Silicon oxide is a commonly used inorganic material with excellent high temperature resistance, corrosion resistance and insulating properties. However, silicon oxide may age, degrade and degrade under prolonged exposure to UV radiation and other environmental factors.

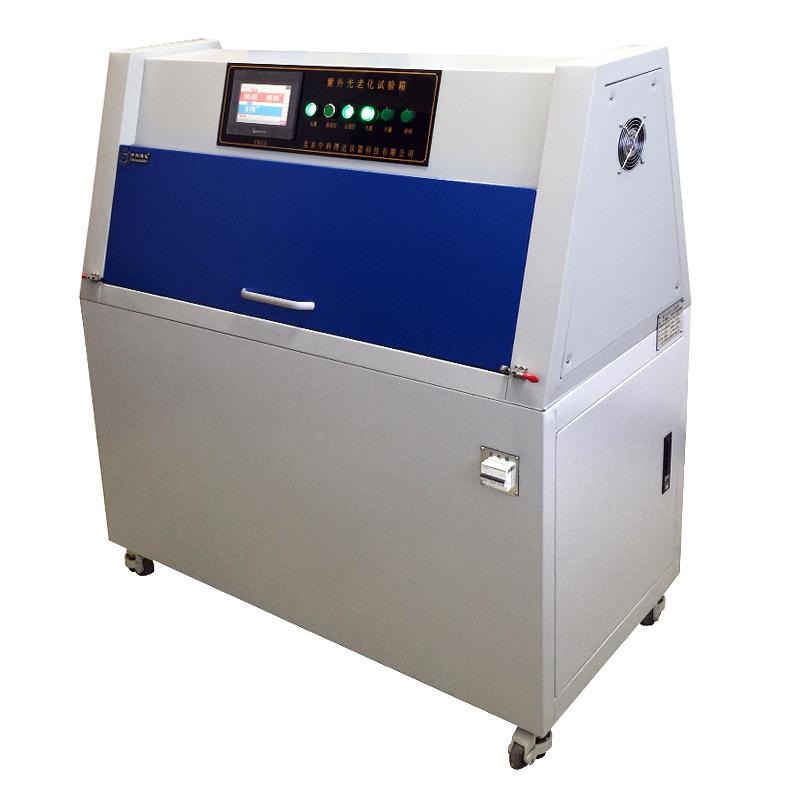

The UV aging Test Chamber can simulate the UV radiation and climatic conditions in the real environment, and evaluate the performance by accelerating the aging process of silicon oxide.

How to operate

The following is how to operate the UV aging Test Chamber in the application of silicon oxide:

Material selection and preparation: Select the silica material that meets the requirements. Silicon oxide samples of different purity, shape and size can be selected as required.

Set test conditions: According to the test requirements, determine the parameters such as UV radiation source, temperature, humidity and radiation time in the Test Chamber. These conditions should be able to simulate real UV radiation and climatic conditions, such as sunlight exposure, high temperature, humidity, etc.

Mounting the sample: Place the silica sample on the sample table of the Test Chamber to ensure that the surface of the sample is exposed to UV light sources. Samples of different shapes and sizes can be selected, such as sheet, block or tubular.

Start the test: Start the UV aging Test Chamber and expose the sample to simulated UV radiation. According to the set test conditions, the radiation is for a certain period of time. At the same time, the damp-heat cycle can be selectively performed to simulate the real climate environment.

Monitoring and recording: Regularly monitor and record the performance changes of silicon oxide samples. Appropriate instruments and equipment, such as material testing instruments, electrical performance testing instruments, etc., can be used to measure and record the physical properties, chemical properties and electrical properties of silicon oxide.

Evaluation results: According to the test data and evaluation indicators, analyze the aging degree and performance changes of silica samples. Compare the differences between different test samples to evaluate the durability, stability and service life of silica.

Industry standard

In the UV aging test of silicon oxide, the following industry standards can be referred to:

ASTM C1442 is a standard published by the American Society for Testing and Materials (ASTM) for the testing of thin-film protective coatings, including silicon oxide films. Although the standard is primarily for thin-film coatings, some of these test methods are also applicable to UV burn-in testing of silicon oxide.

ISO 11431 is a standard published by the international standards organization (ISO) for the determination of glass transition temperature by differential scanning calorimetry. Although the standard is primarily aimed at glass containers, some of the test methods can also be applied to the performance evaluation of silica.

Specific application

Specific application cases include but are not limited to the following areas:

Semiconductor Industry: Silicon oxide has a wide range of applications in semiconductor manufacturing, such as manufacturing insulating layers, isolation layers, and through-hole filling. UV aging testing can be used to evaluate the durability and stability of silicon oxide under prolonged exposure to UV rays and other environmental factors, ensuring its reliability and performance in semiconductor equipment.

Optics and optoelectronics industry: Silicon oxide is used in optical coating, optical fiber manufacturing, optical device and optoelectronic device manufacturing, etc. UV aging testing can be used to evaluate the weather resistance and stability of silicon oxide in optical and optoelectronic applications, ensuring its long-term performance and reliability.

Glass Industry: Silica is used in the glass industry as a glass additive and glass coating material. UV aging testing can be used to evaluate the stability and weather resistance of silica in glass, ensuring the performance and durability of glass products in indoor and outdoor environments.

Chemistry and materials: Silica is used as a catalyst, filler and coating material in chemical and materials research. UV aging testing can be used to assess the durability and stability of silica in chemical and materials applications, ensuring its performance and reliability under a variety of environmental conditions.

These use cases illustrate the importance of UV aging chambers in the testing of silicon oxides, helping manufacturers and users select suitable silicon oxide materials and ensuring their durability and performance requirements in various industries.