Testing purposes

Battery high-low temperature testing is important to assess the safety, reliability and performance of batteries under a range of environmental conditions to ensure effective operation in a variety of applications. High temperature testing is designed to evaluate a battery's ability to handle high temperatures. Because when the battery is exposed to high temperature, it will lead to a decrease in performance, capacity and cycle life, and in some cases, even cause the battery to catch fire or explode. Therefore, high-temperature testing is necessary to ensure that batteries can operate safely and reliably in high-temperature environments. The low temperature test mainly evaluates the performance of the battery at low temperature. Low temperatures can also negatively impact battery performance and capacity, affecting the battery's ability to power a device or vehicle. Low-temperature testing helps determine how batteries perform in extremely cold temperatures and whether they can continue to operate under these conditions.

Test Methods

There are several ways to perform battery high-low temperature testing, depending on the specific requirements of the battery being tested and the testing standards that need to be followed. Here are some common methods used for these tests:

1. Environmental chamber test:

Environmental chamber testing involves placing batteries in chambers that simulate extreme temperature conditions, such as high or low temperatures, humidity, and other environmental factors. The chamber can be heated or cooled to the desired temperature, and the battery's performance can be monitored to assess its response to these conditions.

2. Constant current discharge test:

The method involves discharging the battery at a constant rate while exposing it to high or low temperatures. Battery performance can be evaluated by monitoring the rate of discharge and the temperature of the battery over time.

3. Cycle test:

This method involves subjecting the battery to repeated charge and discharge cycles while exposing it to high or low temperatures. This is a more comprehensive test that evaluates the battery's performance over an extended period of time and provides insight into how the battery will perform in various usage scenarios.

4. Accelerated aging test:

Accelerated aging testing involves exposing batteries to elevated temperatures for extended periods of time to simulate the effects of long-term use. The test can provide insight into how a battery will perform over its useful life and help manufacturers identify potential problems early on.

The specific test method used will depend on the type of battery being tested, the application it will be used in, and the test standards that need to be met. It is important that these tests are performed in a controlled environment and under strict testing protocols to ensure accurate and reliable results.

case analysis

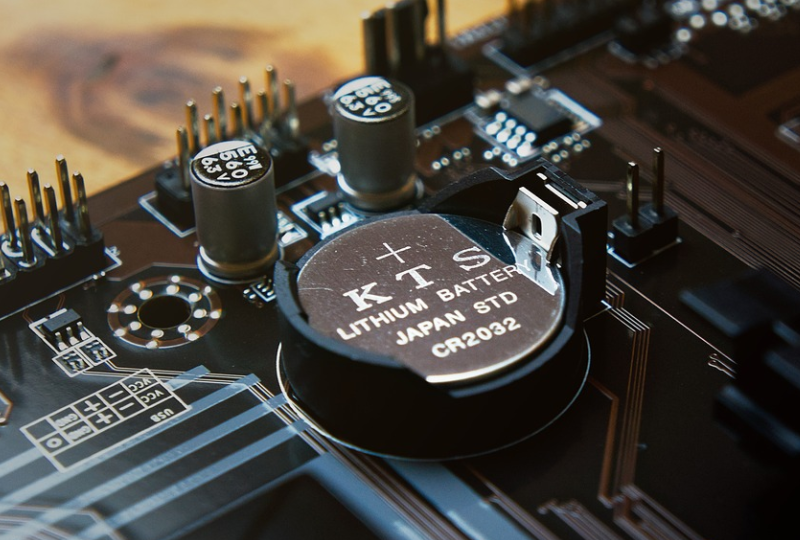

Take the button battery high-low temperature test as an example. Lithium button batteries are commonly used in a wide range of electronic equipment, from watches and calculators to medical equipment and remote controls. These batteries are known for their high energy density and long life, but they are also sensitive to temperature changes.

A low/high Temperature Test Chamber that can be controlled at temperatures between -60°C-150°C simulates extreme temperature conditions and determines how batteries will perform under these conditions. In addition to temperature control, the battery test system should also be able to charge and discharge the battery according to your test requirements. You should ensure that the test system is compatible with the specific type of lithium coin cell you are testing, as different cells may have different charging and discharging characteristics.

When temperature testing a lithium coin cell battery, it is important to ensure that the battery is charged and discharged according to the manufacturer's specifications. This will help ensure that test results are accurate and reliable. In addition to temperature control, battery testing systems used in conjunction with Test Chambers should also be designed to work with lithium coin cells. This could include features such as programmable charge and discharge cycles, built-in safety mechanisms to prevent overcharging or overheating, and compatibility with different types of lithium coin cells. In order to test the performance of lithium button batteries under different temperature conditions, a low and high Temperature Test Chamber is used. The chamber is designed to simulate extreme temperature conditions, ranging from -60°C to 150°C, and can be used to test the capacity, discharge rate and other characteristics of the battery. In the actual test, the test hole and insulating board can be added through the high-low temperature test box, and the battery testing equipment can be placed in the studio for testing. For details, please consult NBCHAO for a complete set of solutions.

Testing lithium coin cells in a low/high Temperature Test Chamber is an important step in ensuring their safety and reliability, especially for applications where the battery may be exposed to harsh environmental conditions. By simulating these extreme conditions, battery manufacturers can better understand how their products will perform in the real world and take steps to improve their designs and performance.