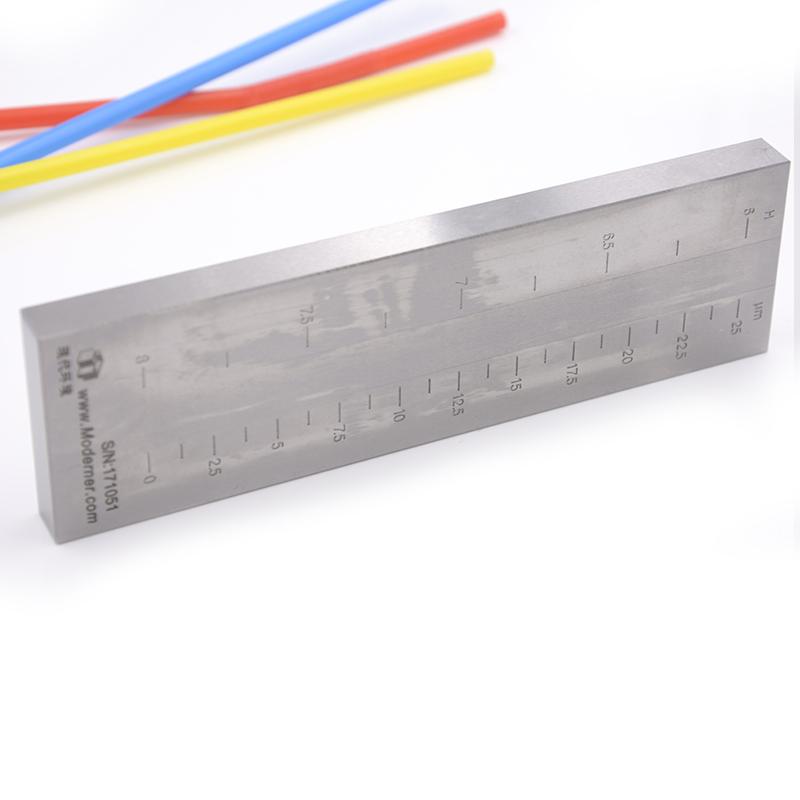

Scraper Gauge

A fineness gauge is a tool used to measure the particle size of paints, paints, inks and other viscous substances. It usually consists of a long, straight filament or scraper and a graduated stand. Place the substance to be tested on the support, then flatten it with a filament or a scraper and separate the particles, and finally determine the particle size of the particle or the viscosity of the slurry by reading the scale value on the scraper or filament. The scraper Fineness Meter is one of the commonly used quality control tools in the production process of coatings and paints, and it is also one of the required tools for the development and research of coating formulations.

Color paste fineness

The fineness measurement of colorants is an important quality control parameter in the production of coatings and printing inks, and an essential step in formulation development and research. Measuring the fineness of color paste can determine its viscosity and fluidity, which has an important impact on the construction and printing quality of coatings and inks.

If the fineness of the color paste is too low, it means that its viscosity is too high, which may cause the pigment to not be evenly distributed or not easy to flow during construction or printing, resulting in uneven color or spots. If the fineness of the color paste is too high, it means that its viscosity is too low, which may cause the pigment to flow too fast during construction or printing, and the concentration and depth of the pigment cannot be controlled, thereby affecting the quality of the coating.

Therefore, measuring the fineness of the color paste can help adjust its formula, control its viscosity and fluidity, so as to ensure the uniformity, consistency and stability of the pigment during construction or printing.

Steps

The following are the general steps to measure the fineness of color paste using a scraper Fineness Meter :

Prepare the scraper gauge: Clean the scraper gauge to ensure that the surface is clean and free of impurities.

Prepare the color paste to be tested: Stir the color paste to be tested evenly to ensure that the pigment is evenly dispersed and avoid precipitation. Then put the color paste into a flat measuring container.

Measuring the fineness: put the scraper fineness gauge on the surface of the color paste, use the handle of the scraper Fineness Meter to move the scraper along the surface of the color paste, so that the color paste fills the scale groove of the scraper Fineness Meter.

Record the reading: Take the scraper fineness gauge out of the color paste, and scrape off the excess color paste from the scraper with a brush or other cleaning tools. Then use a reading microscope or the naked eye to observe the distribution of the pigment on the scraper, read the scale value of the finest particle, and record it.

Determine the fineness grade of the color paste from the recorded data: compare the measurement results with the standard provided by the pigment manufacturer, and determine the fineness grade of the color paste according to the standard.

Precautions:

Before measurement, the scraper fineness gauge needs to be cleaned to avoid old pigment residues affecting the measurement results.

When stirring the color paste to be tested, the color paste should be stirred evenly to avoid pigment precipitation.

The scraper fineness gauge should be placed horizontally during measurement to ensure the accuracy of the measurement results.

When measuring, the scraper fineness gauge should be placed gently on the surface of the color paste, and keep moving smoothly to avoid air bubbles and other disturbances.

The measurement should be read at the finest particle to determine the fineness grade of the color paste.