The laboratory ultrasonic cleaner is a device that uses ultrasonic technology for cleaning. It uses the principle of bursting tiny bubbles generated by high-frequency acoustic vibrations in liquids to clean surfaces and tiny pores in an efficient and non-contact manner.

COMPONENT STRUCTURE

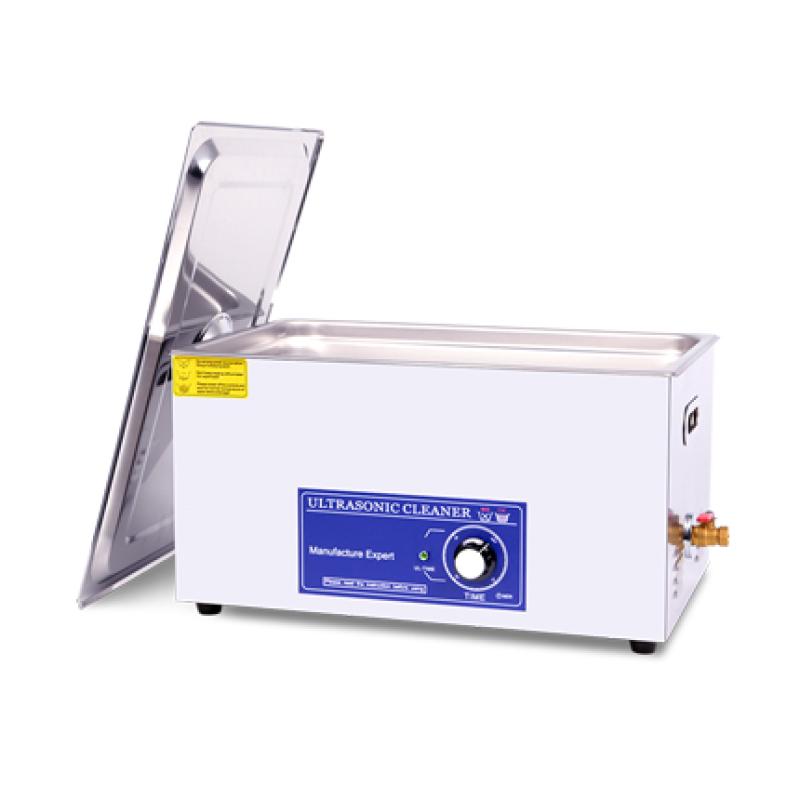

Cleaning tank: Used to hold objects to be cleaned and cleaning fluids. Usually made of corrosion-resistant materials such as stainless steel, with a certain size and volume.

Ultrasonic generator: A device that generates high-frequency acoustic vibration. It converts electrical energy into mechanical vibration and transmits the vibration to the cleaning liquid in the cleaning tank through a sensor.

Ultrasonic transducer: A device that converts electrical energy into acoustic vibration. It converts the high-frequency electrical energy generated by the ultrasonic generator into acoustic energy and transmits it to the cleaning liquid in the cleaning tank.

Control panel: used to set and control the parameters of the cleaning machine, such as cleaning time, ultrasonic power, etc. Through the control panel, the user can adjust the cleaning process as needed.

How it works

When using a laboratory ultrasonic cleaning machine, the object to be cleaned is first placed in the cleaning tank, and then an appropriate amount of cleaning liquid is added. After starting the cleaning machine, the ultrasonic generator will generate high-frequency acoustic vibrations, which are transmitted to the surface of the object and small pores through the liquid. These acoustic vibrations form tiny bubbles in the liquid, and the bubbles produce a violent impact force in the process of expansion and contraction, thereby stripping dirt and contaminants from the surface and pores of the object. The chemical composition in the cleaning liquid can also assist in the removal of dirt.

SCOPE OF APPLICATION

Laboratory ultrasonic cleaning machines are widely used in laboratory, medical, electronic, optical and other fields, for cleaning various laboratory instruments, glassware, metal parts, electronic components, etc. It has the characteristics of high efficiency, speed, non-destructive and non-polluting, and can thoroughly clean the surface and small pores of objects, improving the efficiency and quality of experiments and production processes.

