Wet Film Thickness (WFT) is the thickness of paint, paint or other coatings before they are applied to a surface and dry. This parameter is very important for the quality and performance of the coating, because it directly affects the final dry film thickness (Dry Film Thickness, referred to as DFT), which in turn affects the protection performance, durability and appearance of the coating.

During the construction process, by controlling the wet film thickness can ensure that the coating reaches the expected dry film thickness. Wet film thickness can be measured with special measuring tools, such as wet film comb gauge or wet film wheel gauge . These tools measure the thickness of the coating while it is wet and provide an approximate thickness value. By adjusting the viscosity of the paint, the method of application or the speed of application, etc., the wet film thickness can be controlled to achieve the desired coating effect.

Preparation of Wet Film Thickness

If you wish to prepare a coating of a specific wet film thickness, follow these steps:

Choose the right paint or coating: Choose the right paint or coating based on the desired coating properties, the type of substrate, and the application environment. Typically, the technical data sheet (TDS) for a coating will provide suggested wet film thickness and dry film thickness ranges.

Prepare the substrate surface: Make sure the surface to be coated is clean, level and free of oil, dust and loose matter. This helps the paint adhere better to the surface, improving the quality of the finish.

Stirring the paint: According to the paint manufacturer's instructions, stir the paint thoroughly. If dilution is required, use the appropriate thinner as directed.

Choose the right painting equipment: choose the right painting equipment, such as brushes, rollers, spraying equipment, etc., according to the type of paint and construction requirements.

Wet film thickness control during the coating process: During the coating process, the required wet film thickness can be achieved by adjusting the viscosity of the paint, brushing method or brushing speed and other factors. Common wet film thickness control knife coating tools include: wire Bar Coater, knife coater or automatic Film Applicator.

Drying and Curing: Allow coating to dry at proper temperature and humidity according to paint manufacturer's recommendations. Ensure that the coating is sufficiently dry and cured to achieve the desired dry film thickness and properties.

Check the dry film thickness: After the coating is dry, use a dry Film Thickness Gauge to check the thickness of the coating to make sure it is as desired. Additional coats may be required if thickness is insufficient.

Evaluate the coating quality: evaluate the dried coating, check appearance, adhesion, corrosion resistance and other performance indicators to ensure that the coating meets the expected quality requirements.

Measurement of Wet Film Thickness

Wet film thickness can be measured using specialized tools such as wet Film Thickness Gauge or wet film wheel. Here's how to measure wet film thickness with these tools:

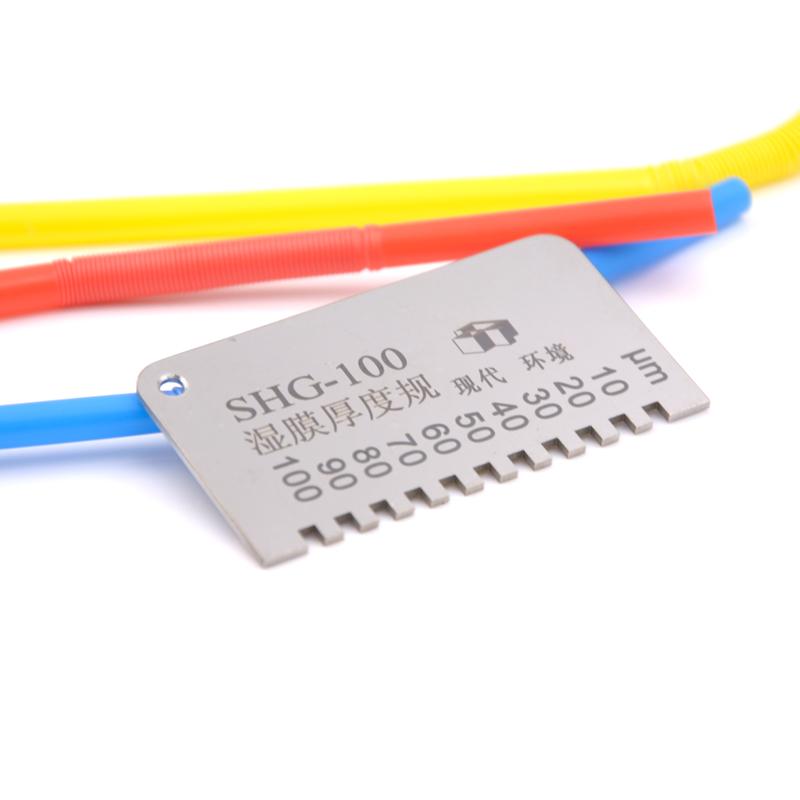

1. Wet film comb gauge : The wet Film Thickness Gauge is usually a metal or plastic sheet with a scale, and its edge is jagged. The method of use is as follows:

a. Insert the serrated edge of the Wet Film Thickness Gauge vertically into the freshly applied coating, making sure not to disturb the coating.

b. Lift the Wet Film Thickness Gauge slightly from the paint surface and check for paint marks on the notched scale.

c. Locate the last scale with paint marks, and the first scale without paint marks. The wet film thickness lies roughly between these two scales.

d. Clean the wet Film Thickness Gauge for the next use.

2. Wet film wheel : The wet film wheel is a roller with a measuring scale, which can be rolled on the surface of the paint to measure the thickness of the wet film. The method of use is as follows:

a. Place the wet film wheel on the freshly applied paint surface so that the roller makes contact with the paint.

b. Roll the wet film wheel a short distance over the surface of the paint so that the paint marks along the scale of the roller.

c. Check for paint traces on roller scale to find highest mark covered by paint. The value corresponding to this scale is the wet film thickness.

d. Clean the wet film wheel for next use.

During the coating process, it is recommended to measure the wet film thickness several times to ensure a consistent coating thickness. Take care to avoid damaging the coating surface during the measurement. After the coating is dried, the dry film thickness can be measured with a dry Film Thickness Gauge to further evaluate the quality of the coating.