A reliable method of determining the actual drying rate is the blot method. This method is not only applicable to the conditions of the laboratory, but also suitable for directly measuring the actual drying time of the coating film applied to the utensils during the production process. Testing by finger touch is a simple test method.

A paint film is considered to be practically dry when a finger is placed on it (without applying any pressure) and the film does not become sticky or leave any finger marks on its surface. According to standard 32. The actual dry operation time can be measured according to the following methods. Put a cotton ball on the surface of the coated film, and then add a wooden board (with an area of 1 cm 2 and a load of 200 grams) on the ball. After half of the gold, remove the load, wooden board and cotton ball to check whether there are traces of cotton or cotton fiber on the coating film. When the above conditions do not occur, it indicates the moment when the coating film is actually dry.

Leibman and Wiman Diktova proposed a method based on the different degrees of adhesion of filter paper to the surface of the coating film. The test is carried out under the pressure of about 6 kg and the test time is 30 seconds. The pressure is from a metal die. This method gives satisfactory results when testing most paint materials.

When testing various paint materials, CB Yakubovich and TH Vorogushin used the imprint method that has achieved very good results. For example, with this method, not only the actual drying time of the paint film can be measured, but also the beginning stages of different drying processes can be observed.

For the determination, a steel cylinder whose bottom is in the shape of a truncated cone (Fig. 78) can be used. On this base (diameter 1,13 cm) a soft rubber ring with a smooth surface is attached. The diameter of the ring should be equal to the diameter of the bottom, and its thickness should be 1.5 to 2 mm. The bearing area is 1 cm2. The total cylinder weight is 200 grams.

For the determination, a steel cylinder whose bottom is in the shape of a truncated cone (Fig. 78) can be used. On this base (diameter 1,13 cm) a soft rubber ring with a smooth surface is attached. The diameter of the ring should be equal to the diameter of the bottom, and its thickness should be 1.5 to 2 mm. The bearing area is 1 cm2. The total cylinder weight is 200 grams.

When conducting the test, ordinary typing carbon paper should be used. In order to obtain reproducible results, each test needs to use the same standard carbon paper. Therefore, it is recommended to use carbon paper that meets the requirements of T0CT489-41.

The test should be carried out at a temperature of 20° (± 2°) C and a relative air humidity of 60-65%. The dried paint material is pre-dried at an appropriate temperature in a thermostat. (Related instrument: oven)

In order to measure the dry operation time, put the sample panel with the tested coating film (the thickness of the paint film is 0.02~0.025mm) on the surface at the horizontal position, and then place a strip of carbon paper with a width of 5 mm on the paint film. face down. Carefully place the cylinder onto the carbon paper and leave on the paper for 30 seconds. (Related instruments: paint Film Thickness Gauge)

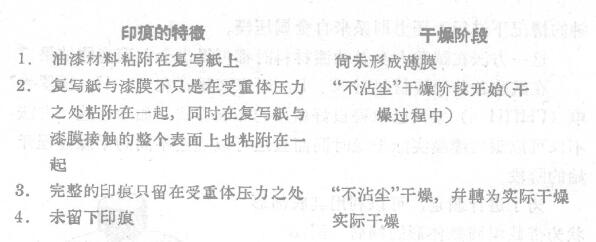

Afterwards, remove the cylinder, take off the paper strip, and draw conclusions about the degree of dryness of the paint film based on the characteristics of the imprint left by the carbon paper on the paint film. These tests need to be carried out at certain time intervals stipulated by the technical conditions.

The placement of the cylinder and the location of the impression shall be in a new and different part of the paint film in each test, but not closer than 2 cm from the edge of the panel. 4 consecutive stages can be marked when determining the degree of dryness (see Figure 79)

During the test, where the coating film is close to the impression, the test time should be recorded with water as appropriate.

Figure 79 shows the different stages of dry working of enamel. The "non-sticky dust" dry operation process starts after 15 minutes, and the "non-sticky dust" dry operation can be achieved after 1.5 hours, and the actual drying can be achieved after another 30 hours. (Related instruments: drying time Tester)

When determining the drying speed according to the imprint method, the concept of actual dry operation can be clarified as follows. Actual drying of paint material

(T) should be understood as the time from the time when the paint material is applied until the formed film (with a thickness of 0.020-0.025 mm) does not leave a colored imprint of the carbon paper after the pressurization (the area of the bottom of the pressurized weight is 1 cm) 2. The weight is 200 grams, the time is 30 seconds, the test temperature is 20° (± 2°) C, and the relative air humidity is 60~65%). (Related instruments: constant temperature and humidity Test Chamber)

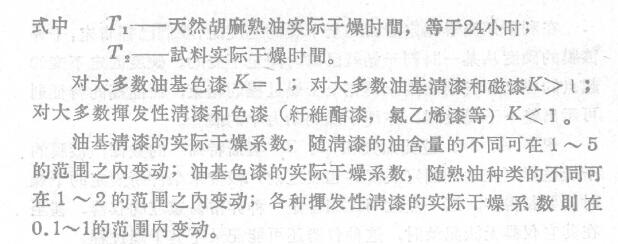

If the actual dry operation time of the paint film made of natural flax cooked oil is used as a comparison value (T1=24 hours), the actual dry operation coefficients of various paint materials can be calculated