What is a coating stick?

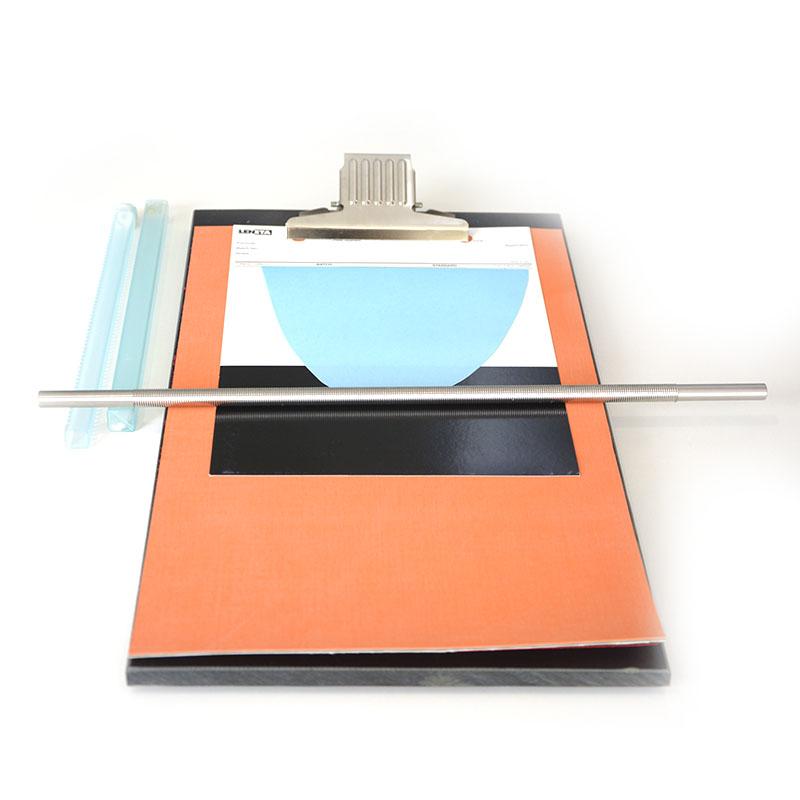

A coating rod is a precision coating tool used to apply a controlled and consistent thickness of a liquid material such as a coating, adhesive, ink, varnish or other liquid to a substrate surface. Based on the perspective of this article, this article uses a wire-wound coating rod as an introduction. The operation steps and usage skills of the extrusion process are generally similar.

Coating rods generally consist of a cylindrical rod, usually made of stainless steel, with a wire or filament tightly wound around its surface. The wire or filament forms helical grooves or channels along the length of the rod, allowing precise control of coating thickness.

How to apply the film?

Using a wirewound applicator stick typically involves the following steps:

Choose the right coating stick for your specific coating application. Consider factors such as the type of material to be applied, coating viscosity, and desired coating thickness.

Make sure the surface to be coated is clean, dry and free of any debris or contamination. If necessary, sand, clean, or prime the surface according to the manufacturer's instructions.

Coating material is applied to wirewound coating rods using a suitable method, such as dipping or pouring. Ensure that the coating material is evenly distributed along the length of the rod and fills the helical grooves or channels created by the wire wound or filament.

Hold the wire-wound applicator stick and slide it smoothly across the surface in a controlled manner, applying gentle, even pressure. The helical grooves or channels created by the wound wire or filament will control the thickness of the coating applied to the surface.

Depending on coating material and desired thickness, you may need to use a wirewound applicator applicator for multiple applications. Allow each coat to dry or cure according to the manufacturer's directions before applying additional coats.

After use, thoroughly clean wire-wound applicator sticks with an appropriate cleaning solvent or method, following the manufacturer's recommendations. Store sticks in a dry, clean place to prevent damage or contamination.

Always follow the manufacturer's safety guidelines and instructions for the specific wirewound applicator stick and coating material being used. Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and respiratory protection when necessary.

skills

control speed and pressure

When applying coatings with a coating rod, it is important to maintain consistent speed and pressure to achieve a uniform coating thickness. Too much pressure or too fast will result in too much coating being applied, while too little pressure or too slow will result in an uneven coating.

Adjust bar size and wire row spacing

Wire Wound Coating Rods are available in various sizes and wire spacing which determine the coating thickness, choose the appropriate rod size and wire row spacing according to the desired coating thickness and the viscosity of the coating material .

Test and adjust

Before applying the coating on the actual substrate, some test runs on scrap or sample substrates are recommended to determine the optimum speed, pressure and rod size for a particular coating application. Make adjustments as needed to achieve the desired result.

keep the bar clean

Clean the wirewound applicator rod periodically during the coating process to remove any excess coating or buildup that may affect the thickness of the coating. Use the appropriate cleaning method or solvent recommended by the manufacturer.

properly stored

Store wire wound applicator sticks in a clean, dry place when not in use to prevent rust or contamination that could affect its performance. Avoid bending or damaging the wire or filament during storage.