"No sticky dust" drying speed by finger touch test

The most common method of determining how fast a paint material will dry "cling-free" is to test the dryness of the surface by feeling it with your fingers. Test once every 15 minutes with the finger touch test method, and then test every half an hour, and determine the dryness of the paint film by subjective feeling. When the finger is lightly pressed on the paint film without leaving any finger marks, it can be considered that the surface of the paint film is dust-free. However, the dust-free paint film will also show serious "stickiness". When the finger is pressed on the paint film, it will leave very clear marks. (Related instrument: drying time point Tester)

Determination of "dust free" drying speed by dew appearance method

The method of measuring the drying speed of "dust free" by finger touch is based on subjective feeling alone.

Very good results can be obtained with the simple method of measuring the "dust free" drying rate proposed by CB Yakubovich and BC Stokoff. This method is primarily suitable for determining the "clean" drying rate of oil-based paints and varnishes. This method is based on the relationship between the condensation of water vapor (formation of dew balls) and the hydrophilicity and hydrophobia of the surface'6. If you take a breath on the dried paint film, it will leave a dew mist on the surface, and as a result, the paint surface will become bird-like (dull). The dew that remains on the dry paint film evaporates quickly. If the colored paint film is not dry or not completely "dust-free", no dew can remain on the paint film. If you take a breath on the "dust-free" paint film that has just started the drying process, the dew will only remain on individual areas of the paint film surface and individual matt (dark) spots will appear there. As the paint As the film continues to dry, the dull spots on the surface will continue to expand until finally the entire surface of the paint film becomes dull after taking a breath. (Related instruments: Adhesion Tester)

In order to measure the drying rate, a paint film must be applied to a glass plate. Then after 3 to 4 hours, breathe on the painted surface for one second · gold (the broken glass plate is placed about 10 cm away from the mouth). If no dull (relevant instrument: gloss meter) spots appear on the painted surface at this time, it indicates that the colored paint film has not yet dried to the point of "dust-free". Test every half an hour to see when dull spots appear. The appearance of individual matt spots on the surface of the paint film indicates that the "dust free" drying process is nearing completion. From then on, the test is carried out every 10 cents. If the entire surface becomes dull after one breath, the paint film can be considered to have dried "dust-free".

According to the method of Yakubovich and Stokoff, the "non-sticky" drying speed of paint materials can be measured with an accuracy of several minutes.

Determination of "non-stick" drying speed with fine sand

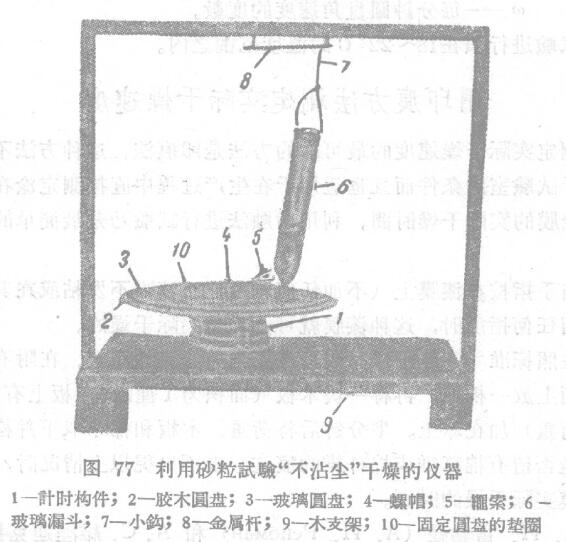

The principle of some known methods for the determination of the drying of paint molds with fine sand, the principle of some known methods for the determination of the drying of paint molds with fine sand, the researchers proposed a simple instrument for the determination of "dust free" drying (Fig. 77)

The components of this instrument are as follows: a needle hour component 1, on which a bakelite enclosure 2 (thickness 4 mm, diameter 320 mm) is sleeved. A glass disc 3 (thickness 3 mm, diameter 280 mm) is provided with a coating film on the disc. Discs 2 and 3 placed on the shaft of the timing member are tightened by nut 4 . The bottom of glass funnel f6 (high 120 millimeters, 40 millimeters of upper hole inner diameters, 3 millimeters of lower hole inner diameters) is borrowed rope 5 and connects certain distance and is fixed on the nut 4 simultaneously.

The distance from the lower hole of the funnel 6 to the glass dish 3 with the coating film is 4 to 5 millimeters. The top of glass funnel 6 is fixed on the metal rod 8 with small hook 7, and this metal rod is to hang on the wooden support 9 again. The sand funnel is covered with a lid.

The quartz sand filled with the funnel needs to be pre-dried and sieved once on the two sieves of 6400 holes/cm2 and 10000 holes/cm2; the remaining sand sieved on the last sieve is reused . Dry for testing.

As the disks 2 and 3 rotate, the sand funnel 6 is directed towards the frame 4, leaving swirling traces of sand grains on the painted glass disks.

Of all the measurements it is most convenient to calculate in degrees of circumference. The disk rotates at an angular velocity of 0.65° to 0-86° in 1 minute. The disc rotation speed needs to be constant in each trial. Apply the paint material to the glass dish 3. The disc 3 with the coated film is placed on the Bakelite disc 2; the grit is then removed on the coated film. The next day, remove the painted disc from the instrument and remove the grit with a soft brush or bristle brush. The time at which the sand particles stop adhering to the coating film is determined according to the traces of sand particles left by the soft brush or flat brush and the rotation speed of the glass disc 2.