DEVICE TYPE

Laboratory ultrasonic cleaners can be classified according to their functions and application fields. Here are some common types:

Desktop Ultrasonic Cleaners: This type of cleaner is suitable for small laboratories or occasions where smaller objects need to be cleaned. They usually have a smaller wash tank capacity and power and are suitable for handling small batches of laboratory equipment and samples.

Industrial type ultrasonic cleaning machine: This type of cleaning machine is suitable for industrial production environments and handles large quantities of object cleaning. They usually have a large cleaning tank capacity and high power, capable of handling larger size and weight objects.

Medical type ultrasonic cleaning machine: This type of cleaning machine is specially designed for the medical industry and is used to clean medical apparatus, utensils and equipment. They usually have special cleaning procedures and functions to ensure thorough removal of contaminants and microorganisms.

Special material cleaning machines: Some ultrasonic cleaning machines are specially designed to handle special materials such as glass, ceramics, optics, etc. They have special cleaning fluids and parameter settings to avoid damage to these materials.

Automated ultrasonic cleaning system: This type of cleaning machine is equipped with an automated system that can carry out an automated cleaning process. They usually have automatic feeding and unloading functions, which can improve production efficiency and reduce labor input.

These types of ultrasonic cleaning machines may vary in size, power, function and application field. According to the specific needs, you can choose the suitable type and specification of ultrasonic cleaning machine. There are some differences in the application of ultrasonic cleaning machines with different powers. The following are some common application examples of ultrasonic cleaning machines with different powers:

Low power cleaning machine (generally tens of watts to hundreds of watts):

Laboratory application: used for cleaning laboratory utensils, glass ware, small reagent bottles, etc.

Electronics industry: suitable for cleaning small electronic components, circuit boards and other tiny parts.

Jewelry and eyewear industry: used to clean small items such as jewelry and eyeglass frames.

Medium power cleaning machine (generally a few hundred watts to several kilowatts):

Industrial applications: for cleaning mechanical parts, metal parts, molds, etc.

Automotive industry: suitable for cleaning automobile engine parts, nozzles, oil nozzles, etc.

Medical industry: used for cleaning medical apparatus, surgical instruments, dental instruments, etc.

High-power cleaning machine (generally several kilowatts to tens of kilowatts):

Industrial application: suitable for cleaning large mechanical parts, steel products, pipes, etc.

Aerospace industry: used to clean large objects such as aero-engine parts and aerospace parts.

Manufacturing: Suitable for cleaning large workpieces, castings, welded parts, etc.

SELECTION

The specific power should be determined according to the size, shape, material of the cleaning object and the degree of contamination that needs to be cleaned. The higher the power, the better the cleaning effect of the cleaning machine is usually, but it is also necessary to consider the tolerance of the object and the choice of cleaning liquid. Therefore, when choosing an ultrasonic cleaning machine, the appropriate power range should be selected according to the specific application needs and the characteristics of the object. When choosing a suitable ultrasonic cleaning machine, the following key factors can be considered:

Cleaning object: First, you need to determine the type, size and material of the object to be cleaned. Different objects may have different requirements for the power and capacity of the cleaning machine. In the case of large objects or large batches that need to be cleaned, it may be necessary to choose a cleaning machine with higher power and larger capacity.

Cleaning requirements: Determine the requirements and standards for cleaning. Different application scenarios may have different requirements for cleaning effect, cleaning speed, and cleaning degree. For example, the medical industry has higher requirements for the thoroughness of cleaning equipment, while the laboratory may pay more attention to the degree of purification of cleaning utensils. According to the requirements, choose the appropriate power and function.

Cleaning fluid: Choosing the right cleaning fluid is crucial to the cleaning effect. Different cleaning fluids may have different requirements for ultrasonic cleaners. For example, some special materials may require the use of specific cleaning fluids, and some application scenarios may require high temperature or special chemical composition cleaning fluids. Make sure the cleaning machine is suitable for the required cleaning fluid.

Budget and available space: Consider budget and available space. Prices and sizes of ultrasonic cleaners vary by model and feature. Choose the right model based on budget and available lab or workspace space.

