The interlayer bonding force strength Tester also has important application value in the manufacture and use of cigarette packs. Cigarette case is a common packaging box, which is used to package various tobacco products such as cigarettes, and has the functions of protecting products, convenient carrying and displaying products. The internal bonding strength Tester can help manufacturers and users understand the internal bonding strength of cigarette packs, thereby improving the quality and reliability of cigarette packs.

In the application of cigarette boxes, the inner bond Tester can be used to test the bonding strength between different layers, as well as the overall bonding strength of the cigarette box. By testing the internal bonding strength of different processes and raw materials, manufacturers can determine the best production process and raw materials to produce better cigarette packs. In addition, the internal bonding strength Tester can also help manufacturers and users understand the internal bonding strength of the cigarette pack under different humidity and temperature conditions, so as to determine its scope of application and service life.

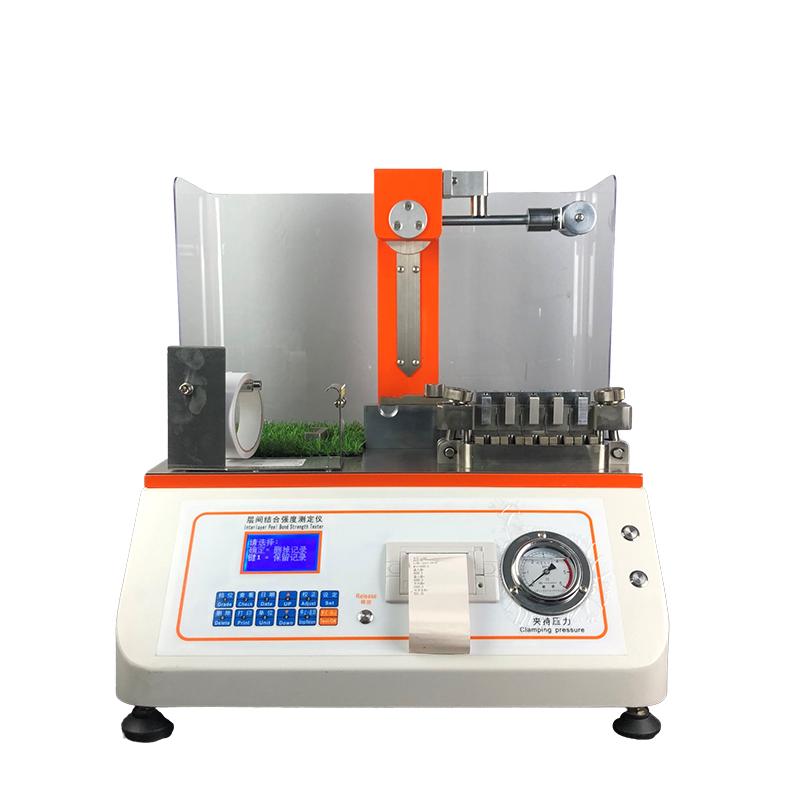

During the test, similar to testing electrical paperboard, electrical insulating paperboard, paper tube, yarn tube paper, kraft paper, gray cardboard, white board paper and packaging boxes, it is necessary to prepare test samples first, place them on the test bench, and start the test after adjusting the test parameters. After the test is completed, the internal bonding strength of the cigarette pack can be evaluated based on the test results, thereby improving the quality and reliability of the product.

Specifically, in the internal binding force test of the cigarette pack, the following steps can be followed:

Prepare test samples: cut a sample of a certain size from the cigarette pack, generally rectangular or square, and the size and shape should meet the test requirements.

Install the test sample: place the test sample on the test table of the internal adhesion Tester, align and clamp it to ensure that the sample is fixed.

Adjust test parameters: According to the test requirements, adjust the test parameters of the internal binding force Tester, such as test speed, pressure range, etc.

Start the test: Start the internal binding force Tester and start the test. During the test, the instrument applies gradually increasing pressure until separation occurs between the different layers. During the test, the pressure value and test time can be recorded for subsequent analysis.

Analysis of test results: After the test is completed, the internal bonding strength of the cigarette pack can be evaluated based on the test results. If the test results meet the requirements, the internal bonding strength of the cigarette pack can be guaranteed, thereby improving the quality and reliability of the product.

NBCHAO reminds you: when testing the internal binding force of cigarette packs, it is necessary to pay attention to the size and shape of the test sample, as well as the selection of test parameters. Different types of cigarette cases usually have different structures and sizes, and it is necessary to select appropriate test methods and test parameters during testing to ensure the accuracy and reliability of test results.

In short, the internal binding force Tester plays an important role in the manufacture and use of cigarette boxes, which can help manufacturers and users understand the quality and reliability of cigarette boxes, and improve the service life and safety of products. When testing, it is necessary to pay attention to the use of the instrument and the adjustment of the test parameters to ensure the accuracy and reliability of the test results.