Abrasion methods

There are several methods for testing the abrasion resistance of paint or coatings. These tests evaluate a coating's ability to withstand wear and tear, rubbing, or scratching under various conditions. Some common methods include:

Taber Abrasion Test: The Taber Abraser is a widely used instrument for measuring the abrasion resistance of coatings. It uses two abrasive wheels that rotate and rub against the coated surface, while the sample rotates beneath them. The weight on the wheels and the number of cycles can be adjusted to apply different levels of abrasion. The abrasion resistance is calculated based on the weight loss of the sample or the number of cycles required to wear through the coating.

Falling Sand Abrasion Test: In this test, a controlled stream of abrasive particles, such as sand or aluminum oxide, is allowed to fall onto the coated surface from a specified height. The abrasion resistance is determined by measuring the weight loss of the sample, the depth of the wear track, or the time it takes to wear through the coating.

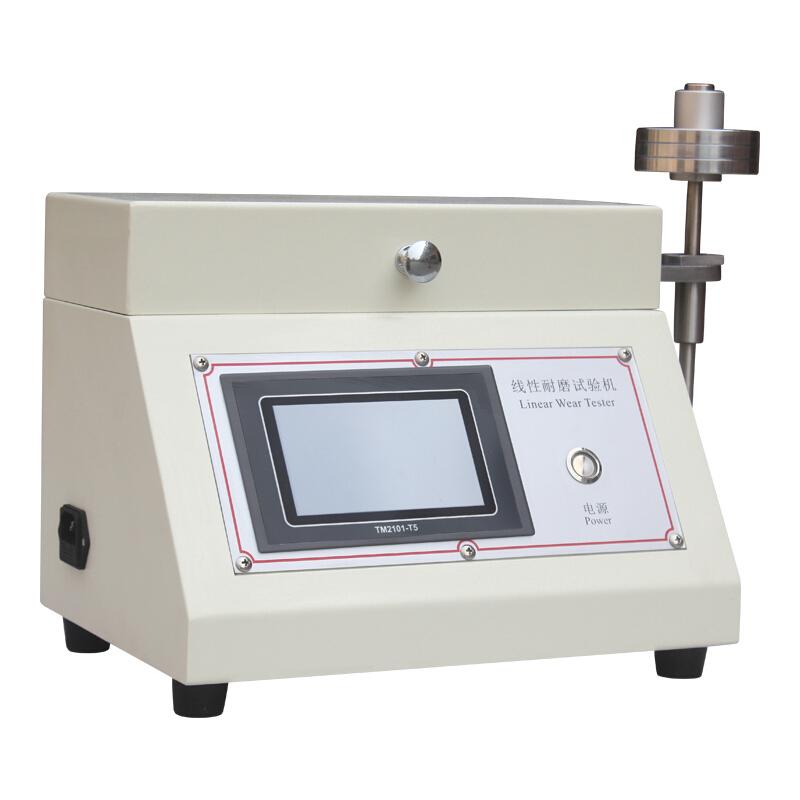

Linear Reciprocating Abrasion Test: This test involves moving a coated sample back and forth under an abrasive tool or material, such as a brush or a cloth, with a specified force. The abrasion resistance is calculated based on the number of cycles required to wear through the coating or the depth of the wear track.

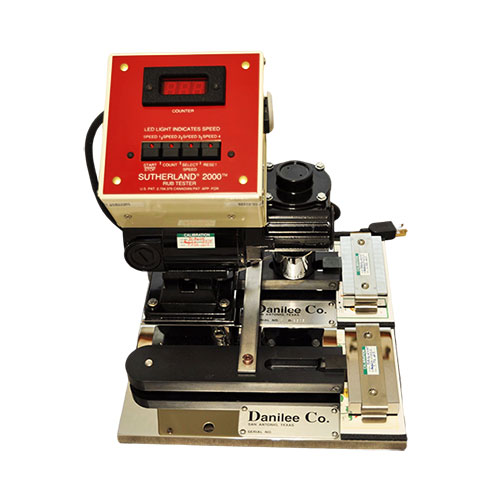

Sutherland Rub Test: The Sutherland Rub Test is a method for evaluating the abrasion resistance of printed materials or coatings under rubbing. The sample is rubbed against a weighted abrasive material or another sample for a specified number of cycles. The abrasion resistance is determined by assessing the degree of wear, discoloration, or damage to the printed or coated surface.

