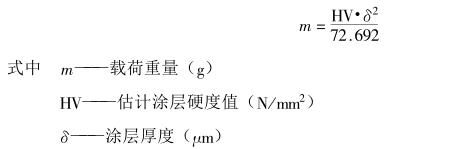

4) Load weight The size of the load should be selected according to the thickness and hardness of the surface coating of the sample. Usually, the load size can be estimated by the following formula:

5) Loading speed When measuring microhardness, the loading speed will directly affect the hardness measurement result, so it is required to select the appropriate speed when loading as close as possible to the state of static pressure. Usually choose about 30 seconds to complete the loading.

3. Inspection method

In order to ensure the accuracy of the coating hardness test, the inspection should be carried out according to the following steps.

1) Sample preparation The test site of the sample to be tested should be properly pretreated to make its surface flat and smooth, and cleaned to make its surface clean and free of oil and other dirt. When measuring the section hardness, it is necessary to prepare the sample according to the metallographic thickness measurement method.

2) Instrument inspection and calibration should be strictly and comprehensively inspected and calibrated according to the instrument product manual, so as to ensure that the instrument works normally, the indentation is clear and analyzed daily, the measured value is accurate, and meets the standard hardness value range.

3) Selection of load weight and loading speed Before actual operation, the load weight should be estimated according to the aforementioned formula according to the properties and thickness of the coating to be measured, and an appropriate loading speed should be selected, and a larger load should be selected as much as possible. and minimum loading speed.

4) Loading Place the test part of the test sample under the objective lens of the Hardness Tester, after selecting a suitable position for the indentation, slowly move it under the diamond indenter of the Hardness Tester, and then load it evenly and slowly, Stop loading until the indicator light of the instrument indicates that the loading has reached the selected load, and immediately remove the load.

5) Observing the indentation Move the sample under the objective lens of the Hardness Tester, through the eyepiece of the Hardness Tester, you can clearly see the square pyramidal indentation and the diagonal line of the indentation on the sample.

6) Measure the length of the indentation Accurately measure the length of the two diagonals of the indentation. If the lengths of the two diagonals are equal or close, the measurement is valid. Then calculate the average value of the diagonal length, and look up the table or calculate the hardness value of the coating accordingly.

7) Repeated operation For the same sample, the above steps should be followed, and the measurement should be repeated more than three times under the same conditions, and the arithmetic mean value should be taken as the final measurement result of the coating hardness.