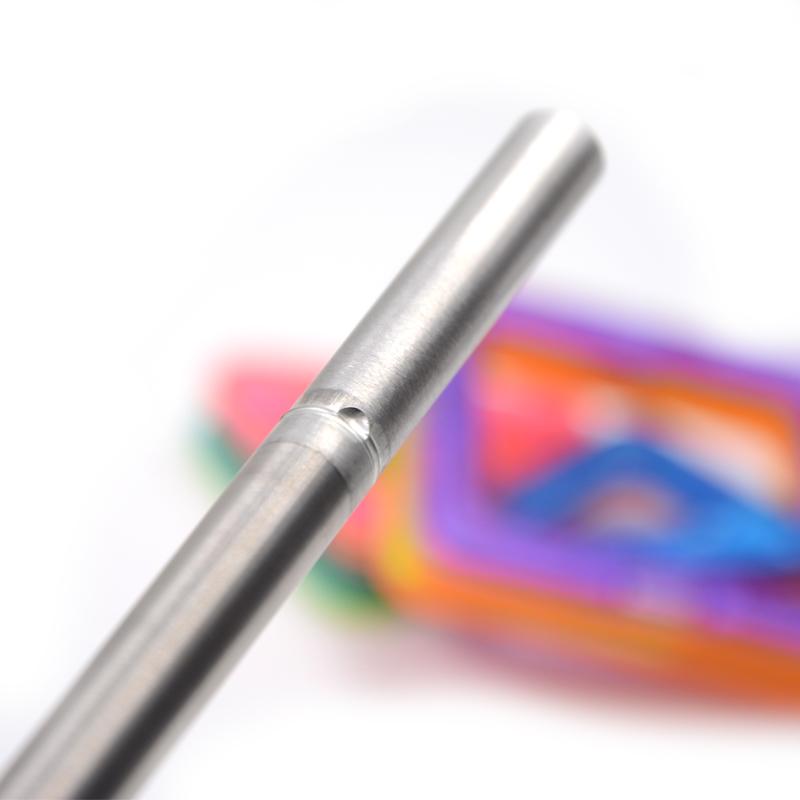

Coating rods are a laboratory tool used to uniformly coat liquid materials such as paints, inks, glues, adhesives, etc. on the surface of various materials. Their design and construction can affect the thickness, uniformity and quality of the coating, so they play a key role in the coating process. Coating rods are usually made of stainless steel, plastic and other materials, with different groove shapes and sizes to meet different coating needs.

Type of coating rod

There are various types of coating rods, which can be selected according to the purpose and requirements of the coating. For example, the wire-wound coating rod has a filament winding line, which can control the distribution of the coating material during the coating process; the extrusion coating rod is squeezed to form grooves to achieve coating; the molding coating rod adopts an integrated molding process in the manufacturing process, and different groove shapes can be customized to achieve precise coating effects with different fluids.

Coating rods are widely used in laboratory coating preparation, sample preparation, coating research and other fields. By selecting the right coating rod, researchers can explore the characteristics of different coating techniques, coating materials, and precisely control the thickness and uniformity of the coating during the experiment.

Application field

Coating rods are widely used in different types of coating processes such as coatings, inks, glues, adhesives, etc., covering many fields, such as paper printing, packaging, electronics, pharmaceuticals, cosmetics, etc.

Material and groove design: The material and groove design of the coating rod are critical to the coating effect. Coating rods of different materials and groove shapes can produce different coating effects, affecting the uniformity, quality and thickness of the coating.

Coating thickness control: The coating rod can be used to control the thickness of the coating during the preparation of the coating film in the laboratory. Coating layers of different thicknesses can be realized by adjusting the pressure of the coating rod, the coating speed and the fluidity of the coating material.

Experimental design and research: In coating research, coating rods can be used as an important experimental tool. Researchers can explore the optimal parameters of the coating process and optimize the coating technology by testing the coating effect of different coating rods and different coating conditions.

Coating uniformity and quality: The use of the coating rod can effectively control the uniformity of the coating and avoid uneven conditions during the coating process. This is essential for the preparation of high-quality coating samples.

Research and innovation: For the needs of different application fields, the design and manufacture of coating rods are also constantly innovating. For example, for special materials, film coating, functional coatings and other fields, new designs of coating rods can provide more precise coating control.

In conclusion, as a tool for preparing coating films in the laboratory, coating rods play an important role in the research and application field of coating technology. By selecting and using coating rods rationally, researchers can explore different aspects of the coating process and achieve precise control and optimization of coating.