Crockmeter Test: This test is commonly used to evaluate the abrasion resistance of textiles, but it can also be applied to coatings. The coated sample is rubbed against a standardized abrasive material using a crockmeter, which applies a consistent pressure and stroke length. The abrasion resistance is assessed by examining the wear or transfer of the coating onto the abrasive material.

Test steps

These are just a few examples of abrasion resistance test methods, and there may be additional methods or variations specific to certain industries or applications. It's essential to choose the appropriate test method based on the coating's intended use, industry standards, and the specific properties being evaluated.Here are the test steps for each of the mentioned abrasion resistance test methods:

Taber Abrasion Test:

a. Prepare the coated sample according to the relevant standard or test requirements.

b. Mount the sample on the Taber Abraser's turntable.

c. Select the appropriate abrasive wheels and weights according to the test standard or requirements.

d. Lower the abrasive wheels onto the sample surface.

e. Set the desired number of cycles for the test.

f. Start the test and allow the Taber Abraser to run until the set number of cycles is completed.

g. After the test, evaluate the abrasion resistance based on the weight loss of the sample or the number of cycles required to wear through the coating.

Falling Sand Abrasion Test:

a. Prepare the coated sample according to the relevant standard or test requirements.

b. Mount the sample in the test apparatus, ensuring the coated surface faces upward.

c. Fill the abrasive material (such as sand) into the abrasive storage container.

d. Set the test parameters, such as the flow rate of the abrasive material and the test duration.

e. Start the test and allow the abrasive material to fall onto the sample surface.

f. After the test, evaluate the abrasion resistance based on the weight loss of the sample, the depth of the wear track, or the time it takes to wear through the coating.

Linear Reciprocating Abrasion Test:

a. Prepare the coated sample according to the relevant standard or test requirements.

b. Mount the sample in the test apparatus, ensuring the coated surface faces upward.

c. Select the appropriate abrasive tool or material and set the required force.

d. Position the abrasive tool or material above the sample.

e. Set the desired number of cycles for the test.

f. Start the test and allow the abrasive tool or material to move back and forth across the sample surface until the set number of cycles is completed.

g. After the test, evaluate the abrasion resistance based on the number of cycles required to wear through the coating or the depth of the wear track.

Sutherland Rub Test:

a. Prepare the coated or printed sample according to the relevant standard or test requirements.

b. Mount the sample in the test apparatus, ensuring the coated or printed surface faces upward.

c. Select the appropriate abrasive material or counter-sample and set the required weight.

d. Position the abrasive material or counter-sample above the sample.

e. Set the desired number of rub cycles for the test.

f. Start the test and allow the abrasive material or counter-sample to rub against the sample surface until the set number of cycles is completed.

g. After the test, evaluate the abrasion resistance by assessing the degree of wear, discoloration, or damage to the coated or printed surface.

Crockmeter Test:

a. Prepare the coated sample according to the relevant standard or test requirements.

b. Mount the sample on the crockmeter's base, ensuring the coated surface faces upward.

c. Select the standardized abrasive material and attach it to the crockmeter's rubbing finger.

d. Position the rubbing finger above the sample.

e. Set the desired number of rub cycles for the test.

f. Start the test and allow the rubbing finger to move back and forth across the sample surface until the set number of cycles is completed.

g. After the test, evaluate the abrasion resistance by examining the wear or transfer of the coating onto the abrasive material.

Please note that the exact steps may vary depending on the specific test apparatus or standard being followed. Always consult the relevant test standard or guidelines for accurate and reliable results.