User-friendliness: Consider the ease of use and ease of operation of the cleaning machine. Choosing a cleaning machine with easy setup and control, as well as cleaning process monitoring and automation, can improve work efficiency and convenience.

FAQ

Here are some common questions and answers when choosing and using a laboratory ultrasonic cleaner:

1.How to choose the power of the cleaning machine?

The power selection should be determined according to the size, shape, material of the cleaning object and the degree of contamination to be cleaned. In the case of large objects or large batches that need to be cleaned, it may be necessary to choose a cleaning machine with higher power. Generally speaking, depending on the size of the object, low power (tens of watts to hundreds of watts) is suitable for small objects, medium power (hundreds of watts to thousands of watts) is suitable for medium-sized objects, and high power (thousands of watts to tens of kilowatts) is suitable for large objects.

2.How to choose a cleaning solution?

The choice of cleaning solution should be determined according to the material and type of contamination of the cleaning object. In general, use a specially designed ultrasonic cleaning solution or choose an appropriate cleaning agent according to the cleaning requirements. Special materials or specific application fields may require the use of a specific cleaning solution. Pay attention to the composition and method of use of the cleaning solution to ensure safety and cleaning effect.

3.What do you need to pay attention to in the maintenance and maintenance of the cleaning machine?

Regular cleaning and maintenance of the cleaning machine is the key to maintaining its performance and life. After the cleaning machine is used, the tank and drainage system should be cleaned to prevent the residual cleaning fluid and the accumulation of contaminants. Regularly check that the ultrasonic transducer and other key components are working properly and maintain them according to the manufacturer's instructions. Follow safe operating procedures to avoid damage to the cleaning tank and ultrasonic generator.

4.Is ultrasonic cleaning suitable for all objects?

Ultrasonic cleaning is suitable for many different types of objects, including metals, glass, plastics, ceramics, etc. However, certain materials or objects may be more sensitive to ultrasonic vibrations, so careful selection of appropriate cleaning parameters and cleaning fluids is required. For special materials or sensitive objects, it is best to test them before use to ensure that they are resistant to the ultrasonic cleaning process.

5.How to verify the effect of ultrasonic cleaning?

After cleaning is completed, the cleaning effect can be verified using naked eye observation, microscopy or other detection methods. Check whether the surface of the object is clean and free of residues or contaminants. Sometimes chemical indicators or testing instruments can also be used to verify the cleaning effect, such as surface tensIon Meters, residual contamination tests, etc.

Parameter example

Below is a table listing common parameters to describe the characteristics of laboratory ultrasonic cleaners:

| PARAMETER | DESCRIBE |

| Cleaning tank capacity | The capacity of the cleaning tank, usually in liters or gallons |

| power | The power of a cleaning machine, usually in watts (W) |

| Cleaning frequency | The frequency of ultrasonic vibration, usually in kilohertz (kHz) |

| Cleaning fluid type | Applicable cleaning fluid type such as water, solvent or special cleaning agent, etc |

| Cleaning time | Time required for a single cleaning cycle |

| temperature control | Control method of cleaning tank temperature, such as constant temperature control or adjustable temperature range |

| Operation interface | The type of operation interface of the cleaning machine, such as touch screen or button control |

| Automation function | Whether it has automation functions, such as automatic feeding, automatic drainage, etc |

| Ultrasonic power regulation | Whether it has the function of adjusting the ultrasonic power to adapt to different cleaning needs |

| safety function | Whether it has safety functions, such as overheating protection, ultrasonic generator fault protection, etc |

| External dimensions | External dimensions of the washer to assess required workspace and installation requirements |

| material | The main material of the cleaning machine, such as stainless steel, plastic, etc |

| Power Requirements | Power requirements for the cleaning machine, including voltage, frequency and current, etc |

| Noise level | The noise level generated by the cleaning machine during operation |

Please note that specific ultrasonic cleaners may have different parameters and specifications, depending on different manufacturers and models. The parameters listed in the table above can help you compare and choose the ultrasonic cleaner that suits your needs.