The weight of the pigment that cannot pass through the sieve (this section can indicate the fineness of the pigment) is called the sieve residue. The sieve residue is expressed as a percentage of the total weight of the pigment.

The test results can also directly express the fineness of pigments and the total amount of large grains and impurities (related instruments: Fineness Meter). The dry sieving method is only used when it is impossible to use a wet liquid and when there are corresponding provisions in the technical conditions. In all other cases, the wet sieving method described below is used.

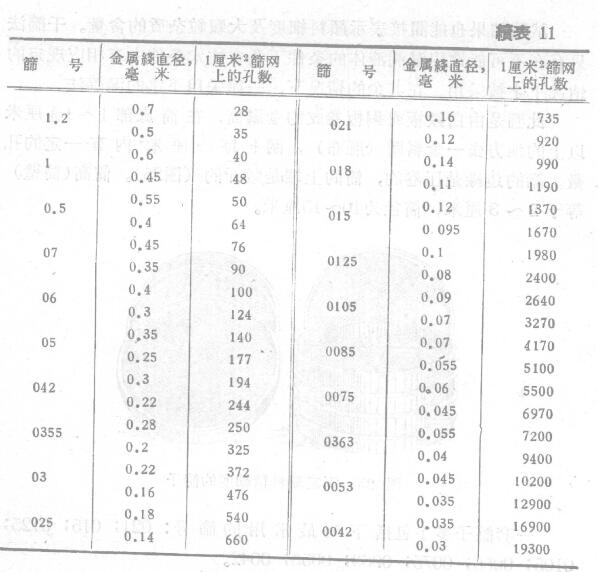

The sieve is a metal cylinder rolled from a white iron plate or a copper plate, and a metal mesh (linen) is stretched at the bottom of the cylinder at one-half, and there are a certain number of holes in each centimeter of the mesh. The sides of the sieve are rolled, and the upper end of the cylinder is open (Figure 25). The tube height (tube wall) is equal to 2-3 cm, and the tube diameter is 10-15 cm.