Hull Roughness Measuring Instrument/Universal Surface Photometer

The Hull Roughness Meter/Universal Surface Photometer TQC has made further improvements in the detection of hull roughness.

Exceeding industry standards, it adopts easy-to-operate 4-way buttons, graphical representation, multi-batch data storage and test reports in EXCEL format. The entire system is housed in a small waterproof case that fits in carry-on luggage for overseas travel.

The importance of surface roughness control in terms of ship operating costs cannot be overemphasized. The increase in hull roughness is mainly due to corrosion, pitting, waves, mechanical damage, dry spraying or biological fouling. Proper maintenance and correct application of high-end antifouling paint can effectively reduce hydrodynamic effects, thereby saving fuel consumption and CO2 emissions to a large extent. Hull roughness is checked during the ship's entry and exit. The Hull Roughness Measuring Instrument is an instrument used to measure the AHR value (average roughness) of a seagoing hull. AH R is the "average" of all hull roughness readings and is a measurement related to ship performance.

Multi-Surface Measurement

A new generation of adjustable RT parameters for all common surface measurements such as windmill blades, aircraft wings, etc.

features

Easy-to-operate 4-way button

Multi-batch data storage

Test report in Excel format

sturdy case

Suitable for general surface measurement

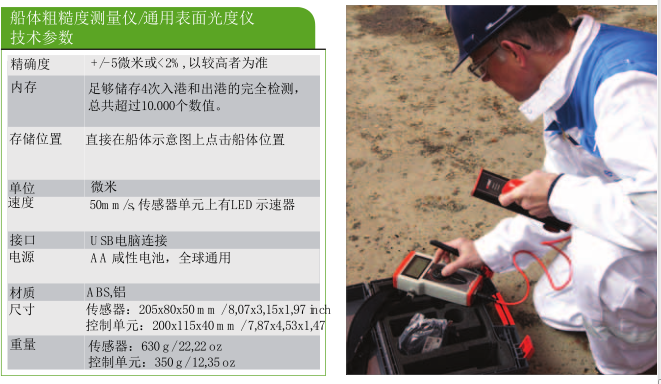

TQC Hull Roughness Measuring Instrument consists of a control unit and a sensor unit. The Hull Roughness Gauge control unit can be operated with one hand, and the 4-way button allows intuitive operation of the menus on the large screen. The neck strap frees the user's hands when necessary.

The sensor is equipped with three non-skid wheels and a carbide stylus, which moves horizontally on the hull to collect a series of detection values. The sensor is equipped with a set of LED lights to indicate the status of the instrument, so it can be operated without looking at the control unit.

The roughness measuring instrument automatically calculates and stores the data, time/date, position of each set of data, and average roughness in the control unit. Use the matching USB cable and software to quickly import the test report into the EXCEL table. At the same time, company LOGO and/or detailed information can be added to the report to make the report more personalized.