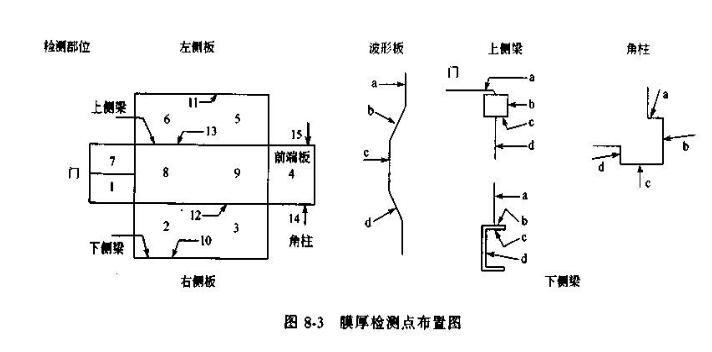

According to the characteristics of international standard container business and container coating supply, when each batch of containers is put into production, the container manufacturer and coating supplier will simultaneously test the film thickness. Although, in recent years, individual container factories have relaxed this work, and incidents of rejection by owners due to problems in film thickness and quality have also occurred, but the vast majority of container factories have taken serious measures to ensure product quality and control paint consumption. To carry out a series of quality management work such as general thickness inspection, data collation, analysis, and production guidance, the technical department of the container factory should design a special paint Film Thickness Gauge. In order to truly reflect the quality of the film thickness and make the detection value of the film thickness distribution uniform and representative, the number and arrangement of the measuring points are specified in each paint film thickness measurement table, especially It is the inspection point for special structural parts such as left and right side panels, front-end panels, corner columns, upper and lower inverted beams, bottom beams, and forklift grooves. It is shown in a schematic diagram. The focus of random testing by technical service personnel and box owners. According to past experience, the inspection points for each 20ft container are about 180-200 points, and the density of detection points is 1.2 points/㎡. At the same time, it is necessary to implement full-time quality inspectors, strengthen the responsibility of the inspectors, and eliminate the film thickness according to 2% of the number of production boxes in each shift. (Related Instruments: Thickness Gauge)

The inspector shall enter all the values of the film thickness inspection machine into the specified paint film table, file and record the order of the box number, and submit it to the box owner for random inspection if necessary.

It is worth mentioning here that the paint breakage thickness measurement table of the container factory should also include the film thickness of the structural parts at the bottom of the container. The film thickness of the asphalt method of the part. There are many dead angles at the bottom of the box, and the film thickness inspection should be particularly careful (see Figure 8-3).

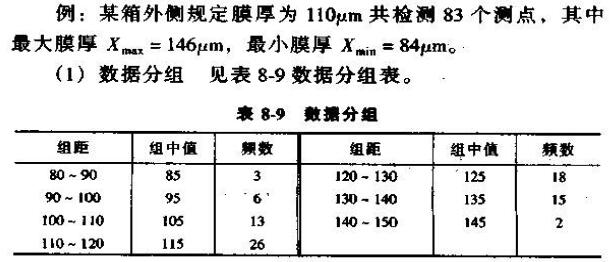

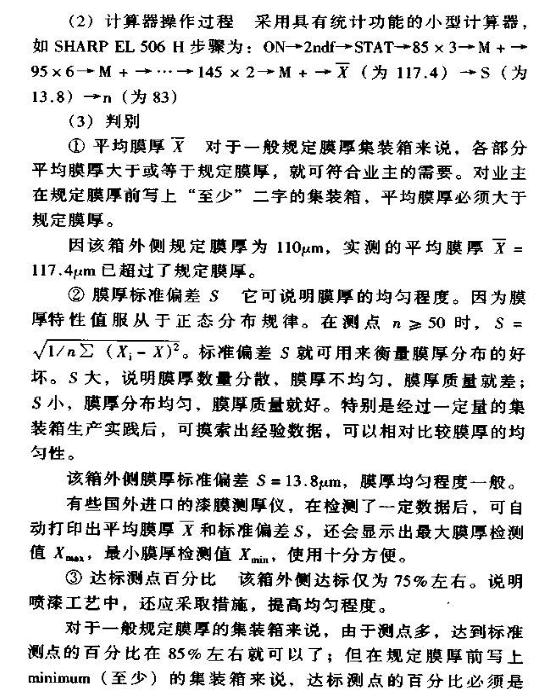

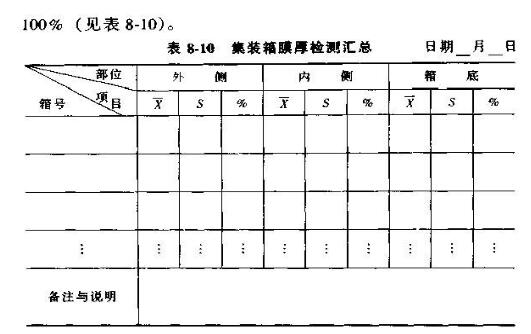

In order to judge whether the film thickness quality index meets the requirements, summarizing and sorting out the film thickness test data is the key to the same problem. According to the author's actual experience, it is divided into three parts, the inner side, the outer side and the bottom of the container. Statistical function, respectively calculate three film thickness quality indicators, now an example.

From the analysis of the film thickness quality index, the container manufacturer can grasp the initiative in coating management. If the film thickness is insufficient, the coating quality will be affected, and some construction conditions need to be changed to take necessary measures. Thickness will increase the consumption of containerized coatings, and will also "prescribe the right medicine" to reduce the cost of box manufacturing, and check the quality of the film thickness of the box owner and the coating technology service provider. It can also be used as a check, which is beneficial to the integration of the three parties Relationship. (Related Instruments: Coating Thickness Gauge)

In addition, regarding the travel contract of the container coating supplier, the technical service personnel dispatched to the front line of the workshop insist on understanding the unpacking quality, testing the film thickness, and reporting to the container owner or container inspection company in time, Table 8-11 and Figure 8- 3 is the film thickness inspection table and the distribution map of film thickness inspection points of Shanghai Customs Materials Co., Ltd. In contrast, their detection points have been reduced a lot.

In the container industry, sales owners or container inspection companies generally entrust technical service personnel of coating manufacturers to undertake coating quality inspection and film thickness testing, listen to their reports, and coordinate container factories and paint factories to ensure coating quality. Relationship.