This article is a question about "The Operation and Design Analysis of Telling Disperser" written by scholar Fu Dongmei. It mainly describes the role played by high-speed dispersers in the paper industry from the wetting and dispersion operations of high-speed dispersers.

The high-speed disperser has been widely used in the production of heavy calcium carbonate for papermaking. Whether its operation and design are correct or not will directly affect the dispersion effect. The production capacity of the high-speed disperser depends on the ability of wetting dry calcium carbonate powder, the ability of dispersing large calcium carbonate particles and the ability of circulating calcium carbonate slurry. These three capabilities are often interrelated but independent of each other, so it is necessary to balance these three factors to design and select the dispersed impeller. The calcium carbonate slurry has a good wetting effect if it is in a vortex state; it has a good dispersion effect if it is in a laminar flow state. Therefore, the high-speed dispersing operation should be divided into two steps: first wetting operation, and then dispersing operation.

Wetting Operation of High Speed Disperser

At this time, the impeller stirring shaft is placed in the center of the tank, and the height and speed of the impeller should be adjusted to make the slurry center on the shaft and form a vortex. The vortex of the material should not be lower than the impeller, otherwise air will be mixed in and the dispersion efficiency will be reduced.

Add dry calcium carbonate powder directly to the vortex, and add from fast to slow. Be careful not to add to the shaft and tank wall. In order to maintain the vortex of the material, the viscosity of the slurry will increase correspondingly with the increase of the material. At this time, it is recommended to increase the impeller speed intermittently. position and increase the speed. Feeding at low speed can significantly reduce dust.

Dispersing operation of high-speed dispersing machine

Dispersion operation should adopt high speed, after adding dry calcium carbonate powder for a few minutes, when there is no dry powder floating on the slurry surface, offset the stirring shaft between the tank and the side of the tank to improve the dispersion efficiency and eliminate the dead angle. shaft offset though

Although it will increase the energy consumption, the dispersion efficiency can be increased by 25% to 50%. The other purpose of the axis offset is to prevent the slurry from viscous circular motion, so as to avoid poor circulation of the slurry and excessive temperature rise of the material. and mixed with air.

The speed of the impeller is generally recommended to be the linear speed of the blade 20-60m/s. Whether the material can be circulated is very important to a good dispersion effect. Even with the same speed, the effect of the small impeller is worse than that of the large impeller. The reason is that the circulation is not complete, and the external material cannot be circulated to the dispersion area of the impeller. Enlarging the diameter of the impeller can improve the material dispersion. cycle status. This can also be achieved when reducing the viscosity of the slurry.

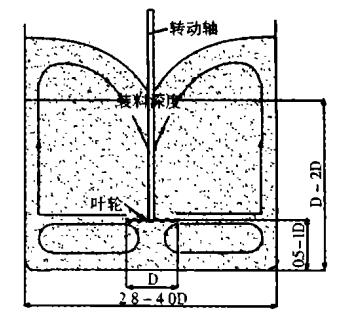

Generally speaking, when the diameter of the impeller and the tank is 1/3 to 1/4, and the distance from the impeller to the bottom of the tank is 1/2 to 1D (D-the diameter of the impeller), the circulation effect is better. The bottom of the tank is preferably dish-shaped to reduce dead ends. The relationship between impeller and charging size is shown in Figure 1

The relationship between the impeller of the high-speed disperser and the size of the charge

The optimal rotational speed of the dispersing impeller is about 27m/s of the blade linear velocity. After adding a sufficient amount of dry powder, the viscosity of calcium carbonate can reach 8-10Pa·s. Stirring time should be as short as possible, if the humidity is too high, stop the machine. To control humidity rise,

Intermittent operation is possible. The dispersing time of the high-speed disperser is not very long, generally 10-20 minutes can achieve the goal, the viscosity will drop to 0.15-0.3Pa·s, and the continuous operation will have little effect on the dispersion, or even useless. Since the wetting operation and dispersion require different speeds and different impeller heights, a high-speed disperser with more than two speeds and a hydraulic quick lifting device is more convenient and more applicable.

Author: Fu Dongmei Mudanjiang Shunda Calcium Carbide Co., Ltd. (157009)

Topic: "Operation and Design Analysis of High Speed Disperser"

Excerpt: 2003 "Heilongjiang Paper"