CB and Kubovier and Pn Goliak proposed an accurate method for measuring the grinding fineness of colored paints. This method can not only test the grinding degree of finished colored paints, but also control the entire production process in the workshop. Select row control. The determination of the grinding fineness is carried out by means of a common microscope (100~500 times magnification).

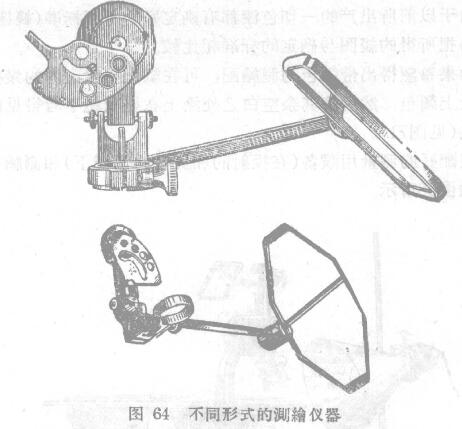

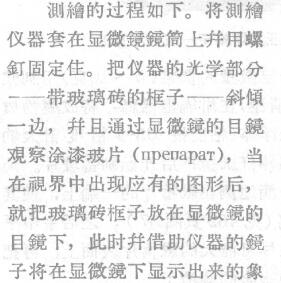

The measuring device shown in Fig. 64 is composed of the following parts: the optical glass placed in the metal sample ; the movable housing connected with the metal frame by the long axis; the optical device and the optical device for finely adjusting the illuminance of the fragment A metal ring with a stop screw by which the instrument can be mounted on the mirror plate of a microscope. A sketch of this test apparatus is shown in Figure 65. (Related instrument: lux meter)

From a line diagram thus traced, a fairly complete idea of the degree of electrolysis of the paint can be derived. You can use a measuring ruler or a micrometer eyepiece to determine the size of the pigment particles that have been measured. Because all the colors produced before have a certain matching: ensure that it is easy to compare the obtained line diagram with the determined standard. Relatively small, because all the colors produced before have a certain matching: ensure that it is easy to compare the obtained line diagram with the determined standard.

If it is desired to obtain a colored map, the aggregates or particles in the wheel can be painted with a similar color on paper, and then the remaining blanks can be painted with a suitable color visible under the microscope (. See Figure 71).

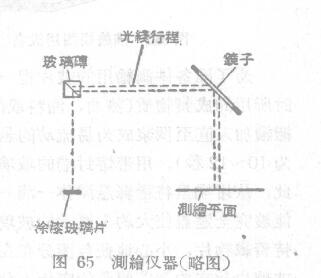

A schematic diagram of the assembled measuring instrument (under projected and reflected light structures) and Detector is shown in Fig. 66,

In order to prepare the glass slides for testing, dilute a certain amount (5-10 grams) of film-forming substances (cooked oil, oil into varnish) in the crucible; continue to add the film-forming substances Until the thick pack becomes the most buoyant body that is easy to flow (viscosity is 10-12 seconds according to the B3-4 viscometer), use a broken glass with a port seal and start to prepare the glass slides carefully. In this method, pour the diluted suspension drop by drop on one end of the observation piece, so that it can completely cover the broken glass of about 1 cm (see 462 and 671), then hold the slide in your hand, and use it carefully The color paint is distributed on the surface of the slide as large as possible, and then the glass head is placed on the seat plate with an inclination angle of about 30° to let the excess paint flow down.

A part of the most dispersed color paint sinks on the upper part of the glass sheet, while the finely dispersed part flows down. In order to measure the grinding fineness, only the dispersed part of the color paint needs to be paid attention to. Therefore, it is necessary to observe the surface of the glass slide under the microscope. The upper part is about 1.5 meters long and 2 cm wide.

In order to determine the average degree of dispersion of the color paint, the middle of the fragment must be observed. Put the fragment of the paint on the microscope stage, observe at 10~12 inches, and draw the largest aggregate in each spot and Group l its size. Compared with the color speed grinding fineness standard, it is easier to measure the fineness on the millimeter grid paper, because it can measure the size of the grid in advance under the condition of any multiple of the microscope , so that the size of the aggregates drawn can be obtained through l1. For example, when the microscope is magnified by 150 times, 1 mm corresponds to 6.5 basis meters. When the microscope is magnified by 600 times, 1 basis meter The diameter is about 2.1 mm, and it is easiest to observe the paint fragments under the microscope under reflected light. Because in this case, the shape of the aggregate is smaller than that under the incident light. It is more clear and more obvious. In addition, it is not only easy to measure the size of the particles under reflected light, but also easy to determine that they belong to the next component of the paint.

When measuring under reflected light, it is necessary to place a whole piece of black paper (for light color paint) or white paper (for dark or black color speed) under the paint-removing glass slide, and the light should hit the glass slide and the display. Between the lens and the objective lens, some color paints are shown on Figure 7u when they are ground and magnified 150 times by photomicrographs, and Figure 71 shows the test chart of mixing speed as an example. (Related instrument: grinding machine)