When the color paint is removed into a uniform film, the background color on the surface of the paint removal can no longer appear. This performance of color depth is called hiding power (covering power). This property is related to the optical phenomena that occur in pigmented paint molds.

When a beam of light is cast on the paint film, part of the light is directly reflected back from the surface of the paint film, while the other part of the light is reflected in a diffuse state by the pigment particles in the paint film. The hiding power of the pigment directly depends on the amount of reflected light, the difference in refractive index between the material and the binder, and the size (dispersion) of the pigment particles.

Reflected light is the sum of the mirror images (opposite images) formed when light passes from one medium into another. Therefore, the finer the pigment particles, the better the ability of a certain amount of pigment to cover the surface, because the finer the particles, the more mirror images (opposite images) reflected by a certain amount of pigment, so the more light is reflected and the amount of light is reflected. Also bigger. But when the particle size becomes less than half of the light wavelength, the speed difference force of the pigment begins to decrease. For example, if the size of the particles is less than 0.2µ, a paint with very good hiding power cannot be produced. (Related instrument: hiding power paper)

Pigments with a particle size of about 1 µ have good hiding power. When the size of the pigment particles is such that a small amount of color paint can be used to cover a certain area of the surface. For example, the grain size of zinc white is very close to this moderate size, so the hiding power of zinc white is better than that of pin white of the same weight, although pin white has a higher refractive index than zinc white.

The hiding power of SiO2 increases gradually with the particle dispersion increasing to 0.3µ. With the increase of the number of particles with a diameter less than 0.3µ in the pigment, the capping force will continue to decrease. In conclusion, it can be considered that with the decrease of the particle size, the speed blue force of the highly dispersed pigment should decrease.

The hiding power not only depends on the size of the pigment particles, but also depends on the difference in size between different types of particles and the respective content of the particles with different particle sizes in the pigment. If they are pigments with the same degree of dispersion, it can be inferred that there is a free space not filled by particles in the cluster of spherical particles. In the case of a variety of pigments with different dispersion degrees (that is, when there are granules with different diameters), some granules with smaller diameters try to scatter in the middle of larger granules, resulting in a denser pigment pile. cluster (pigment group), thus increasing its hiding power. It is generally believed that in order to make the small granules disperse between the large granules, the radius of the small granules should be at least % of the radius of the larger granules. Therefore, pigments with various degrees of dispersion in such a ratio between large particles and small particles can form denser clusters (cis) in the paint film than pigments with the same degree of dispersion, so their disk strength should also be greater. Some.

Gurevich believes that this explanation is incorrect, and pointed out that the increase in the friction force is caused by the reduction of the oil absorption of the pigment in this case, which also improves the covering power of the paint. When converted into dry When using pigments, the speed difference force does not change with the particles in the paint: it only changes with the density of (groups).

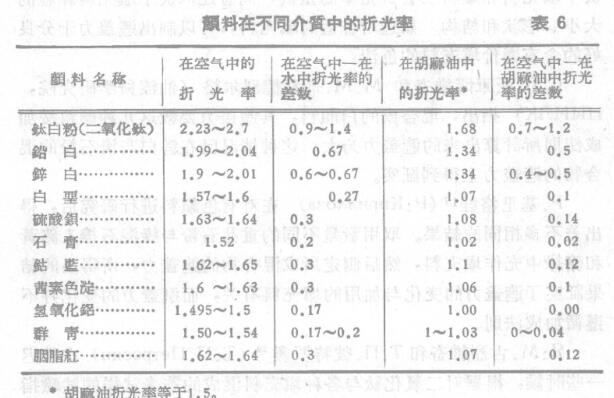

In addition, it should also be pointed out that due to the result of grinding, the color paint and hiding power have increased. When grinding pigments with a high degree of dispersion, the increase in the separation power of the color paste is due to the large aggregates of the particles being dispersed. Therefore, the increase in stress force of highly dispersed pigments is entirely due to the disintegration of pigment agglomerates in the binder (oil), because when the pigment is mixed with the oil, the pigment is not separated into individual particles. Therefore, the agglomerates are dispersed in the oil. In addition to the degree of dispersion, the hiding power also depends on the refractive index of the pigment. The larger the light resolution, the better the reflection of light, and the higher the selection power, the better the hiding power of the paint. The differential force depends on the difference in refractive index between the pigment and the binder (film-forming material) that surrounds the firing pigment particles. The larger the difference, the higher the differential force. (Related instrument: refractometer)

When making colored paints, colloidal binders, oils, etc. can be used as the first mixture. The covering power of the pigments also varies with the medium in which the pigments are dispersed, so some materials may be more effective in one medium. well, and in another medium the velocity difference is very poor, for example, we know that chalk is in the Poway water droplet or in a mixture containing water soluble matter (new light ratio 1.6) In this method, a paint with good opacity can be produced. This is because after the water evaporates, there are spaces filled with air (the refractive index of which is close to 1) in the coating film, but the whitening should be done in oil, cooked oil or varnish. In the evolution of film-forming substances such as ions, it is impossible to produce a color paint with a difference. This is because the refractive index of white (1.6) has a large difference with the new light index of air (1.0), but it is different from the refractive index of oil (1.0). The new light rate (1.5) is not much different.

When the refractive index of the pigment is the same as that of the film-forming substance, the pigment will appear transparent, for example, the white should be in the oil, the silver alumina should be in the oil, the pigment lake should be in the oil, etc., in the oil The pigment that is placed on the base of the film-forming substance or appears transparent in a substance with a refractive index between 1.5 and 1.65 is called a transparent pigment (eccupyn_M), such as the refractive index of the pigment is greater than that of the film-forming substance Rate, such pigments are called speed difference pigments.

If the hiding ability of the paint is caused by the difference in light rate between the pigment and the film-forming material, rather than the size of the sub-pigment particles, it is called the combination of fast blue power or transparency, and the combination of the hiding power system It is expressed by the difference between the refractive index of the pigment (in air) and the shading light rate of the film-forming substance. In the case of complete transparency, this difference is equal to zero (such as aluminum hydroxide in the oil-forming oil).

Table 6 lists the refractive index of some pigments and the difference between the refractive index of these pigments and the refractive index of water and oil,

It should be noted that dark pigments (especially black pigments) do not reflect light, but only absorb light; so the speed difference of dark pigments does not depend on the reflection of light, but on the ability to absorb light, in fact There is no difference between the opacity caused by the reflection of sub-light and the opacity caused by the absorption of light. It is often necessary to solve such a problem: that is, what kind of pigment and a certain binder can be used to remove the opacity. to decorate the largest surface and at the same time to completely conceal it, according to which the selective force is expressed in grams of pigment (or varnish) necessary to cover an area of 1 m- of the colored surface; or It is expressed by the number of meters of the colored surface that can be brushed by 1 kg of pigment (color paint). In such a painting situation, the color paint layer should be impermeable to measure the colored bottom surface.