The main function of the squeegee is to control the wet film thickness (WFT) of the applied liquid coating. The diameter of the bar and the row spacing determine the thickness of the coating as the liquid flows between the wire windings and is evenly distributed on the substrate as the wires are wound. The bar row spacing can be varied to achieve a wide range of coating thicknesses, making the bar a versatile tool for achieving precise and consistent coating thicknesses in a variety of applications.

One of the key advantages of using a bar is its ability to deliver consistent and repeatable coating thicknesses, ensuring uniformity in the final coated product. This is especially important in industries such as printing, coatings, adhesives and electronics, where precise control of coating thickness is of paramount importance to achieving the desired properties and performance of the final product. By using a bar, manufacturers can ensure that coatings are applied evenly and consistently, reducing the risk of defects or inconsistencies in coated products. In addition, the bar prevents over-application or excessive coating thickness, which can lead to problems such as poor adhesion, cracking or uneven drying, which can negatively affect the quality and performance of the coated product. The spacing between the wire rows on the wire-wound rod acts as a gauge or drawdown blade to control the amount of coating applied to the substrate, preventing excessive coating thickness and thus helping to achieve the desired coating properties and performance.

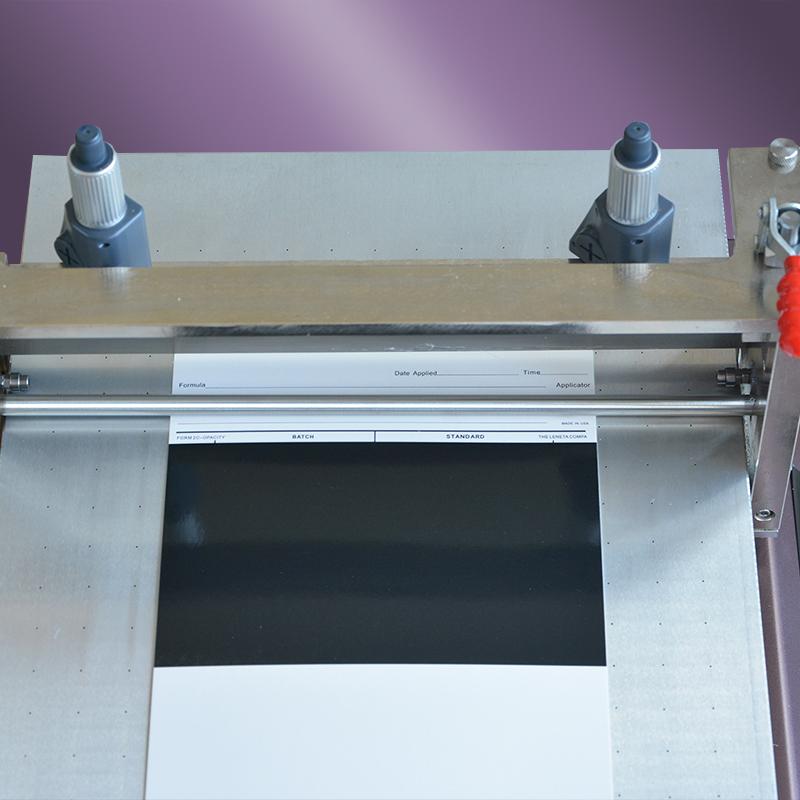

When coating ultra-thin films, the scraper is often used with a film coating machine for coating, which allows operators to reduce manual coating errors, constant pressure, constant speed, and even provides functions such as heating, drying, curing, and automatic ink filling.

Using a spatula with an automatic Film Applicator involves the following steps:

Set up the automatic Film Applicator: Follow the manufacturer's instructions to properly set up the automatic Film Applicator, including adjusting speed, height, and other parameters for your specific film application needs.

Inserting the Squeegee: Insert the squeegee into the appropriate holder or attachment on the automatic Film Applicator. Make sure it is securely fastened and aligned correctly.

Load Coating Material: Load coating material into the reservoir or container of the automatic Film Applicator following the manufacturer's instructions. Ensure coating materials are properly mixed and at the viscosity required for the specific application.

Set desired coating thickness: Adjust the bar size and line spacing on the automatic Film Applicator to achieve the desired coating thickness, this may require changing the bar to a different size or adjusting to the specific requirements of the coating application line spacing.

Start the automatic Film Applicator: Turn on the automatic Film Applicator and start the film coating process according to the manufacturer's instructions. The automatic Film Applicator moves the squeegee across the substrate surface at the set speed and height, spreads the coating material and follows the squeegee bar. Dimensions and Line Spacing control thickness.

Monitoring the Coating Process: Monitor the coating process to ensure that the coating is applied evenly at the desired thickness. Adjust the speed, height, or other parameters of the automatic Film Applicator as needed to maintain the desired coating thickness.

Completion of the coating process: After the coating process is complete, turn off the automatic Film Applicator and remove the squeegee from the stand or attachment. Clean the squeegee thoroughly according to the manufacturer's instructions, then store it properly.

Cleaning Automatic Film Applicators: Clean automatic Film Applicators, including reservoirs or containers for coating material, according to the manufacturer's instructions to remove any residual coating material and prevent clogging or damage.

Follow Safety Precautions: Always follow proper safety precautions, including wearing appropriate personal protective equipment, working in a well-ventilated area, and following manufacturer's instructions and recommendations for safe use of automatic Film Applicators and applicators.

It is important to refer to the specific instructions provided by the automatic Film Applicator and bar manufacturer for effective film application. Based on the experience of the northern and southern tides, for example, when the viscosity of the material is greater than 1000cp, it is necessary to use an open-type scraper, and when the viscosity of the material is greater than 3000cp, it is necessary to use a wet film preparer for coating. When using a bar with an automatic Film Applicator, it cannot be overemphasized that proper setup, adjustment, monitoring and cleaning are critical to achieving consistent and controlled coating thickness.